Many laboratories and manufacturing companies inevitably require or produce various substances during their course of production. Some of the substances used in these institutions are so dangerous that they need proper storage and shipping. Today, the significance of safety and compliance cannot be overstated, especially in industries involved in the transportation and storage of materials that are hazardous. Here, we get introduced to the term “Hazardous Container”.

Fig.1: A high-quality hazardous container

What Are Hazardous Containers?

The term “hazardous container” indicates containers that are particularly designed to safely store, transport, and handle materials that can pose a threat to health, safety, or the environment. In the container house industry, hazardous containers are essential for the secure storage and transport of dangerous materials to protect individuals and properties from possible harm. These hazardous containers are being built to comply with rigorous regulatory standards, intended to reduce the chances of leaks, spills, or accidents. With my years of experience in ZN MEOX, I will outline the definition of the term and the applicable rules and regulations.

Fig. 2: Inside view of a hazardous shipping container

Hazardous containers, also termed as hazardous shipping containers or simply DG (Dangerous Goods), are specially designed containers which are used for safely storing, transporting, disposing and handling dangerous goods that can bring significant risks to health, safety and the environment. Flammable chemicals, for instance, need utmost care and a specialized container for transportation from one place to another with a view to avoiding the potential harm arising from mismanagement. Industries related to healthcare, manufacturing, energy or even construction sites may use hazardous containers as most of their materials are hazardous-prone. These containers are included with spill containment, ventilation and secure locking mechanisms that prevent leaks and exposure.

Fig. 3: Some hazardous containers are displayed

Hazardous containers are used for transporting dangerous goods primarily and storing them temporarily in liquid, gas and solid forms. The typical dimension of these hazardous containers is 20 feet and generally comes with an end door and one full-sided door for convenient access and the movement of the materials. A 20-foot dangerous goods container is capable of fitting two 9-foot dry boxes.

Interestingly, hazardous materials are widely termed as “Hazmat”, which sounds like Arabic, right?

Advantages of Hazardous Containers

Dangerous goods need careful consideration to ensure efficiency, safety and regulatory compliance. In this blog, I aim to present 5 reasons for utilizing a hazardous container in your workplace if your objective is to minimize the risks like human injury, fire hazards or environmental contamination.

- Portability: Being a fully relocatable storage container, hazardous containers provide flexibility. Provided that your storage needs changing the location or you need to move your operation to a new place, your storage can easily move with you. These containers have some features, such as forklift channels, lifting lugs (allowing you to use a crane to lift onto a truck for transport) and locating plates that allow for easy transportation. The industry that frequently shifts locations such as mining or oil and gas, is highly benefited by this feature.

- Fireproof Design: When you need to transport flammable chemicals in shipping containers, fireproof designing features come as the saviour.

The hazardous containers are made from heavy-duty, non-combustible steel and double-door fire-rated technology that provides an added layer of protection against fires.

Fig. 4: Rear view of a hazardous container

- Cost-effective Storage: To invest in high-quality and durable hazardous shipping containers may look expensive. However, if you think of it as a preliminary investment and for long-term savings, then it is substantial. An effective hazardous container can lead to significant cost savings over time by reducing damage rates, minimizing the risk of regulatory fines and decreasing the need for repairs and replacements. An ideal container has a warranty period of 20 years; thus, you can avoid a potential moderate spill incident, sidestep the regulatory scrutiny that might otherwise result in fines for non-compliance and pay lower insurance premiums over the long lifespan of the container. A lot of money will be saved.

- Durability: Considering the ideal container for your DG, you need to make sure how durable the container is. As the hazardous containers are constructed for the outdoor environment (in most cases), they are corrosion-resistant coated. Renowned brands, like ZN MEOX, use high-quality C3 paint for protection, and the coating is 220 microns thick. The paint prevents corrosion and increases the durability of the containers for years.

- Fulfilling Compliance Requirements: Most of the hazardous containers are designed and constructed to meet the requirements of the relevant Australian Standard for storing hazardous materials. Each category of hazardous materials is governed by a specific standard that specifies all the attributes required for a container to be considered compliant. Examples can be given as spill containment capacity, ventilation, construction materials, door closing mechanisms and security features.

Hazardous Container Regulations Governing Hazardous Containers

The secure management, storage and transportation of hazardous materials is subject to a comprehensive system of regulations. The provisions of these regulations are designed to protect the workers, public health and the environment from the potential dangers posed by the dangerous goods. These regulations vary from location to location. However, the objective is the same: to ensure the protected containment of hazardous materials.

