Dangerous Goods Containers

Dangerous Goods Containers are prioritized in the industrial sector for carrying and storing hazardous or dangerous goods. Compliance must be strictly followed when dealing with hazardous materials, and failing to do so is not an option.

Established in 2008 and leveraging over 17 years of specialized expertise in custom container manufacturing, ZN MEOX has completed more than 1,500 projects globally. This deep experience allows us to create Dangerous Goods Containers (DG Containers) that lead the industry in safety, durability, and regulatory compliance.

Our DG containers are definitely not just modified shipping units; they are, in fact, purpose-built storage and transport vessels of the future. They are specially made to be explosion-proof to hold and separate hazardous liquids, solids, and gases safely anywhere in the world. supply chains. Partner with ZN MEOX for engineered safety and guaranteed peace of mind.

Each ZN MEOX Dangerous Goods container is precisely manufactured and undergoes testing to meet the necessary global standards, such as the structural standards of ISO 1496/1, as well as the specifications of the hazardous cargo by the UN Code. Our whole staff of certified engineers from inside, who are working in our ISO 9001:2015 certified plant, assemble all the units that, thus, by the way, are of the highest strength, safety, and tightness of all the transport means (sea, road, and rail).

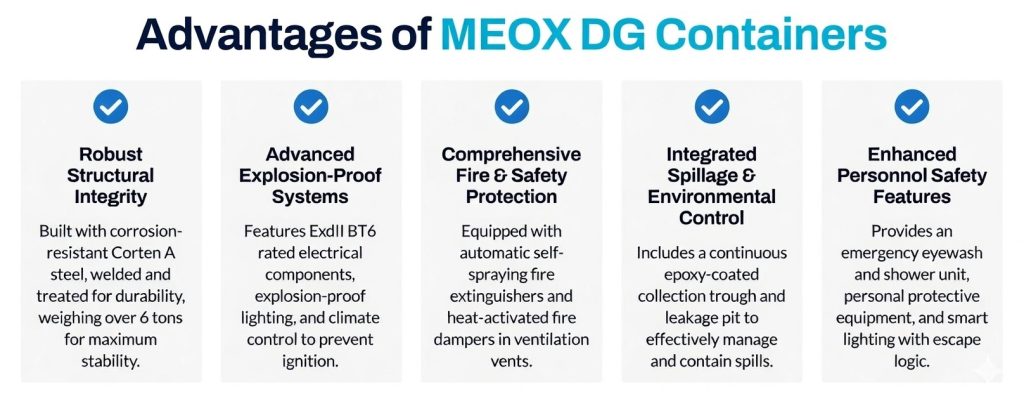

Integrated Safety Systems: Technical Specifications for ZN MEOX DG Containers

ZN MEOX Dangerous Goods Containers are high-spec, custom-made units. They entail the latest technology to guarantee the highest level of containment, security of operation, and durability over a long period, even in hard-to-handle hazardous environments.

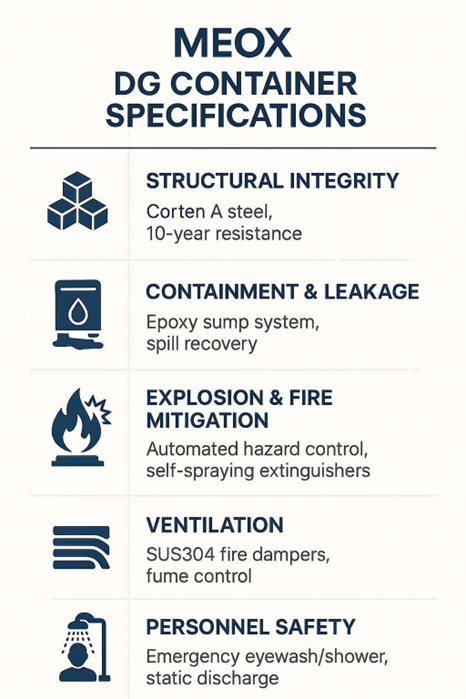

| Focus Area | Key Feature | Technical Specification & Safety Advantage |

| Structural Integrity & Longevity | Corten Steel & Multi-Layer Coating | Advantage: 10 Year Water Resistance. The framework is constructed from Corten A steel plate. Protection includes zinc-rich epoxy primer and a high-performance chlorinated rubber topcoat. The unit is certified to be water-resistant for at least 10 years. |

