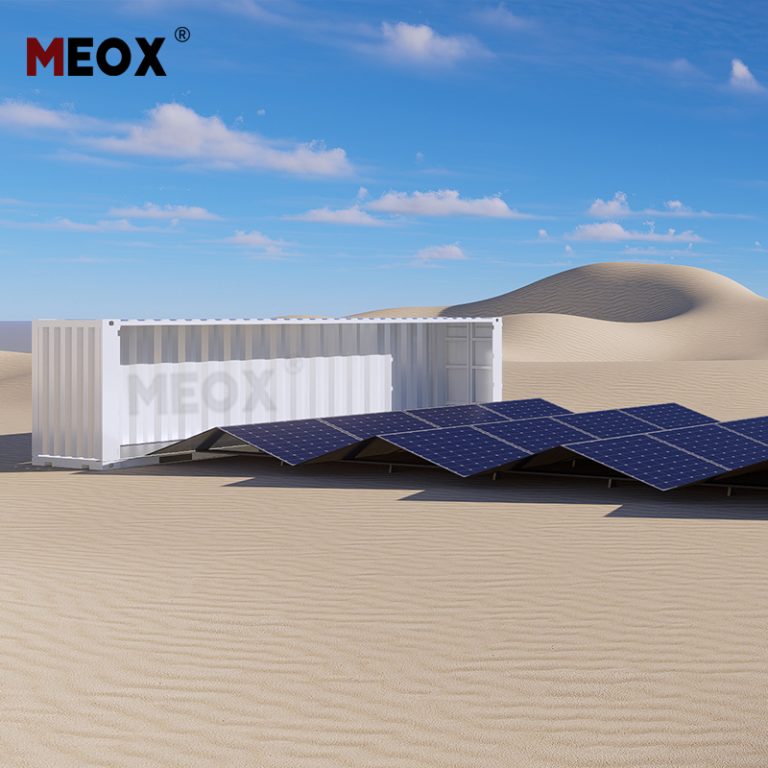

A battery energy storage container operates in diverse, often harsh environments—from coastal areas with salt spray to industrial zones with chemical fumes—making corrosion resistance a make-or-break factor for its lifespan and performance. Whether it’s a standalone battery energy storage container or an integrated container energy storage system, protecting internal batteries and electrical components from rust and degradation is critical. Suzhou Zhongnan Intelligent Equipment Co., Ltd., a leading manufacturer of special and standard containers, specializes in designing corrosion-resistant container battery energy storage solutions. With professional design teams and complete manufacturing equipment, they crafted a 40FT battery energy storage container for SEGL Energy—featuring SPA-H roof panels and hot-dip galvanized parts—that sets a benchmark for durability. As a trusted partner for wholesalers, they prioritize corrosion protection that aligns with long-term energy storage needs. This article explores the key corrosion-resistant features of battery energy storage container models, guiding wholesalers to deliver reliable solutions to clients.

Corrosion-Resistant Materials for Battery Energy Storage Container

- SPA-H Steel for Container Battery Energy Storage: The roof of a battery energy storage container—like the 40FT model Suzhou Zhongnan built for SEGL Energy—uses SPA-H steel panels. This weather-resistant steel forms a dense oxide layer when exposed to air, preventing rust even in humid or salty environments. The panels are auto-welded into a seamless roof, eliminating gaps where moisture could seep in. Wholesalers can note that SPA-H steel’s durability reduces maintenance costs, making it a top choice for container battery energy storage units in outdoor settings.

- Hot-Dip Galvanization for Container Energy Storage System: Critical components of a container energy storage system—such as locking rod assemblies (gear cams, lock tubes, handle hubs)—undergo hot-dip galvanization to a thickness of 75 microns. This process coats parts in a layer of zinc, which acts as a sacrificial anode, corroding before the underlying steel. For battery energy storage container models in coastal areas, this galvanization ensures locking systems and floor cross members remain functional for decades, avoiding rust-related jams or structural weakening.

- Rock Wool Insulation for Battery Energy Storage Container: A battery energy storage container’s interior uses rock wool insulation panels (inserted to form a whole roof lining) that resist moisture absorption. Unlike traditional insulation, rock wool doesn’t trap water—preventing mold growth and corrosion of internal steel surfaces. This is especially important for container energy storage system units, where dampness could damage sensitive battery cells or electrical wiring. Suzhou Zhongnan’s insulation design also enhances thermal efficiency, keeping batteries at optimal temperatures.

Structural Design for Corrosion Protection in Container Energy Storage System

- Seamless Welding for Battery Energy Storage Container: Battery energy storage container roofs and floors feature seamless auto-welding—like the SPA-H roof panels welded to top side rails in the SEGL Energy model. This eliminates overlapping edges or gaps where water, salt, or debris could accumulate, reducing corrosion risk. For container battery energy storage units with foldable insulation side doors, Suzhou Zhongnan ensures door frames are welded directly to the container’s steel structure, creating a tight seal that blocks moisture ingress.