- Overview of Global and Local Regulations: Depending on the nature of the goods, there are some encompassed local and international rules for the standard maintenance of the hazardous containers. Below are some most recognized bodies and standards that usually govern hazardous container use:

- EPA (Environmental Protection Agency): An USA based agency that works as the central body to regulate hazardous materials under the RCRA Act (Resource Conservation and Recovery Act).

- DOT (Department of Transportation): The DOT also enforces regulations governing the transportation of hazardous materials in the USA. The Hazardous Materials Regulations (HMR) is issued by the DOT.

- UN Certification: UN Certification for hazardous materials transport ensures that packaging is strictly tested and certified to meet international safety standards for transporting dangerous goods.

- IMDG (International Maritime Dangerous Goods) Code: The IMDG Code provides an internationally recognized framework to transport hazardous goods by sea. Packaging requirements, labelling standards, and documentation are their main issues of concern.

- OSHA (Occupational Safety and Health Administration): OSHA regulations mandate that businesses must inform workers regarding the hazardous materials they may encounter, which includes guidelines for proper handling and storage of containers.

- European Union Regulations: the Classification, Labelling, and Packaging (CLP) Regulation incorporated by the EU ensures that hazardous materials are clearly labelled and handled with strict safety protocols.

- IATA (International Air Transport Association): They have some specific rules and regulations related to the air shipment of hazardous goods.

Among these bodies, DOT and EPA’s rules and regulations are well recognized all over the world, and they establish a “cradle-to-grave” system, which includes the container from the time the dangerous goods are placed inside until it undergoes treatment, storage or disposal.

Here is a breakdown of the rules and regulations:

- DOT: The Department of Transportation’s Hazardous Materials Regulations (HMR), found in Title 49 of the Code of Federal Regulations (49 CFR), dictate how hazardous materials must be packaged and shipped.

- EPA: The EPA’s Resource Conservation and Recovery Act (RCRA) regulations, found in Title 40 of the Code of Federal Regulations (40 CFR), govern the management of hazardous waste, particularly while it is being accumulated (stored) on site by the generator.

As per DOT, hazardous materials are classified based on their properties, potential risks, and handling requirements. For details, visit here.

