A containerized water treatment plant is a portable and modular system designed to treat water efficiently. This innovative solution addresses the growing need for clean water in various settings, including remote areas and emergency situations. Housed within a standard shipping container, it offers unmatched convenience by simplifying transportation and installation processes.

The demand for such systems continues to rise globally due to their affordability, quick deployment, and ability to manage industrial wastewater effectively. The market for decentralized containerized water treatment solutions is projected to grow significantly, reaching $11.47 billion by 2030. These compact systems play a vital role in tackling water scarcity challenges while supporting sustainability efforts.

Key Takeaways

Containerized water treatment plants are portable systems that clean water. They work well in remote places and during emergencies.

These plants have a modular design, making them easy to set up. They can also grow bigger to handle more water if needed.

Energy-saving technology in these systems uses up to 40% less power. This helps save money over time.

These plants can clean many types of water, like salty or dirty water. This ensures people always have clean water to use.

Containerized systems are great for military, aid work, and factories. They give safe water quickly, even in tough conditions.

How Does A Containerized Water Treatment Plant Work?

Water treatment process

Water intake and pre-treatment

The water treatment process begins with the intake of raw water from a source such as a river, lake, or groundwater. Pre-treatment methods prepare the water for further purification. These methods often include chemical dosing to neutralize contaminants and sand filtration to remove larger particles. Raw water pumps transport the water into the system, ensuring a steady flow for subsequent stages.

Filtration and purification

Filtration plays a critical role in removing impurities. Various filter media, such as sand, gravel, and activated carbon, trap contaminants effectively. Advanced techniques like reverse osmosis (RO) and ultrafiltration refine the water further. RO membranes eliminate dissolved substances, including salts, making the system suitable for desalination. Ultrafiltration membranes capture smaller particles and microorganisms, enhancing water quality.

Disinfection and final treatment

Disinfection ensures the water is safe for consumption. Technologies like ultraviolet (UV) sterilization and ozone generation neutralize harmful microorganisms. UV light damages the genetic material of pathogens, while ozone acts as a powerful oxidizing agent to break down organic contaminants. These methods provide an additional layer of safety, ensuring the treated water meets health standards.

Modular system design

Pre-assembled components in the container

A containerized water treatment plant features pre-assembled components housed within a standard shipping container. These components include dosing tanks, media filtration vessels, and industrial reverse osmosis systems. The modular design simplifies transportation and installation. Operators can connect the inlet and outlet pipelines on-site, eliminating the need for extensive construction.

Plug-and-play functionality for rapid deployment

The plug-and-play functionality of these systems allows for quick deployment. Each module is designed to operate independently or as part of a larger system. This flexibility enables the plant to adapt to varying water demands and quality challenges. The modular design also supports scalability, making it easy to expand the system as needed.

Key Features Of A Containerized Water Treatment Plant

Portability and compact design

Standardized container sizes for easy transport

Containerized water treatment plants are designed to fit within standard shipping containers, making them highly portable. These containers come in various sizes to suit different project requirements. This standardization ensures compatibility with global transportation systems, including trucks, ships, and trains. Moving these systems to remote or disaster-stricken areas becomes seamless, enabling rapid deployment.

Minimal space requirements for installation

The compact design of these plants minimizes the space needed for installation. Unlike traditional water treatment facilities, which require extensive land and infrastructure, containerized systems can operate in confined spaces. This feature makes them ideal for urban areas, industrial sites, and temporary locations where space is limited.

Modularity and scalability

Customizable configurations for different water sources

The modular nature of containerized water treatment plants allows for tailored configurations. Each module can be customized to treat specific water sources, such as brackish water, seawater, or wastewater. This flexibility ensures optimal performance regardless of the water’s contamination level.

Containerized water treatment systems are pre-engineered and assembled off-site, significantly reducing installation time, which allows for quick deployment and faster access to clean water.

Ability to add or remove modules as needed

The modular design also supports scalability. Additional containers can be added to increase capacity as water demand grows. This approach eliminates the need for costly overhauls or new construction. The table below outlines the advantages of modularity:

Seamless Scaling: Modular design allows for easy addition of units to meet growing water demands without disruption.

Cost-Effectiveness: Communities can start small and expand as needed, making it financially viable.

