Understanding the market dynamics of 40ft reefer container prices involves a confluence of diverse factors. Notably, these containers are integral to the transportation industry, particularly for shipping perishable goods that require temperature control. With the global supply chain experiencing unprecedented disruptions, such as those seen during the COVID-19 pandemic, prices for these containers have seen significant fluctuations. The reasons behind these changes are multifaceted, encompassing manufacturing costs, global demand, and logistical challenges.

From an industry perspective, expertise in understanding these cost determinants is crucial for making informed purchasing decisions. Historically, the price of a 40ft reefer container was influenced heavily by the raw materials used in their construction, including the cost of steel and insulation materials. Additionally, technological advancements in refrigeration systems have introduced more sophisticated units, which, while more energy-efficient and reliable, also factor into the overall cost.

An authoritative voice in the field might suggest that another layer of complexity is added by the geographical disparities in container pricing. Factors such as port handling fees, tariffs, and the disparity in import-export practices contribute significantly to the regional differences in container pricing. Moreover, major shipping routes and their connectivity to the manufacturing hubs play a pivotal role in determining price variances, with containers often being more expensive in regions further away from these hubs.

Building trustworthiness with clients or industry stakeholders often involves leveraging both data and historical analysis to anticipate pricing trends. For instance, during peak seasons—such as harvest periods for agricultural products—the demand for reefer containers surges, resulting in price hikes. Anticipating these trends can provide a competitive advantage, enabling businesses to optimize their logistics and budgeting accordingly.

The expertise extends to understanding the impact of global trade policies as well. Recent shifts towards more protectionist trade policies in certain regions have led to increased tariffs and trade barriers, impacting the flow and availability of reefer containers. Businesses must stay informed about these developments to mitigate risks associated with unexpected cost increases, thereby maintaining their supply chain’s agility and efficiency.40ft reefer container price

Real experiences shared by logistics managers often emphasize the importance of maintaining strategic partnerships with container suppliers. These relationships can provide beneficial insights into market trends and offer better negotiating power when it comes to pricing. Furthermore, companies are exploring leasing options and second-hand markets as alternative strategies to manage costs effectively.

Innovation in reefer technology also impacts the cost structure, influencing not only the initial purchase price but also long-term operational costs, such as maintenance and energy consumption. With the growing emphasis on sustainability, newer models are being developed to minimize carbon footprints, thus appealing to environmentally conscious companies. However, the initial investment in these advanced models can be significant, prompting companies to weigh the long-term benefits against the upfront costs.

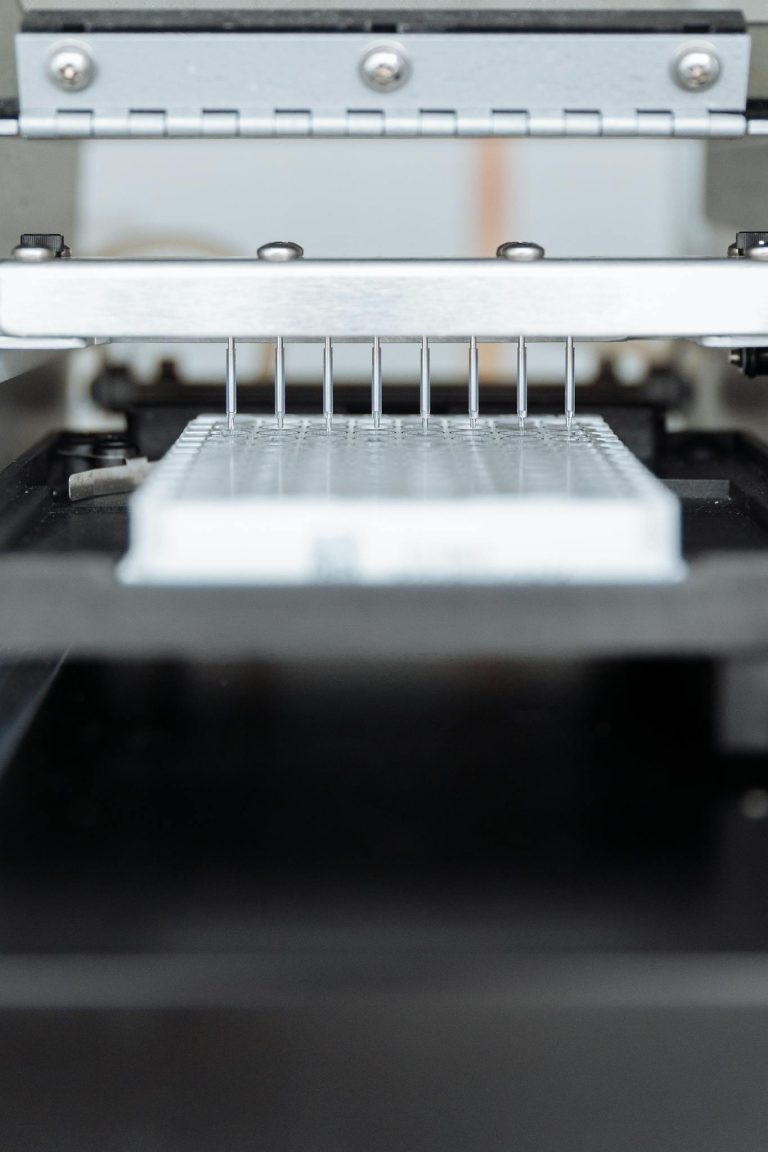

As digital transformation continues to influence every sector, the adoption of IoT (Internet of Things) in reefer containers is becoming prevalent. Smart containers equipped with sensors provide real-time data on temperature and humidity, ensuring optimal conditions for perishable goods. This technological leap, while enhancing operational efficiency, also introduces an added layer of cost due to the sophisticated equipment involved.

In conclusion, analyzing the 40ft reefer container price involves a nuanced understanding of various economic, technological, and geopolitical factors. Companies that harness this understanding can not only navigate the complexities of the global logistics landscape more effectively but also achieve greater cost efficiencies in their operations. Through informed decision-making rooted in industrial expertise, trustworthiness, and authoritative insights, businesses can optimize their supply chain strategies and maintain a competitive edge in an increasingly dynamic market.