Thermal containers are an essential innovation, particularly in industries requiring temperature control for sensitive goods. With the increasing demand for efficient thermal insulation, the need for an authoritative guide on thermal containers becomes apparent.

Thermal containers, often synonymous with thermal insulation boxes, are primarily used for transporting perishable goods or temperature-sensitive materials. These containers play a critical role in maintaining the desired temperature range, which is crucial in sectors such as food logistics, pharmaceuticals, and biotechnology.

Experience in utilizing thermal containers reveals that the choice of material significantly impacts performance. Containers made from expanded polystyrene (EPS) or polyurethane are renowned for their superior insulation properties. These materials are adept at maintaining consistent temperatures over extended periods, thus ensuring the integrity of enclosed products.

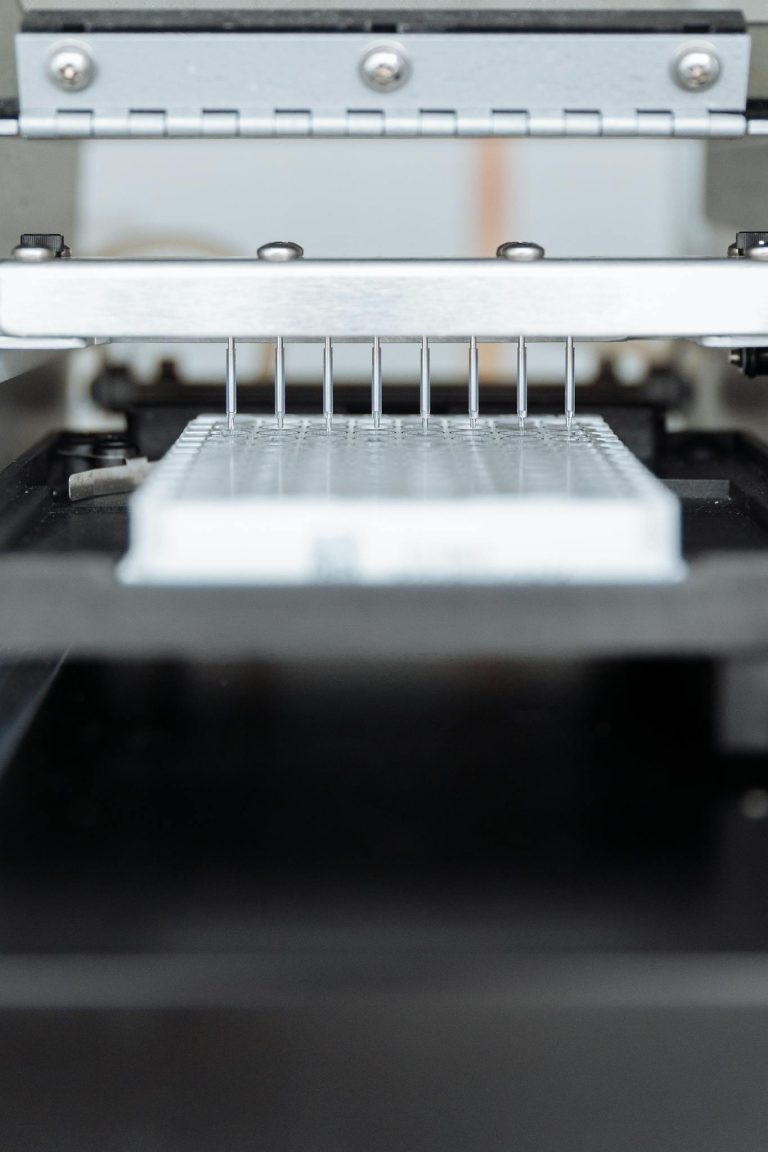

In the realm of pharmaceuticals, thermal containers are vital for the transport of vaccines and biologics. They help maintain the cold chain, a temperature-controlled supply chain crucial for preserving the efficacy of these products. Recent advancements have seen the introduction of phase change materials (PCMs) into thermal containers, which further optimize temperature control by absorbing or releasing heat at specific temperatures.

A significant challenge that users encounter with thermal containers is condensation, which can compromise insulation efficiency. Expertise in managing this issue involves incorporating materials with desiccant properties into the design, or employing vacuum insulation panels (VIPs) for superior performance.

Furthermore, innovations in thermal container technology have led to the development of GPS-enabled containers that provide real-time temperature and location tracking. This feature enhances trustworthiness and accountability in the supply chain, as stakeholders can monitor the conditions of the goods throughout the transportation process.thermal container

When selecting a thermal container, understanding the thermal performance is vital. This can be assessed through the R-value, a measure of insulation efficiency. A higher R-value indicates better insulating capability. It is also essential to consider the container’s sealing mechanism, as this significantly affects the overall thermal efficiency. Containers with airtight seals prevent external air from entering, thereby maintaining the desired internal temperature.

Authoritativeness in the field of thermal containers is demonstrated through compliance with industry standards such as the FDA, WHO, or IATA guidelines, depending on the region and purpose of use. These standards ensure that the containers meet the necessary requirements for safety and performance.

In the food industry, thermal containers are indispensable for maintaining the freshness of perishable items during transit. By keeping products at consistent temperatures, they prevent spoilage and extend shelf life. The use of thermal containers has become a standard practice among food delivery services, which underscores their increasing importance in the market.

When considering the lifecycle cost of thermal containers, it is important to evaluate not just the initial purchase price but also long-term savings accrued through reduced spoilage and increased efficiency. Some businesses have found that investing in premium containers with enhanced features significantly reduces wastage and product loss.

In conclusion, the proper selection and use of thermal containers can greatly enhance the efficiency and reliability of temperature-sensitive goods transportation. The ongoing advancements in material science, design innovation, and technology integration continue to improve their functionality. Whether in healthcare, food logistics, or other industries, thermal containers remain a critical component in maintaining product integrity, ultimately reflecting positively on brand reputation and customer satisfaction.

By understanding the intricate details and developments in thermal container technology, stakeholders can make informed decisions that not only enhance operational efficiency but also comply with the highest standards of quality assurance in the industry.