| Advanced Containment & Leakage Recovery | Integrated Epoxy Sump System | Advantage: Zero-Tolerance Spill Containment. A continuous liquid collection trough with an epoxy resin coating and a ≥ 2mm stainless steel cover is installed in the storage area. Leaked liquids are channeled via piping to a separate collection pit. |

| Explosion & Fire Mitigation | Active & Passive Explosion Protection | Advantage: Automated Hazard Control. The storage area is fitted with a critical explosion vent at the top. Includes 8 self-spraying dry powder fire extinguishers (6kg) that automatically spray when the temperature exceeds 70°C. All internal cameras are explosion-proof type. |

| Atmosphere & Ventilation | Controlled Fire-Dampened Ventilation | Advantage: Fume Control and Fire Isolation. The storage area has 8 air intake vents (250×250 mm) equipped with SUS304 stainless steel fire dampers. These dampers automatically close the ventilation system if the temperature reaches 70°C. |

| Personnel & Operational Safety | Emergency Eyewash/Shower & Static Discharge | Advantage: Immediate Personnel Decontamination. An emergency eyewash and shower unit is located near the fire door, reachable within 10 seconds. It provides stable water for at least 15 minutes. Electrostatic discharge devices are installed for personnel grounding before container entry. |

Dangerous Goods Container Features: Engineered for Safe Transport

The ZN MEOX Dangerous Goods Container is designed with the sole purpose of storing and transporting hazardous materials safely. It is equipped with essential safety features that meet globally recognized safety regulations and provide the highest level of containment.

Containment and Safety

Integrated Drip Tray (Sump): A drip tray is installed at the bottom of the container to properly catch any small drips of leaked hazardous liquid, thus avoiding spills to the environment and contamination.

Internal Protection: The container is fitted with an aluminium grating inside to serve as a firm surface and to stop the escape of waste by way of compression or blow.Operational Safety: The safety locks of special design, which can be opened from inside, are fixed on the container doors, thus ensuring the safety of the staff and protecting them from accidental entrapment.

Durability and Longevity

Guarantee of Structural Integrity: ZN MEOX is confident of its quality. A Formal 10-Year Water Resistance Warranty is given to our cutting-edge Corten steel construction and multi-layer coating, thus guaranteeing a long period of trouble-free use.

Corrosion and Wear Resistance: The container is equipped with a quality C3 paint for its protective layer.

High-Grade Coating: The protection film is 220 microns in thickness.

Custom Coating Options: ZN MEOX provides the option of changing to a higher-grade C4 or C5 coat to serve your needs in terms of the environment and industry.

Usability and Ventilation

Natural Air Circulation: There are larger vents and exhaust louvres on the two end doors of the container.

Ventilation Design: The layout ensures that the natural airflow is from the bottom to the top, which is a very suitable air circulation for chemically hazardous materials.

Thermal Insulation: The container structure is of insulated materials; thus, it provides good thermal insulation during transport.Internal Access: The drip tray has been fitted with the prefabricated walkways and the shelving bases to facilitate usability.

The ZN MEOX DG Container Fleet: Selecting the Right Solution

Defining Dangerous Goods (DG) Containers

Dangerous Goods Containers are specifically designed, purpose-built shipping units that are made to safely store and transport hazardous materials by sea, road, or rail. In contrast to regular intermodal containers, DG containers have essential safety features added to them in order to deal with the risks arising from their contents, thus guaranteeing the highest level of containment and compliance with regulations. DG containers are also called Hazardous Materials (Hazmat) Containers.

Our engineering practices are guided by mandatory global standards, including the International Maritime Dangerous Goods (IMDG) Code.

Learn more about the governing standards for hazardous cargo: International Maritime Dangerous Goods (IMDG) Code

DG Container Range: Capacity and Optimal Use

ZN MEOX products include all possible sizes of Dangerous Goods containers, thus they can satisfy any logistic demand, whether it is a small storage or a large-volume worldwide transport.

