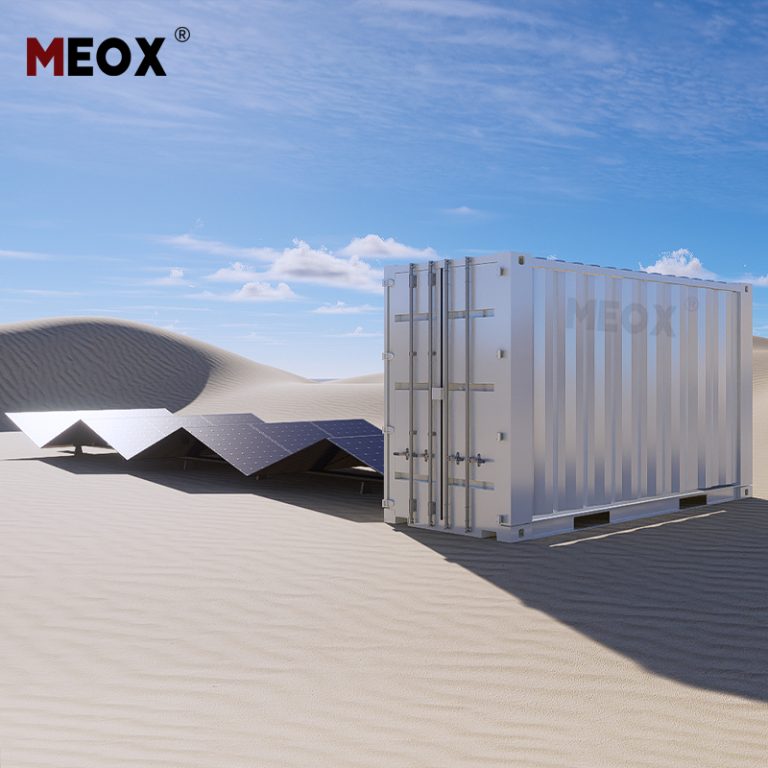

When it comes to transporting container dangerous goods, the structural integrity of hazardous material packaging is of paramount importance. Any compromise in the packaging’s structure can lead to leaks, spills, and even explosions, posing significant risks to human safety, the environment, and property. Suzhou Zhongnan Intelligent Equipment Co, Ltd., a leading manufacturing enterprise, understands these critical concerns deeply. With its complete manufacturing equipment, professional production team, and experienced design technicians, the company is dedicated to creating high – quality dangerous goods containers that ensure the utmost safety during the transportation of hazardous materials.

Factors Affecting Structural Integrity of Dangerous Goods Container

- Material Quality: The materials used in dangerous goods containers play a decisive role in their structural integrity. High – grade, durable materials such as reinforced steel or specialized polymers are commonly employed. For example, containers designed to transport corrosive container dangerous goods often feature corrosion – resistant linings to prevent degradation of the packaging structure over time. Inferior materials can weaken under the stress of transportation, increasing the risk of structural failure.

- Design and Construction: A well – thought – out design and precise construction are essential for hazardous material packaging. Containers need to be engineered to withstand various forces during transit, including impacts, vibrations, and changes in temperature and pressure. Features like reinforced corners, double – walled structures, and secure sealing mechanisms contribute to maintaining the packaging’s integrity. Poor design or shoddy construction can leave the container vulnerable to damage, compromising the safety of the container dangerous goods inside.

Testing Methods for Hazardous Material Packaging Structural Integrity

- Impact Testing: Dangerous goods containers undergo rigorous impact testing to simulate potential collisions during transportation. This involves dropping the container from specific heights or subjecting it to controlled impacts to assess how well the packaging can withstand sudden forces. By ensuring that the container maintains its structural integrity under impact, the risk of leaks or spills of container dangerous goods is significantly reduced.

- Pressure and Leak Testing: To guarantee that hazardous material packaging can contain volatile or pressurized container dangerous goods, pressure and leak testing are conducted. The container is sealed and then subjected to increased internal pressure to check for any leaks. Any signs of leakage indicate a breach in the packaging’s structural integrity, which must be addressed before the container can be used for transportation.