Durability and efficiency

Robust construction for harsh environments

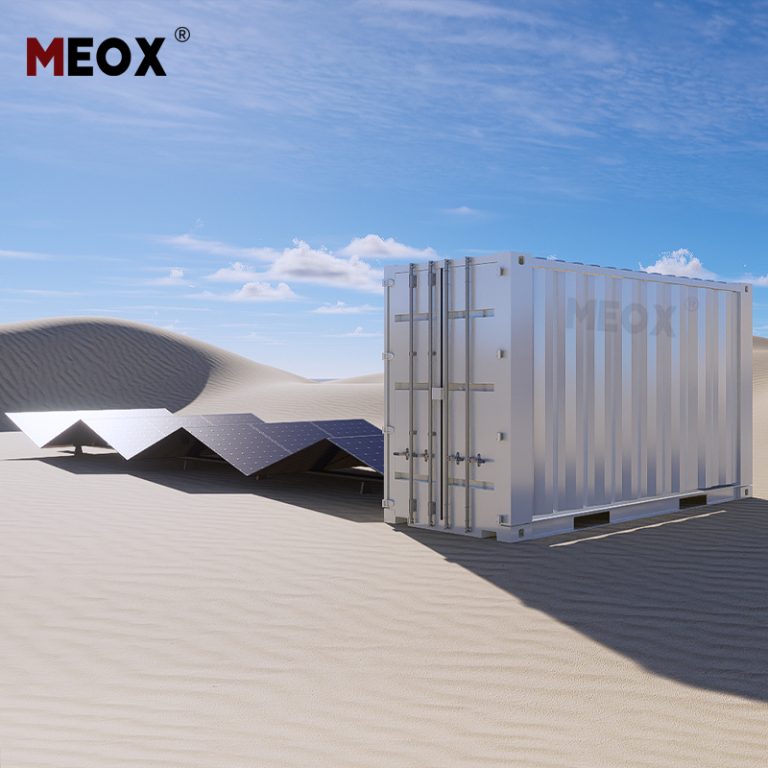

Containerized water treatment plants are built to withstand challenging conditions. Reinforced side and bottom plates in the water treatment section enhance durability, allowing the system to handle strong water pressure. These plants can operate reliably in extreme climates, from arid deserts to freezing tundras.

Energy-efficient operation

Energy efficiency is a key feature of these systems. The core membrane group, made of reinforced hollow fiber membrane, reduces energy consumption by approximately 40% compared to traditional systems. This technology also resists acids and alkalis, ensuring effective treatment with minimal energy use. Additionally, the design integrates seamlessly into existing systems, further enhancing efficiency.

Benefits Of A Containerized Water Treatment Plant

Cost-effectiveness

Lower initial investment compared to traditional plants

A containerized water treatment plant offers significant cost advantages over traditional facilities. Its streamlined production process and pre-assembled design eliminate the need for extensive construction. This reduces the initial investment required to set up the system. The smaller infrastructure requirements further contribute to affordability, making it an attractive option for communities and industries with limited budgets.

The compact nature of these plants minimizes land acquisition costs.

Pre-engineered systems reduce labor expenses during installation.

Faster production times lower overall project timelines and associated costs.

However, customization costs for specific water treatment needs can sometimes increase the initial investment. Despite this, the long-term savings often outweigh these expenses.

Reduced operational and maintenance costs

Operational efficiency is another key benefit. Containerized systems use energy-efficient technologies, which lower electricity consumption. Their modular design simplifies maintenance, as individual components can be serviced or replaced without disrupting the entire system. This reduces downtime and maintenance expenses, ensuring cost-effective operation over the plant’s lifecycle.

Quick and easy installation

Pre-assembled systems reduce setup time

The pre-assembled nature of a containerized water treatment plant significantly shortens installation time. All components are integrated into the container before delivery, allowing operators to focus on connecting the inlet and outlet pipelines on-site. This plug-and-play functionality ensures the system becomes operational within days rather than months.

Minimal site preparation required

These plants require minimal site preparation, as they do not depend on extensive infrastructure. Unlike traditional facilities, which often need large-scale excavation and foundation work, containerized systems can be placed on flat surfaces. This feature makes them ideal for temporary or emergency applications where time is critical.

Adaptability to various environments

Suitable for remote or disaster-stricken areas

A containerized water treatment plant excels in challenging environments. Its portability allows it to be transported to remote or off-grid locations where access to clean water is limited. During natural disasters, these systems can be deployed quickly to provide immediate relief. Their compact design also suits military operations and humanitarian aid missions, where mobility and efficiency are essential.

Construction sites benefit from on-site clean water supply.

Refugee camps and temporary settlements gain access to safe drinking water.

Mining and industrial sites ensure steady water availability.

Can handle different water sources, including brackish or wastewater

The modular design of these plants enables them to treat various water sources effectively. Whether dealing with brackish water, seawater, or wastewater, the system can be customized to meet specific treatment requirements. This versatility ensures reliable performance across diverse applications, from industrial processes to community water supply.

The ability to adapt to different environments and water sources makes containerized water treatment plants a versatile and practical solution for global water challenges.

Applications Of Containerized Water Treatment Plants

Remote and rural areas

Providing clean water to communities without infrastructure

Containerized water treatment plants play a crucial role in addressing water scarcity in remote and rural areas. Many communities in these regions lack the infrastructure needed for traditional water treatment facilities. These portable systems provide an efficient solution by delivering clean water directly to underserved populations. Their modular design allows them to operate independently, even in off-grid locations.

