The safe and compliant transport and storage of hazardous materials demand specialized solutions engineered for maximum security and reliability. This critical need is met by a specialized sector of the industry focused on designing and producing containers that adhere to stringent international regulations. Navigating this market requires understanding the roles of a container company, identifying leading container manufacturers, and selecting from reputable container suppliers to source these vital products. This article provides an overview of this highly specialized field, highlighting key considerations for procuring hazardous goods containers.

Selecting a proficient container company is the first step toward compliance and safety

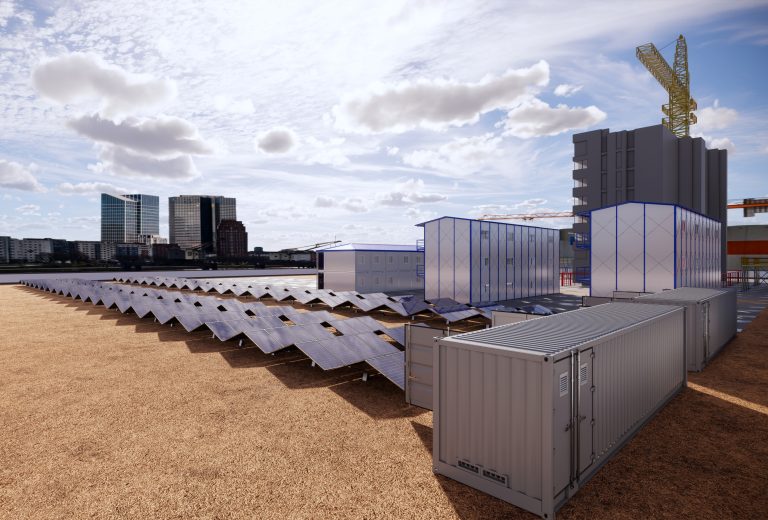

A container company involved in the hazardous goods sector offers more than just products; it provides integrated solutions that encompass design, certification, and logistical support. The role of such a company is crucial in ensuring that all aspects of handling dangerous goods are addressed, from initial manufacturing to final delivery and deployment.

• Comprehensive Service Offerings: A full-service container company does not merely act as a middleman; it often manages the entire project lifecycle. This includes conducting initial risk assessments, designing custom solutions to meet specific hazard classifications (such as those for chemicals, flammables, or radioactive materials), ensuring compliance with standards like IMDG, ADR, and IMO, and providing ongoing maintenance and recertification services to keep units in compliance throughout their operational life.

• Engineering and Design Expertise: The backbone of a reputable container company is its engineering capability. This involves utilizing advanced materials like corten steel, implementing double-wall construction for critical containment, designing integral spill containment sumps, and incorporating features such as explosion-proof ventilation, advanced fire suppression systems, and secure, tamper-proof locking mechanisms. This expertise ensures the container is fit for its intended purpose.

• Global Logistics and Support: The journey of a hazardous container from factory to site is complex. An experienced container company manages this intricate logistics chain, handling specialized transportation, customs clearance for regulated goods, and on-site installation or commissioning. They act as a single point of contact, simplifying the process for the client and ensuring that all container suppliers in the chain are vetted and reliable.

The role of specialized container manufacturers is to transform standards into secure products

Container manufacturers are the entities that physically build the containers, turning engineering designs into tangible, high-integrity assets. They possess the facilities, craftsmanship, and quality control processes necessary to fabricate containers that can withstand extreme conditions and contain hazards effectively.

• Certification and Quality Assurance Processes: Reputable container manufacturers operate under rigorous quality management systems (e.g., ISO 9001) and build to recognized international standards. Their processes include meticulous material traceability, certified welding procedures performed by qualified welders, non-destructive testing (NDT) like X-ray or ultrasonic inspection of critical welds, and final inspection and approval by certified third-party bodies to issue necessary compliance certificates.

• Customization and Fabrication Capabilities: While standard models exist, the true value of leading container manufacturers lies in their ability to customize. They work with clients to modify designs for specific chemicals, create compartments for mixed classes of hazardous goods, integrate internal shelving and restraint systems, and install proprietary safety and monitoring equipment. Their workshops are equipped with heavy machinery for cutting, bending, and assembling thick-grade steel.