10ft DG Container (Agile Solution): The 10ft Dangerous Goods Container by ZN-MEOX is an agile option for smaller, high-value, or time-critical hazardous shipments. Essentially, this unit is perfect for Limited Quantities (LQ) of dangerous goods, high-value hazardous materials (e.g. certain chemicals, pharmaceuticals), rescue shipments, or transport of the last leg. What sets us apart is that it carries all the same traits of a larger model, such as a sturdy construction, UN certification, and tightly secured fittings, while being capable of easy handling and positioning in a cramped area due to its smaller size.

20ft DG Container (Industry Workhorse): The 20ft Dangerous Goods Container is the mainstay of hazardous logistics, combining a sizable capacity with worldwide adaptability. It is ideal for a wide range of packed, dangerous goods—drums, Intermediate Bulk Containers (IBCs), intermediate bulk packs, or palletized hazardous materials of various classes. What sets us apart is the fact that its standard ISO dimensions make it possible to be effortlessly incorporated into the worldwide shipping networks, thus being the best combination of volume, strength of the structure (stacking tested), and features of compliance for different requirements of the DG transport.

40ft DG Container (High Capacity): With the 40ft Dangerous Goods Container, you can greatly enhance the efficiency of large-volume hazardous shipments. It is essentially the usage of one unit for a large quantity of hazardous materials, oversized DG equipment, or consolidating multiple dangerous shipments that need segregation. What sets us apart is that we can offer the highest payload capacity while still adhering to essential safety standards, thus it is perfect for transport cost optimization per unit of a large shipment. There are also high-cube versions to offer additional height.

For niche applications that require unique dimensions or features, ZN-ZN MEOX provides tailored solutions, such as the specialized 8ft Dangerous Goods Container. The 8ft unit is ideal for extremely small quantities of dangerous goods, the transport of specialized equipment, internal site transfers, the secure storage of hazardous materials on-site, or particular route limitations. Our benefit is providing complete UN-certified DG safety in the tiniest feasible footprint. This choice is great when the standard sizes are too large, but safety regulations and container-grade security must be maintained.