For example, a containerized water treatment plant can treat groundwater or surface water to meet drinking water standards. This ensures that residents in isolated areas gain access to safe water without requiring extensive infrastructure investments. Additionally, the compact design of these systems makes them suitable for small villages or temporary settlements where space is limited.

Emergency and disaster relief

Rapid deployment in crisis situations

In emergency scenarios, containerized water treatment plants offer a lifeline by providing immediate access to clean water. Their self-contained design enables rapid deployment to disaster-stricken areas, where traditional water systems may be damaged or unavailable. These systems can become operational within weeks, ensuring that affected populations receive clean water quickly.

Containerized systems have been used effectively during natural disasters like hurricanes and earthquakes.

Their compact structure allows them to function in areas with limited space or infrastructure.

By decentralizing water treatment, they reduce the risk of widespread water shortages during crises.

These plants also enhance resilience against unpredictable weather patterns and water scarcity. Their ability to treat various water sources, including brackish or contaminated water, ensures reliable performance in challenging conditions.

Industrial and commercial use

Supporting industries like mining, oil and gas, and construction

Industries rely on containerized water treatment plants to meet their specific water needs. These systems are particularly valuable in sectors such as mining, oil and gas, and construction. At mining sites, they provide a reliable water supply for operations and worker accommodations. In the oil and gas industry, they treat wastewater to meet environmental standards, ensuring compliance with regulations.

Construction sites benefit from on-site water treatment, reducing reliance on external water sources.

Temporary settlements, such as worker camps, gain access to clean water through these portable systems.

Industrial sites customize these plants to handle unique water treatment challenges, such as removing heavy metals or treating high-salinity water.

The adaptability of containerized water treatment plants makes them an essential tool for industries operating in remote or environmentally sensitive areas. Their modular design allows for easy scaling, ensuring they meet the growing demands of industrial operations.

Military and humanitarian missions

Supplying water to troops or aid organizations in the field

Military operations and humanitarian missions often take place in remote or resource-limited areas. Access to clean water becomes a critical challenge in such environments. A containerized water treatment plant provides an effective solution by delivering safe and reliable water supplies directly to the field. Its portability and modular design allow for rapid deployment, ensuring that troops and aid workers have access to clean water wherever they are stationed.

These systems are pre-assembled and housed in standard shipping containers, making them easy to transport via trucks, ships, or aircraft. Once on-site, they require minimal setup. Operators can connect the inlet and outlet pipelines quickly, enabling the system to become operational within hours. This efficiency is vital during emergencies or in conflict zones where time and resources are limited.

The adaptability of a containerized water treatment plant ensures it can handle various water sources, including brackish water, surface water, or even contaminated supplies. Advanced filtration and disinfection technologies, such as reverse osmosis and ultraviolet sterilization, ensure the treated water meets stringent safety standards. This capability is particularly important for maintaining the health and well-being of personnel in challenging conditions.

Humanitarian organizations also benefit from these systems during disaster relief efforts. Natural disasters often disrupt existing water infrastructure, leaving affected populations vulnerable to waterborne diseases. A containerized water treatment plant can provide immediate relief by supplying clean water to temporary shelters, refugee camps, or field hospitals. Its compact design allows it to operate in confined spaces, making it suitable for urban disaster zones or remote rural areas.

The durability of these systems ensures reliable performance in extreme climates, from scorching deserts to freezing tundras. Their robust construction and energy-efficient operation make them a sustainable choice for long-term missions. By addressing the critical need for clean water, these plants play a vital role in supporting military and humanitarian efforts worldwide.

FAQ About Containerized Water Treatment Plants

What is the lifespan of a containerized water treatment plant?

The lifespan of a containerized water treatment plant typically ranges from 10 to 20 years. Proper maintenance, regular inspections, and timely replacement of consumables like filters and membranes can extend its operational life.

Can containerized water treatment plants handle extreme weather conditions?

Yes, these systems are designed for durability. Reinforced containers and robust construction allow them to operate in harsh environments, including extreme heat, cold, or high humidity.

How much water can a containerized plant treat daily?

The treatment capacity depends on the system’s configuration. Modular designs can handle projects ranging from 100 to 10,000 tons of water per day, making them suitable for small communities or large industrial applications.

Are containerized water treatment plants energy-efficient?

Yes, these systems use advanced technologies like energy-efficient membranes and optimized filtration processes. This reduces electricity consumption by up to 40% compared to traditional water treatment methods.

Can the system be customized for specific needs?

Yes, our containerized water treatment plants offer customizable options. Users can tailor configurations to treat various water sources, add insulation, or include noise reduction features based on specific project requirements.