You can see hazardous waste storage containers changing quickly because of new rules. The market will go from USD 1.5 billion in 2023 to almost USD 2.7 billion by 2032. New ideas are very important. The latest trends focus on safety, being good for the environment, and smart design. Hazardous waste management now needs better ways and always getting better.

Key Takeaways

Smart technologies like IoT sensors and AI make hazardous waste containers safer. They help lower costs. They also help companies follow strict rules.

Using sustainable materials and designs helps cut down on pollution. It saves money in the long run. It also helps protect the environment.

Following new rules and doing regular inspections keeps your business safe. It helps you avoid expensive fines.

Hazardous Waste Storage Containers: 2025 Trends

Smart Technologies and IoT Integration

The hazardous waste containers market is changing quickly with new technology. In 2025, smart technologies and IoT are very important for the industry. Many companies use AI-driven sorting and IoT sensors to watch hazardous waste storage containers. These sensors check temperature, fill levels, and where each container is. You can see the status of your hazardous waste storage containers right away. This helps you stop overflows and accidents.

Smart hazardous waste storage containers help you follow strict rules. Digital tracking systems show where your waste goes from start to finish. Automated alerts tell you when a container needs help or when rules change. This lowers the chance of fines and keeps your business safe. In Barcelona, smart bins with sensors helped cut collection trips by 40%. This saved money and made the streets cleaner.

Tip: Using IoT sensors to watch in real time can stop costly mistakes and keep your team safer.

Here is a table that shows the good things about smart hazardous waste storage containers:

Benefit Category | Description | Example/Impact |

|---|---|---|

Operational Efficiency | Sensors help collect only when needed | Up to 40% fewer collection trips |

Cost Savings | Better routes and timing save fuel and work costs | 20-30% savings in collection expenses |

Environmental Impact | Fewer trips mean less pollution and cleaner places | Cleaner streets, lower emissions |

Compliance | Tracking stops fines for breaking rules | Up to $75,000 saved in fines |

Now, the hazardous waste containers market wants more smart features. You can use AI to sort waste and IoT to track containers. These new ideas help you handle hazardous waste storage containers safely and easily. Many businesses say they recycle more and spend less after using these smart tools.

Sustainable Materials and Design

Sustainability is a big trend in the hazardous waste containers industry. You want hazardous waste storage containers that protect the environment and follow new rules. Many companies pick containers made from recycled steel, strong composites, or materials that are responsibly sourced. These materials last longer and use fewer new resources.

Using sustainable materials helps lower greenhouse gas emissions and cuts pollution. Recycling hazardous waste storage containers means less waste goes to landfills or gets burned. This keeps air, water, and soil cleaner. Sustainable design also helps the circular economy. You can reuse or return containers, which means less waste and more savings.

Here are some main benefits of sustainable hazardous waste storage containers:

Use fewer raw materials and less energy

Lower greenhouse gas emissions

Help follow rules and support circular economy goals

Use resources better and make less waste

You might worry that sustainable materials cost more. At first, these containers can be more expensive. But you often save money over time. You pay less for waste disposal and avoid fines. Working with experts in sustainable packaging can help you design containers that use less material but still keep your hazardous waste safe. Many companies find that buying in bulk and better design saves even more money.

Note: Picking sustainable hazardous waste storage containers helps your business reach environmental goals and can save money in the long run.

The hazardous waste containers market now looks for new ideas in materials and design. You see more containers that can be reused, recycled, and made for special types of hazardous waste. These trends show the hazardous waste containers industry is moving toward safer, greener, and smarter ways.

Regulatory Drivers and Compliance

Evolving Environmental Standards

Rules for hazardous waste storage containers change every year. In 2025, the government made these rules even stricter. California changed its rules to match the EPA Generator Improvements Rule. Now, you must use new definitions and more generator categories. These changes affect how you label, store, and move hazardous waste.

Now, you must track when you start storing waste and follow time limits. Large Quantity Generators can store waste for 90 days. Small Quantity Generators get 180 or 270 days. If you forget or write the wrong start date, you could get in trouble. You must check central accumulation areas every week. Keep containers closed unless you are adding or taking out waste.

Note: If you do not follow the rules, you can get fined over $81,000 for each day. One company had to pay $9.5 million for not storing waste right and missing paperwork.

New standards let you use more flexible cleanup options. The EPA and states can let you use special permits or temporary units for cleanup. This helps you change your container design and how you use it to meet all rules. Always check for new environmental rules so you do not break them.

Inspection and Safety Protocols

You must follow strict inspection and safety steps to keep waste safe. Weekly checks help you find leaks or damage early. Here is a simple checklist you can use:

Look for cracks, dents, rust, or swelling on containers.

Make sure hazard labels and instructions are easy to see.

Check seals, caps, and valves for leaks or if they are brittle.

Listen for hissing and smell for chemicals, using PPE.