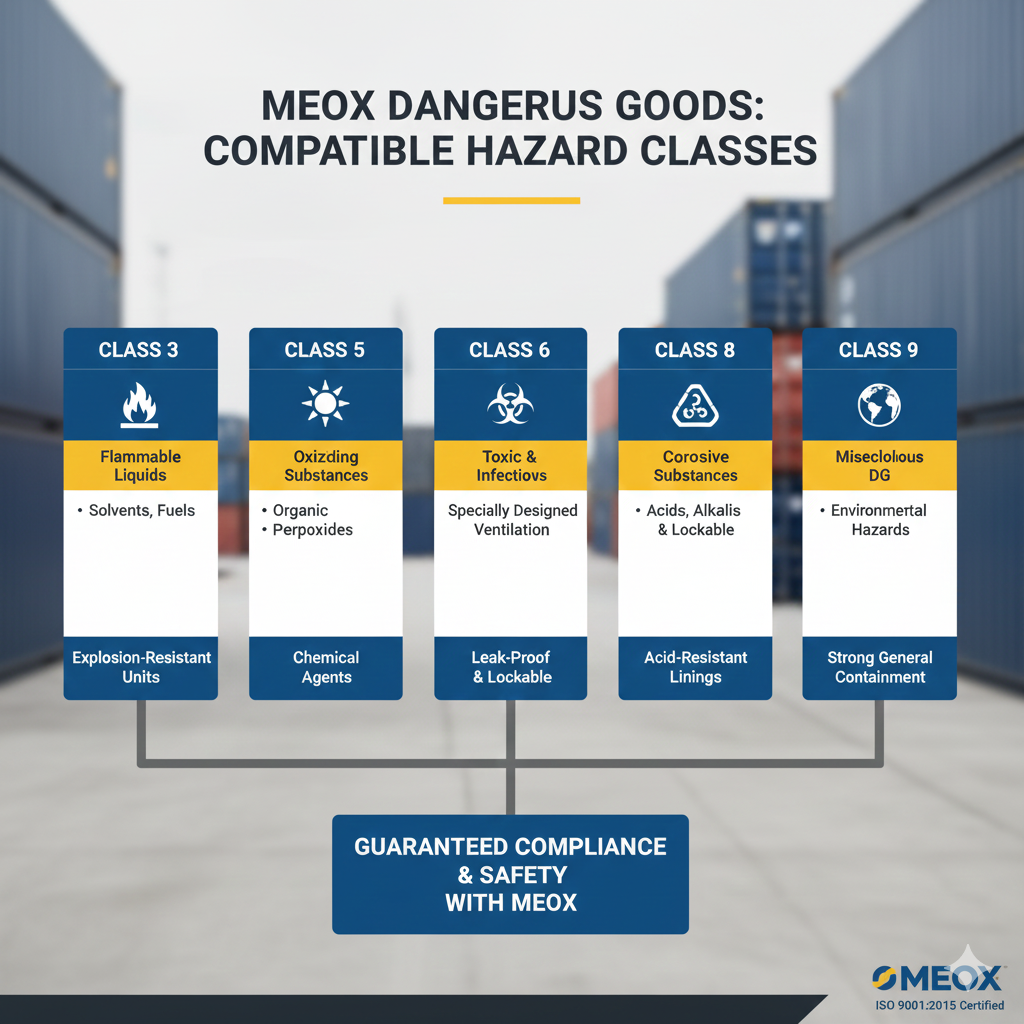

Compliance and Containment: Compatible Dangerous Goods Classes

Understanding which exact UN Dangerous Goods classes can be securely stored in a certified chemical storage container is the basis for safe and sound hazardous materials management. It is, therefore, essential for lab managers, industrial site operators, and transport companies that proper DG storage serves as a starting point for compliance with regulations, the safety of people, the protection of property, and environmental conservation.

ZN MEOX chemical storage containers are designed for the purpose with long-lasting, corrosion-resistant materials, strengthened seals, and built-in ventilation systems to hold various types of hazardous materials without the risk of leaks, fires, or unwanted chemical reactions.

Typically Managed Dangerous Goods Classes

Our certified chemical containers are routinely used for the following principal DG classes:

Class 3: Flammable Liquids – Securely store materials such as solvents, fuels, and alcohols that are highly flammable in explosion-resistant units.

Class 5: Oxidizing Substances and Organic Peroxides – Incorporates the installation of specially designed ventilation, which, by a significant reduction, decreases the risk of fire.

Class 6: Toxic and Infectious Substances – Employs leak-proof interiors and safe, lockable compartments for total containment.

Class 8: Corrosive Substances – Has acid-resistant linings that not only help in preventing structural changes but also in holding the caustic spills.

Class 9: Miscellaneous Dangerous Goods – Is able to accept substances such as materials that are hazardous to the environment or materials at elevated temperatures that need strong general containment.

Segregation and Risk Management

Customers must definitely check their local rules and do a proper risk assessment before they decide to store different classes of dangerous goods together in one place. In order to avoid the occurrence of hazardous reactions, it is a must that incompletely compatible materials are separated at all times. There are ZN MEOX chemical storage modules that come with the in-built separation sections, which are specially made to keep the multi-class storage situation in line with the requirements. Purchasing our engineered chemical storage containers is a great move not only for keeping in line with safety regulations but also for sustaining essential operational efficiency and tranquillity of mind.

Partner with ZN MEOX: Your Assurance in Hazardous Logistics

Choosing the right container for Dangerous Goods, be it an agile 10ft unit or a robust 40ft capacity, is not only a pivotal element for conforming to the law but also a preventive measure against accidents. ZN MEOX is not just a mere supplier of equipment; we deliver technically developed safety solutions that are in line with the intricacies of the international hazardous materials supply chain.

Commitment to Compliance and Quality

Every ZN MEOX DG container is manufactured and tested to meet rigorous UN standards, guaranteeing unparalleled durability, security, and integrity across all transport modalities (sea, road, and rail). Our commitment ensures that your investment provides long-term operational peace of mind.

Expert Guidance Available

Are you upgrading your facility or starting a new operation? It is very important to select the exact container for your particular DG class to ensure safety in the operation.

Get in touch with ZN MEOX today for professional advice and have a look at our compliant, easy-to-ship chemical storage solutions that are made just for your rigorous needs. Explore an in-depth guide to DG Container compliance and other related topics on the ZN MEOX Blog, click here.

To know more about the introduction of the DG containers, watch this video: