The rise of the container factory model represents a significant evolution in manufacturing, driven by the need for efficiency, flexibility, and sustainability. This innovative approach allows businesses to establish production facilities rapidly, anywhere in the world, by utilizing shipping containers as versatile building blocks.

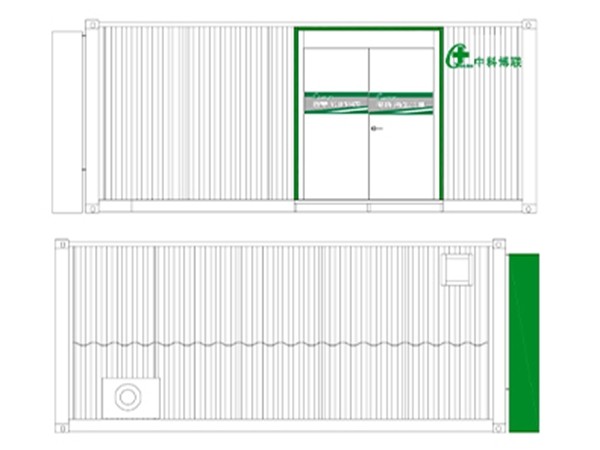

Container factories leverage the structural integrity and modularity of containers to create scalable manufacturing units. This approach not only cuts down the time and cost associated with constructing traditional facilities but also provides the flexibility to expand operations in response to market demand. For companies aiming to enter new markets or scale their production without massive upfront investments, container factories offer an optimal solution.

One of the standout advantages of container factories is their sustainability. These facilities make use of repurposed shipping containers, reducing waste and contributing to environmental conservation. By incorporating advanced eco-friendly technologies such as solar panels, rainwater collection, and energy-efficient systems, manufacturers ensure that their operations align with global sustainability goals. This aspect is increasingly important as consumers and governments demand greater environmental responsibility from businesses.

From an experiental perspective, manufacturers adopting container factories gain the ability to respond swiftly to market changes. For instance, during unexpected surges in product demand, additional production modules can be added with minimal disruption. The mobility of these containers also means that production can be relocated closer to target markets, reducing logistics costs and carbon footprints.container factory

With regard to expertise, successful implementation of container factories requires an understanding of modular construction, supply chain logistics, and lean manufacturing principles. Experts in these fields collaborate to design and optimize the layout of the factory, ensuring maximum efficiency and output quality. Companies often partner with specialized firms that have pioneered container-based solutions, benefiting from their deep industry insights and technical know-how.

Authoritativeness in the container factory niche is demonstrated by a company’s ability to consistently deliver high-quality products while maintaining operational flexibility. This involves rigorous quality control protocols and adopting cutting-edge manufacturing technologies. Businesses that excel in these areas not only enhance their reputation but also set industry standards, influencing the broader adoption of container-based manufacturing.

Trustworthiness is further established through transparent business practices and communication. Companies utilizing container factories often highlight their sustainable practices and efficiency gains, building trust with stakeholders who value corporate responsibility. Providing clear documentation and open channels for customer feedback helps reinforce the reliability and integrity of the production process.

In conclusion, container factories are reshaping the future of manufacturing with their unique blend of flexibility, sustainability, and cost-effectiveness. By combining practical experience with industry expertise, maintaining authoritative standards, and fostering trust, businesses can maximize the benefits of this innovative production method. As more industries recognize the potential of containerized solutions, those at the forefront will undoubtedly lead the charge toward a more adaptable and sustainable manufacturing paradigm.