Check expiration dates on gas cylinders and other containers.

Use leak detectors for high-risk materials.

Tag and remove any damaged containers right away.

You must also teach your team how to handle emergencies and waste safely. Keep good records of all checks and training. Use the right containers for the type of hazardous waste you have. Always follow rules for storing different wastes and keeping them apart.

Inspection Task | Frequency | Regulation Reference |

|---|---|---|

Visual inspection of containers | Weekly | 22 CCR §66262.16(b)(2)(D) |

Employee training | Ongoing | OSHA 29 CFR 1910.120 |

Record-keeping | Ongoing | EPA RCRA |

Following the rules keeps your business and the environment safe. Regular checks and training lower risks and help you avoid big fines.

MEOX Dangerous Goods Container Innovations

Safety Features and Certifications

You need strong safety features when working with hazardous materials. MEOX dangerous goods containers use corten steel. This steel does not rust easily and can take hard hits. It keeps your hazardous waste safe when you move or store it. Inside, special linings stop leaks and keep things clean. These linings give your cargo extra protection.

Good ventilation is very important. MEOX containers have systems that let gases out safely. This lowers the chance of fire or explosion. Leak-proof seals, like rubber gaskets and welded seams, keep hazardous materials inside. You do not have to worry about spills or leaks hurting people or the environment.

Every container follows strict international rules. You will see clear labels, hazard symbols, and emergency instructions on each one. These markings follow rules from the UN, IMDG, and IATA. MEOX containers also have official certification marks, like UN numbers and approval stamps. These show the containers passed hard tests for shock, vibration, and pressure.

Here are some main certifications and standards these containers meet:

UN Model Regulations for dangerous goods

US 49 CFR Part 173

IATA Dangerous Goods Regulations (DGR)

IMDG Code for sea transport

AS 1940:2017 and AS 3780:2023 for chemical storage

ISO 9001 for quality management

MEOX uses new technology like GPS tracking. You can watch your container in real time. This helps you keep track of your hazardous waste and act fast if something goes wrong. Certified experts design and test each container. They use their skills to make sure every unit meets the latest safety and compliance needs.

Tip: Always check for certification marks and clear hazard labels before using any hazardous waste storage container. This makes sure you follow legal and safety rules.

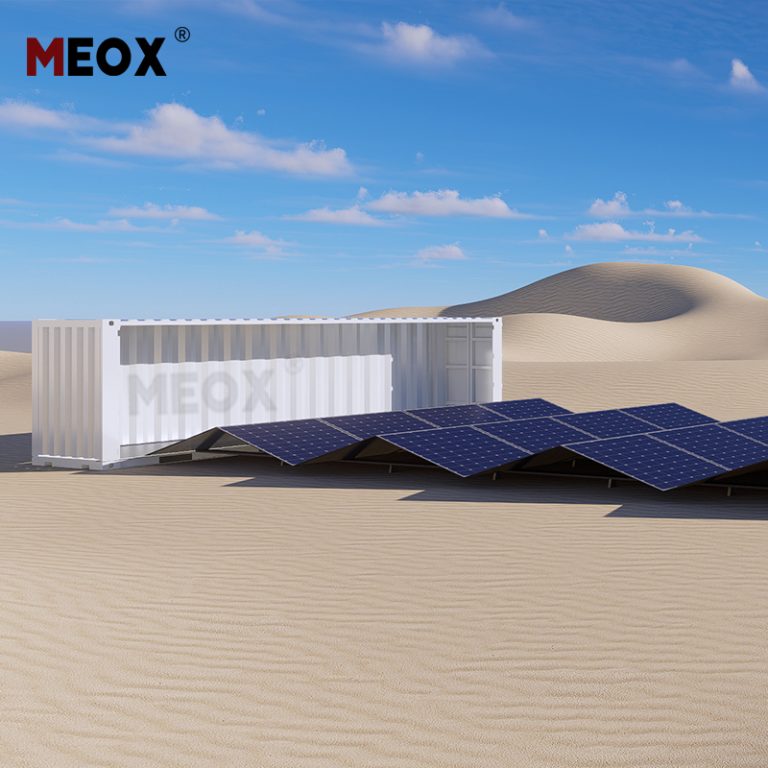

Customization and Application Flexibility

Different industries need different things. You might need a container for chemicals, energy storage, or a mobile lab. MEOX lets you customize your hazardous waste storage containers in many ways. You can pick the size, color, and even add your company logo. This helps match your container to your brand or project.

