A container factory represents a modern marvel in the manufacturing industry, embodying innovation, efficiency, and sustainability. These specialized facilities have become essential due to the escalating demand for shipping containers, which play a pivotal role in global trade and logistics. The unique nature of a container factory lies in its ability to transform raw steel into sturdy, versatile products that can be used across several sectors, including cargo transport, modular construction, and sustainable housing solutions.

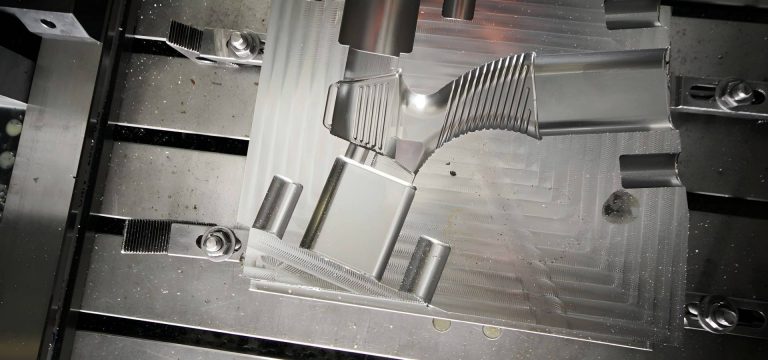

The process begins with the precise cutting of steel sheets, which are then assembled to form the walls, roof, and floor of the containers. The welding processes employed in these factories are state-of-the-art, ensuring the strength and durability required for containers to withstand harsh environmental conditions. Advanced machinery and robotics play a significant role, enhancing production speed and accuracy while reducing human errors.

In terms of expertise, these factories are staffed by skilled professionals who possess deep knowledge of metallurgy, engineering, and industrial design. Such expertise ensures high-quality production standards are met, crucial for maintaining the structural integrity of the containers. Furthermore, continuous training programs help workers to stay abreast of the latest technological advancements and safety protocols, fostering an environment of ongoing improvement and innovation.

A critical aspect of a container factory’s authoritative reputation is its adherence to international standards and certifications, such as ISO 9001 for quality management and ISO 14001 for environmental management. These certifications not only demonstrate a commitment to excellence but also ensure compliance with safety, quality, and environmental preservation standards. Additionally, partnerships with reputable logistics companies and construction firms further consolidate their standing in the industry.container factory

Trustworthiness in container production is established through rigorous quality assurance processes. Each container undergoes extensive testing for load capacity, waterproofing, and corrosion resistance. The use of high-grade Corten steel, known for its enhanced weathering resistance, enhances the lifespan of containers, making them a reliable choice for various applications. Customer feedback is actively sought and leveraged to refine and personalize production practices, cementing client trust.

With growing environmental concerns, many container factories are now investing in sustainable practices. This includes recycling scrap materials, implementing energy-efficient production processes, and exploring eco-friendly coatings that reduce harmful emissions during manufacturing. By focusing on sustainability, these factories not only contribute to environmental conservation but open up new opportunities in the green logistics and construction sectors.

Innovation continues to drive the industry, with container factories exploring the development of smart containers equipped with IoT devices that offer real-time tracking, temperature monitoring, and enhanced security features. Such advancements not only enhance the product offering but also create additional value for clients who require sophisticated solutions for their logistical needs.

In summary, a container factory is a complex ecosystem where advanced technology, professional expertise, and sustainability practices converge to produce robust and reliable containers essential for today’s logistics and construction industries. Their commitment to quality, innovation, and environmental stewardship ensures they remain at the forefront of global manufacturing standards, delivering products that clients can rely on for durability, versatility, and performance.