• Focus on Research and Development: Top-tier container manufacturers invest continuously in R&D to improve safety and functionality. This includes developing new coating systems for enhanced corrosion resistance, testing new fire-retardant insulation materials, incorporating IoT sensors for real-time tracking of internal conditions (temperature, pressure, leaks), and refining designs to maximize payload capacity while reducing tare weight.

Connecting clients with quality products is the core function of container suppliers

Container suppliers are the vital link between the manufacturers and the end-users. They curate product offerings, manage inventory, and provide the market access necessary for clients to find the exact container solutions they need, whether they are buying, leasing, or renting.

• Diverse Inventory and Product Sourcing: A major container suppliers network is their greatest asset. They maintain relationships with multiple container manufacturers to offer a wide range of both new and certified used hazardous goods containers. This allows them to provide options for different budgets and immediate availability for standard units, while also facilitating the order of custom-built units from their manufacturing partners.

• Value-Added Services: Beyond simple sales, distinguished container suppliers offer services that add significant value. These include leasing arrangements, long-term rental options, full refurbishment and recertification of used containers to “as-new” standards, on-site repairs, and comprehensive parts and components support for maintenance, ensuring minimal downtime for their clients.

• Market Knowledge and Regulatory Guidance: Experienced container suppliers serve as knowledgeable advisors. They stay current with evolving international and local transportation and storage regulations. They can guide a client to the correct container type and class for their specific material, advise on labeling and placarding requirements, and help navigate the complex documentation needed for compliance, effectively de-risking the procurement process for the buyer.

Container Company FAQs

Q: What services does a typical Container Company offer beyond just selling containers?

A: A standard Container Company often provides end-to-end services: container modification (adding doors/windows for offices/homes), repair/maintenance (fixing dents/rust), cleaning/sanitization (for food/pharma use), and logistics coordination (arranging delivery via truck/ship). Many also offer leasing (short/long-term) and storage solutions, plus customization like insulation (for refrigerated needs) or security features (locks/alarm systems), catering to both commercial (shipping, construction) and residential (container homes) clients.

Q: How do I choose reliable Container Manufacturers for bulk orders?

A: When selecting Container Manufacturers for bulk orders, prioritize those with ISO certifications (e.g., ISO 1496-1 for shipping containers) to ensure quality. Check their production capacity (can they meet your timeline?) and material standards (e.g., corrosion-resistant steel for marine use). Ask for sample containers or client references, and confirm they offer post-sales support (warranty for defects). Avoid manufacturers with no clear quality control processes or vague delivery timelines.

Q: What’s the difference between Container Suppliers and a Container Company?

A: Container Suppliers typically focus on distributing pre-made containers (from manufacturers) to clients, often with limited add-on services. A Container Company, by contrast, offers a broader scope: it may partner with manufacturers, but also provides modification, repair, leasing, and logistics—acting as a one-stop shop. For example, a supplier might only sell a standard container, while a company can turn that container into a portable office and deliver it to your site.

Q: Can Container Manufacturers create custom containers for specialized needs (e.g., hazardous goods)?

A: Yes, most reputable Container Manufacturers design custom containers for specialized use. For hazardous goods, they build units with leak-proof seals, fire-resistant materials, and ventilation systems (per UN/IMDG codes). For food/pharma, they make insulated, sanitized containers that meet FDA standards. They can also adjust size (non-standard lengths) or add features (tank liners for liquids), but custom orders usually require longer lead times and adherence to industry regulations.

Q: What factors affect pricing when buying from Container Suppliers?

A: Pricing from Container Suppliers depends on: container type (new vs. used—used costs 30-50% less), size (20ft vs. 40ft), condition (cargo-worthy vs. as-is), and added features (insulation, refrigeration). Logistics (delivery distance, shipping method) also impact cost, as does order volume (bulk orders get discounts). For example, a new 40ft refrigerated container will cost more than a used 20ft dry container, plus extra for long-distance delivery.