Here is a table that shows some main customization options:

Customization Aspect | Details |

|---|---|

External Dimensions | Choose length, width, and height to fit your space |

Internal Dimensions | Adjust inside space for special storage needs |

Size | Pick from 8ft, 10ft, 20ft, 40ft, or request a custom size |

Color | Select custom colors for branding or safety |

Logo | Add your company logo for easy identification |

Packaging | Get packaging that fits your shipping or storage needs |

Graphic Customization | Add graphics for industry or safety requirements |

Usage | Design for energy storage, solar panels, generators, or other equipment |

Certification | All containers are ISO 9001 certified |

You can also ask for special features. For example, you might want extra shelves, walkways, or better ventilation. Some industries need containers with more fire resistance or extra spill protection. MEOX can add these features for your project.

Real-world stories show that custom containers fix many problems. For example, a chemical plant in Australia needed containers for both liquid and solid waste. They worked with MEOX to design units with two compartments and more ventilation. This helped them follow new 2025 rules and avoid big fines.

If you have problems after buying, like broken seals or locks, you can call the support team. They give quick help, like sending new parts or showing you how to fix things. This keeps your work going without delays.

Note: Customization helps you keep up with new trends in hazardous waste management solutions. You can change fast to meet new rules or project needs.

MEOX keeps leading with new ideas. The company updates its designs to match the latest trends and rules. You get containers that are safe, flexible, and ready for the future of hazardous waste management.

Market Shifts and Industry Solutions

Regional and Sector Demands

The hazardous waste containers market is changing quickly in 2025. Different places have their own needs and rules. North America is ahead with new packaging and RFID tracking. Europe cares about strict rules and packaging you can recycle. Asia-Pacific is growing fastest because of more factories and new laws. Japan and South Korea want advanced, safe, and smart hazardous waste containers market products.

Here is a table that shows how the hazardous waste containers market is different in each region:

Region | Demand Trends in 2025 | Key Focus Areas and Innovations |

|---|---|---|

North America | High demand for next-gen packaging, RFID tracking, fire-resistant materials | Leak-resistant, tamper-proof, e-commerce logistics |

Europe | Strict rules, focus on sustainable and recyclable packaging | Bio-compliant, smart labels, carbon footprint reduction |

Asia-Pacific | Fastest growth, driven by industrial production and compliance | Cost-effective, high-strength, impact-resistant materials |

Japan | Growth in pharma, electronics, specialty chemicals | Nanotech, AI testing, flame-retardant, blockchain traceability |

South Korea | Driven by trade and strict environmental rules | Leak-proof, flame-retardant, GPS tracking, IoT, RFID |

The hazardous waste containers market faces big changes. There is more competition and new technology. Companies use AI, IoT, and blockchain to track waste and follow rules. Some places have very strict rules, but others change slowly. This makes the hazardous waste containers market hard to understand. You need to know local laws and new technology.

Different jobs need different hazardous waste containers. For example:

DOT and UN rules set tough design standards for hazardous waste containers market products.

Chemical storage needs special materials like HDPE or stainless steel.

Radioactive waste needs strong, tested containers.

Labels must follow ANSI, ISO, and GHS standards.

You must check and fix containers often.

Storage rules need extra protection and safe separation.

Tip: Always check local rules before picking hazardous waste containers market products. This helps you avoid fines and keeps your team safe.

Special Equipment Solutions by MEOX

You need flexible hazardous waste containment solutions for many industries. Special equipment containers help move and store big or sensitive things. For example, you might need a container lab, a waste burner, or a mobile generator room. These solutions work well for the hazardous waste containers market in faraway or changing places.

Special equipment containers fix real problems. You can move them easily, set them up fast, and change them for your project. If you work in mining, healthcare, or energy, you need containers that handle tough jobs. The hazardous waste containers industry now has better coatings, airtight welding, and smart sensors.

After you buy, you might have problems like broken seals or locks. Good after-sales support is important. You get help with repairs, spare parts, and advice. This keeps your hazardous waste containers market work running well.

The hazardous waste containers industry keeps growing with new ideas. You see more digital tools, better safety, and greener designs. You can pick solutions that fit your needs and follow strict rules. The hazardous waste containers market will keep changing, so you must stay ready and learn new things.

The hazardous waste containers market is changing quickly. New designs help you save money and cut greenhouse gases by half. Now, you can find safer and cleaner ways to store waste. These containers are bigger and easier to track. They also keep your team safer. It is important to keep learning as the market grows.

Waste is processed in a cleaner way

Handling is faster and rules are easier to follow

There is less chance of pollution

If you use new ideas and act early, you get more benefits in the hazardous waste containers market.

FAQ

What should you do if your hazardous waste storage container leaks?

First, stop using the leaking container right away. Move the hazardous waste into a safe container. Call your supplier to fix or replace the broken one. Always wear protective gear to stay safe.

How often should you inspect hazardous waste storage containers?

Check your hazardous waste storage containers once every week. Look for any cracks, leaks, or rust on them. Write down what you find each time you check.

What after-sales support can you expect for hazardous waste storage containers?

You can get help with spare parts and repairs. Suppliers also give advice if you have problems. Many will answer quickly if you need urgent help. This support helps keep your work safe and running well.