PROFESSIONAL R&D TEAM

A research and development team with over ten years of experience in producing and designing special containers.

INDUSTRY CERTIFICATION

We have obtained the product and enterprise system certifications such as CE, ISO 9001, ISO 14001, BV (Bureau Veritas), etc.

FIVE STAR AFTER-SALES SERVICE

We have obtained the certification through the “Product After-sales Service Evaluation System” GB/T 27922-2011.

ABOUT ZN MEOX

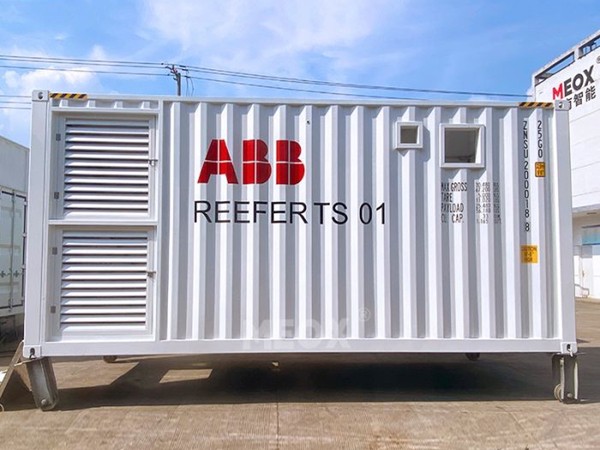

MEOX specializes in the integration of specialized equipment containers, offering a wide range of customized containers and high-end smart modular container homes for sale. This includes specialized solutions like solar containers. As a Special Container Manufacturer, we take pride in our capacity to tailor solutions to your specific needs. With a factory covering over 20,000 square meters and export operations in more than 50 countries, MEOX is equipped to deliver high-quality container solutions globally. Our team of seasoned experts and professional engineers is dedicated to ensuring the success of your specialized container projects.

At MEOX, we are committed to the belief: “Carrying dreams and creating the future.” Let our containers carry your dreams, reaching every corner of the world. As a Special Container Manufacturer, we ensure every project is handled with utmost precision.

Container Category

Owning to its extensive experience, MEOX is able to provide special containers and logistics equipment solutions to meet the demands of the most demanding sectors of the market, including customized shipping containers, energy storage containers, equipment containers, and reefer containers.

Solutions

When it comes to logistics, one-size-fits-all approaches are just not effective. Every industry has unique needs of its own. We can work with you to provide the ideal bulk container solution for anything that you need. Unlike stand-alone solutions, our integrated solutions are tailored to your complete supply chain. MEOX provides container projects for logistic solutions to any destination.

Freight Transport Solutions

Special containers can also be used as energy storage containers for storing electricity, balancing grid loads…

Energy Storage Solutions

Some special items have dimensions, weights, or loading methods that exceed the capacity or adaptability…

Special Equipment Solutions

With the development of the economy and technological progress, the use of large equipment is no longer limited…

Hurricane-Rated Modular Home

This self-use home is engineered to withstand hurricanes up to 185 mph, fully complies with U.S. electrical…

Mining Camp Accommodation

Mining accommodation units in Western Australia, customized in RAL 3009, compliant with Australian standards…

Solar Container

In 2025, three mining units in Bulgaria will use 147 kW solar and 215 kWh storage, off-grid or grid-connected, EU…

Blog & News

Global logistics never stops developing, thus we always provide the recent news and media. You can find all of the most recent press releases, articles, brochures, and images of MEOX and the logistics industry here. Find out about our services and current logistic issues by exploring and learning our news and blog section.