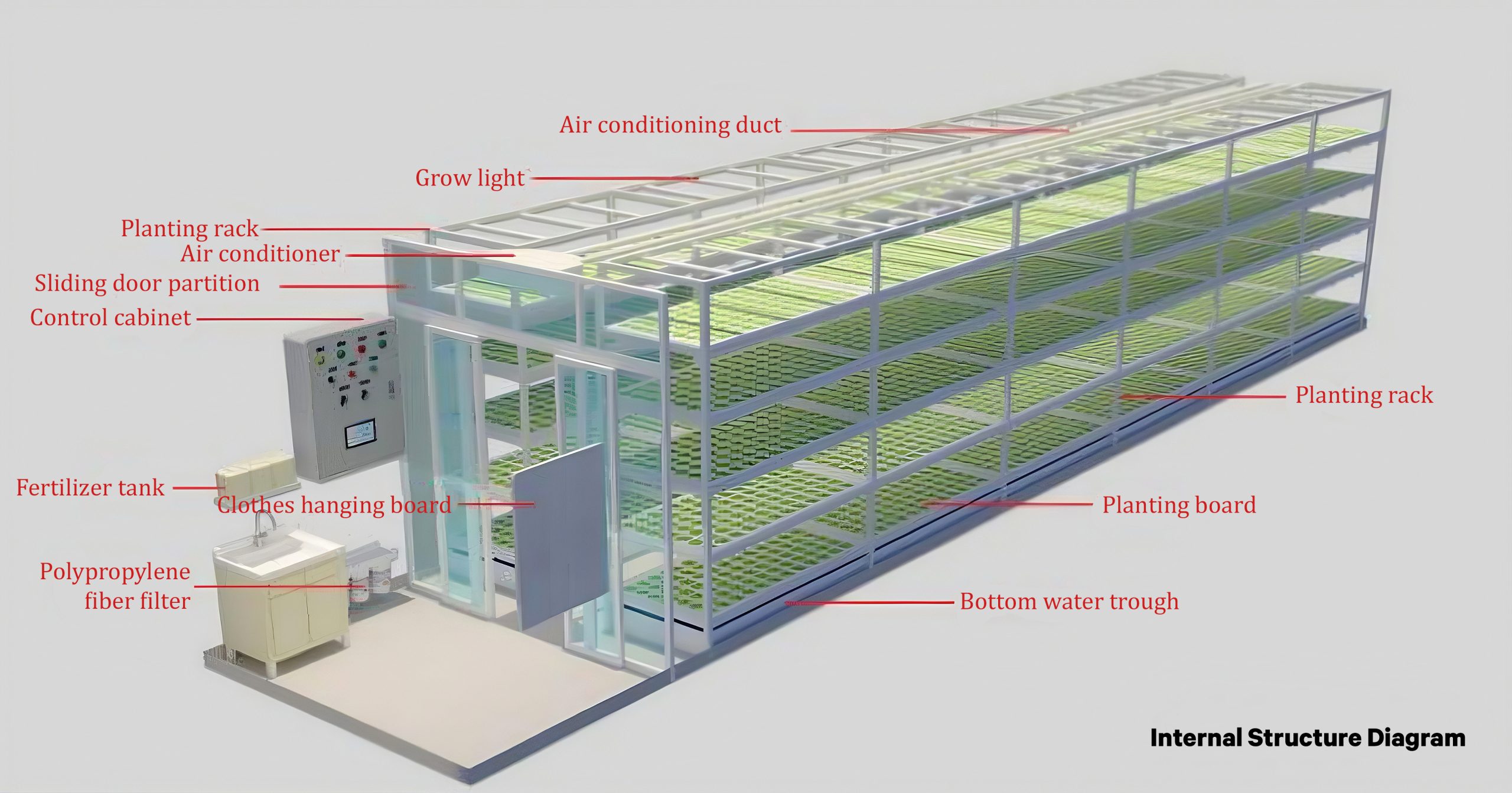

Planting Container

The planting container is a closed cultivation system that enables automatic control of the growing environment. It is equipped with a comprehensive automated environmental monitoring system that monitors data such as internal and external temperatures, humidity, and CO₂ concentration. It provides automatic closed-loop control of lighting, CO₂ air conditioning, fans, and water pumps. This allows growers to achieve stable year-round vegetable production.

Planting Container Features

- Highly adaptable; not affected by temperature and humidity variations, altitude, or harsh climates.

- Modular design with a high-strength container body for easy transport.

- Uses an automatic water-and-fertilizer circulation system to save labor and enable intelligent production.

- High strength, simple appearance, easy maintenance, and low upkeep costs.

- Artificial lighting uses spectra optimized for plant growth, eliminating the need for sunlight.

- Constructed from eco-friendly, energy-saving materials for efficient and stable production.

- Different growth modes can be used depending on crop varieties, enabling simplified, user‑friendly agricultural production.

- Detachable planting racks that can be freely arranged and designed from low to high according to plant size.