Maintenance Practices for Dangerous Goods Container

- Regular Inspections: Regular inspections are crucial for maintaining the structural integrity of dangerous goods containers. Trained personnel should thoroughly examine the container for signs of wear, damage, or corrosion. This includes checking for cracks in the material, loose seals, or any deformation of the structure. Early detection of issues allows for prompt repairs, preventing minor problems from escalating into major threats to the integrity of hazardous material packaging.

- Proper Cleaning and Storage: Hazardous material packaging needs to be properly cleaned after each use to remove any residual hazardous substances that could potentially corrode or damage the container. Additionally, storing the container in a suitable environment, away from extreme temperatures, moisture, and corrosive substances, helps preserve its structural integrity. For example, dangerous goods containers should be stored in well – ventilated, dry areas to prevent rust and material degradation.

| Feature | Description |

| Certification | Dangerous goods containers have CSC certification and comply with Australian export standards, ensuring safety compliance |

| Customization | A professional technical team can customize the design of dangerous goods containers to meet clients’ specific requirements |

| Function | Designed as explosion – proof boxes for safely transporting hazardous liquids and liquefied container dangerous goods |

Upgrading and Reinforcing Dangerous Goods Container

- Technological Advancements: With the continuous development of technology, new materials and construction techniques are emerging to enhance the structural integrity of dangerous goods containers. Manufacturers like Suzhou Zhongnan Intelligent Equipment Co, Ltd. stay updated with these advancements to offer hazardous material packaging that meets the highest safety standards. Upgrading containers with modern features can significantly improve their ability to protect container dangerous goods.

- Reinforcement for Specific Goods: Different container dangerous goods have unique transportation requirements. Sometimes, dangerous goods containers need to be reinforced or modified to accommodate the specific characteristics of the hazardous materials they carry. For example, containers transporting highly flammable liquids may require additional fire – resistant materials or enhanced ventilation systems to maintain structural integrity and safety.

Hazardous Material Packaging FAQS

How Often Should I Inspect a Dangerous Goods Container?

The frequency of inspecting a dangerous goods container depends on several factors, such as its usage frequency and the nature of the container dangerous goods it transports. As a general rule, containers should be inspected before each use, and a more comprehensive inspection should be carried out at least once a year. However, if the container has been involved in an accident or has been exposed to harsh conditions, it should be inspected immediately.

Can I Repair a Damaged Hazardous Material Packaging by Myself?

It is not recommended to repair a damaged hazardous material packaging by yourself. Repairs to dangerous goods containers require specialized knowledge and skills to ensure that the structural integrity is restored properly. Improper repairs can lead to further damage and pose significant safety risks. Always consult a professional, such as the experts at Suzhou Zhongnan Intelligent Equipment Co, Ltd., for any repair work on hazardous material packaging.

What Are the Consequences of Using a Dangerous Goods Container with Compromised Structural Integrity?

Using a dangerous goods container with compromised structural integrity can have severe consequences. It can lead to the leakage or spillage of container dangerous goods, causing environmental pollution, property damage, and endangering human lives. Additionally, it can result in legal liabilities, including fines and lawsuits, and damage to the reputation of the company responsible for the transportation.

How Do I Know If a Hazardous Material Packaging Meets the Required Standards?

A reliable way to determine if hazardous material packaging meets the required standards is to check for certifications. For example, dangerous goods containers with CSC certification and compliance with Australian export standards, like those provided by Suzhou Zhongnan Intelligent Equipment Co, Ltd., have undergone strict testing and meet the necessary safety requirements. You can also request documentation from the manufacturer detailing the testing and compliance of the packaging.

Where Can I Purchase High – Quality Dangerous Goods Containers?

For high – quality dangerous goods containers that ensure the structural integrity of hazardous material packaging, visit the official website of Suzhou Zhongnan Intelligent Equipment Co, Ltd. With their commitment to quality, advanced manufacturing capabilities, and professional services, they offer a wide range of reliable dangerous goods containers. Explore their products today and ensure the safe transportation of your container dangerous goods!

Ready to prioritize the safety of transporting container dangerous goods? Visit the https://zn-meox.com/ of Suzhou Zhongnan Intelligent Equipment Co, Ltd. now. Our top – notch dangerous goods containers, with unwavering attention to the structural integrity of hazardous material packaging, are your best choice for secure transportation. Don’t take risks with safety – explore our offerings and place your order today!