- Drainage Systems for Container Battery Energy Storage: A container battery energy storage unit’s roof and floor include sloped designs and hidden drainage channels to redirect rainwater or melting snow away from the structure. The 40FT model for SEGL Energy, for example, has a subtly sloped roof that guides water to perimeter drains, preventing pooling (a major cause of roof corrosion). Wholesalers can emphasize this design to clients in rainy or snowy regions, as it extends the container’s lifespan by avoiding water-related damage.

- Corrosion-Resistant Seals for Container Energy Storage System: Container energy storage system doors and access panels use EPDM rubber seals—resistant to UV rays, salt, and chemicals—to block moisture and dust. These seals are compression-fitted to door frames, maintaining their elasticity even in extreme temperatures (from -40°C to 80°C). For battery energy storage container units in industrial zones, these seals also prevent chemical fumes from entering, protecting both the structure and internal components.

Corrosion Resistance for Different Container Battery Energy Storage Environments

| Environment | Corrosion Threat | Best Protection Feature |

| Coastal Areas | Salt spray and high humidity. | Hot-dip galvanized parts + SPA-H steel roof for battery energy storage container. |

| Industrial Zones | Chemical fumes and dust. | EPDM seals + rock wool insulation for container energy storage system. |

| Rainy/Snowy Regions | Standing water and freeze-thaw cycles. | Sloped roof + drainage channels for container battery energy storage. |

| Arid Regions | UV radiation and sand abrasion. | UV-resistant paint + durable steel panels for battery energy storage container. |

This table helps wholesalers match corrosion protection features to battery energy storage container use cases, ensuring clients get tailored durability.

Custom Corrosion Solutions for Battery Energy Storage Container

- Project-Specific Material Selection: Suzhou Zhongnan customizes material choices for battery energy storage container projects—like the SEGL Energy 40FT unit—based on client environments. For example, container energy storage system units in desert regions get extra UV-resistant paint, while those in coastal areas use thicker galvanization (75+ microns). Wholesalers can offer this customization as a value-add, showing clients the container is engineered for their unique corrosion risks.

- Pre-Testing for Corrosion Resistance: Before delivery, container battery energy storage units undergo salt spray testing (per ISO 9227 standards) to validate corrosion resistance. The 40FT model for SEGL Energy, for instance, passed 500 hours of salt spray testing—confirming its ability to withstand coastal conditions. Suzhou Zhongnan provides test reports to wholesalers, helping clients demonstrate compliance with industry standards and secure project approvals.

- Maintenance-Friendly Design: Battery energy storage container models are designed for easy corrosion checks—exposed parts (like locking rods) are accessible for visual inspections, and insulation panels can be removed to check internal steel surfaces. Suzhou Zhongnan includes maintenance guides for wholesalers, outlining simple steps (e.g., cleaning galvanized parts annually) to extend corrosion protection, reducing client downtime.

Battery Energy Storage Container FAQS

How Long Does Corrosion Protection Last in a Battery Energy Storage Container?

A well-designed battery energy storage container (like the SEGL Energy 40FT model) maintains corrosion protection for 15–20 years. SPA-H steel and 75-micron galvanization resist rust for decades, while regular maintenance (e.g., sealing checks) can extend this lifespan to 25+ years—ideal for long-term energy storage projects.

Can an Existing Container Energy Storage System Be Retroactively Corrosion-Protected?

Yes, existing container energy storage system units can be retrofitted with corrosion solutions—like adding galvanized covers to exposed parts or applying UV-resistant paint. Suzhou Zhongnan’s team assesses the unit’s current condition first, then recommends targeted upgrades, allowing wholesalers to serve clients with existing fleets.

Does Corrosion Protection Add Weight to a Container Battery Energy Storage Unit?

Corrosion protection adds minimal weight—hot-dip galvanization adds ~5–10kg to a 40FT container battery energy storage unit, and SPA-H steel is only slightly heavier than standard steel. This extra weight doesn’t impact transportation or installation, making it a negligible trade-off for durability.

Are Corrosion-Resistant Battery Energy Storage Container Models More Expensive?

Initial costs for corrosion-resistant battery energy storage container models are 10–15% higher than standard units, but they save money long-term by reducing maintenance and replacement costs. For example, the SEGL Energy unit’s SPA-H roof avoids costly roof repairs every 5–7 years, making it cost-effective over its lifespan.

Where Can Wholesalers Source Corrosion-Resistant Container Battery Energy Storage Units?

Suzhou Zhongnan Intelligent Equipment Co., Ltd. manufactures battery energy storage container and container battery energy storage units with industry-leading corrosion protection. Visit their website to explore custom solutions and partner with a trusted manufacturer for durable energy storage containers.