- Multiple planting containers can be used in combination—one for seedling cultivation and others for planting, enabling assembly‑line operation.

- Combined with small seeders and automatic packaging machines to improve efficiency and create scalable farms.

The container is clean and sealed, enabling the production of organic vegetables with zero pesticide residue; no pesticides are required, ensuring food safety. Custom designs are available based on customer needs and intended use, such as forage, microgreens, nursery stock, and medicinal herbs; also suitable for special applications like school practice, border outposts, and ocean‑going cargo vessels.

Planting Container System

- The complete control and cultivation system of the planting container is integrated into a single container or a similar fully enclosed environment. It combines the safety, efficiency, and precision of a plant factory with the mobility, flexibility, and sealed nature of a container. It is easy to transport and can begin operation immediately upon connection to water and power at the destination.

- Uses the commonly used 40-foot standard ISO refrigerated container, which is strong, durable, and easy to repair. It meets ISO standards and is suitable for sea and inland transportation.

Planting Container Control System

Independently developed

The control system uses a newly developed integrated control platform that adopts advanced international automation technologies. Combined with the company’s years of cultivation experience, it is specifically developed to optimize conditions for plant growth.

Intelligent control

The control system can monitor and automatically control environmental factors in real time, including temperature, humidity, ventilation, light cycle, light intensity, CO₂ concentration, nutrient solution EC and pH values, liquid level, and liquid temperature.

Easy to use

The human-machine interface is simple and user‑friendly, and operates reliably. The system complements container operation, maintenance, and management, and full automation enables unmanned operation.

Environmental Management System

1. Air Conditioning System

Equipped with one 3P ducted air conditioner, with ducts connected to the indoor circulation vents and controlled via the main control system. It can maintain daytime temperatures at 24–26°C and nighttime temperatures at 16–18°C to simulate natural temperature differences, which is beneficial for healthy crop growth.

2. Air Circulation System

The air circulation system includes intake fans, exhaust fans, top circulation fans, and a gentle breeze system. It can intelligently regulate the indoor climate and CO₂ levels based on indoor and outdoor temperature, humidity, and CO₂ data, thereby saving energy. The gentle breeze system simulates natural breezes to promote healthy crop growth and improve indoor air circulation.

Planting Container Nutrient Solution Formulation

Independently developed

The nutrient formulation is a dedicated NFT hydroponic system with four fertilization channels, precise peristaltic pump dosing, and each channel is equipped with a 10 L fertilizer tank.

Precise formulation

The automated fertilization system, combined with years of crop cultivation and management experience, has produced a specialized water‑and‑fertilizer formulation system for plant factories. Combined with EC/pH sensors, dosing precision can reach milliliter-level accuracy.

Easy to use

The fertilization system is simple to use; the user only needs to input a setpoint, and the system performs precise calculations to achieve accurate dosing.

Planting Container Water Circulation and Cultivation

Water Circulation System

Two 10-meter-long water tanks are installed beneath the growing racks, with a total water capacity of 2,600 kg. The tanks contain a circulation pump and support optional equipment such as inline UV sterilization lamps and oxygenation devices.

Cultivation System

The cultivation uses planting trays with float boards. The growth chamber contains 10 layers of planting trays, each with an independent water supply valve and drainage pipe. Each tray measures 1600 mm × 760 mm, and all trays together can grow up to 5,800 heads of lettuce simultaneously. The planting rack uses a patented column‑free design with advantages including a simple structure, stability, and strong customizable expandability.

Planting Container Lighting System

Simulated natural lighting

LED grow lights are installed above each layer of planting trays. Each layer’s lights can be controlled independently, with manual and automatic modes available. The main control system can automatically set the LED on/off times to simulate sunrise and sunset.

Technical Specifications

| Name | Specification (may vary by configuration) |

| Total power consumption | Up to approx. 9000 W |

| Container specification | 40 ft (internal dimensions: W 2.3 m × H 2.6 m × L 11.9 m) |

| Planting rack | 304 stainless steel frame |

| Planting trough | 1600 × 760 × 800 mm |

| Planting board | 1600 × 760 × 2 mm, 98 holes |

| Grow light | LED 24 V, 22 W/m |

| Water supply & return | PVC piping |

| Water tank | Food-grade 304 stainless steel |

| Water pump | AC 220 V, 15000 L/h, head 8 m |

| Name | Specification (may vary by configuration) |

| Fertilizer dosing channels | Medical-grade peristaltic pump(s) |

| Fertilizer tank | 10 L |

| Control cabinet | Integrated |

| Controller | Integrated embedded logic programmable controller |

| Touchscreen | Industrial 10-inch touchscreen |

| CO₂ (optional) | 10 L steel cylinder |

| Gentle-breeze system | 220 V, 40 W, 5.3 m³/h (simulates natural breeze) |

| Fan | 220 V, 30 W, 204 m³/h |

| Air conditioner | Cooling & heating type: cooling 7200 W, heating 7900 W |