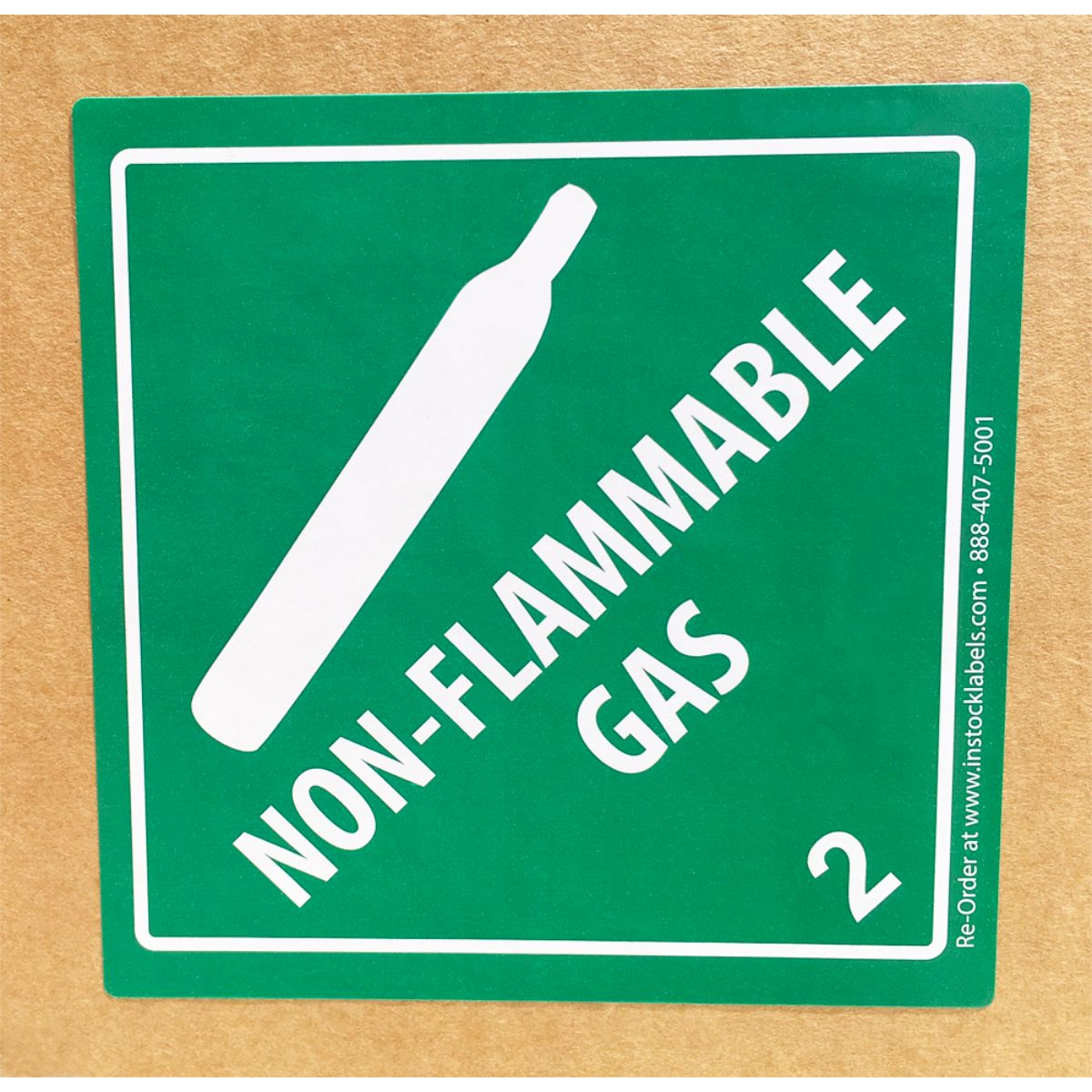

| DOT Hazmat Classes | Category | Example | Label |

| Class 1 | Explosives | Ammunition |  |

| Class 2 | Gases | Propane Tanks |  |

| Class 3 | Flammable Liquids | Gasoline |  |

| Class 4 | Flammable Solids | Matches |  |

| Class 5 | Oxidizers | Hydrogen Peroxides |  |

Table 1: Hazard Classification

These rules are detailed and specifically applicable to the material, quantity, and transport method involved. The shipper bears the ultimate responsibility for ensuring complete adherence to both the EPA (storage) and DOT (transport).

Some Real-life Examples

When some of our colleagues were working in a factory located in South Africa, they noticed that the local regulatory authority was very much concerned about the adherence to the hazardous goods management system. They visited the site several of times to check whether we were being compliant or not. The Australian seaport Melbourne was not allowing a hazardous container from another company to enter into the country as the container did not pass the standards mentioned in the EPA. I suggested my company, ZN MEOX, to strictly follow the rules mentioned in the EPA and the Australian Export Standards. I have also heard that one of the peer hazardous container manufacturing companies could not pass their containers in Singapore as the 2.5-year leakproofness test certificate had expired. Today, we have the Australian Export Standard Certificate, CSC certification, and ISO 16106:2020 Certification to give all-in-one services to our customers.

Conclusion

The smart buyers must prioritize regulatory-compliant, compatible, and correctly labelled hazardous containers to ensure safe transport, legal compliance, and uninterrupted operations. The contemporary use of hazardous containers is becoming more widespread, popular, and a pragmatic solutions for dangerous goods management. In the coming days, there will be more standards and norms regarding the maintenance of dangerous goods. We are methodically trying our best to improve the standards of these containers and our engineers are designing new ideas highlighting the feedback from our customers (If Any). Only a perfect hazardous container can not only help you assure a safe shipping, but also protect personnel, the environment, and the company from catastrophic fines and incidents

Hazardous Container FAQS

Question: What materials require hazardous containers?

Answer: Materials that are flammable, explosive, corrosive, toxic, or reactive usually require hazardous containers

Question: What regulations govern hazardous containers?

Answer: Hazardous containers must comply with various global and local regulations, like EPA, DOT, OSHA, IMDG, etc.

Question: Can hazardous containers be used for long-term storage?

Answer: Yes, hazardous containers are designed for both short-term and long-term storage of hazardous materials.

Question: How do hazardous containers differ from regular containers?

Answer: Unlike regular containers, they have specialized features like flame-retardant materials, spill containment systems, special Ventilation systems, secure locking mechanisms, etc.

The article portrays a brief discussion on the definitions and regulatory requirements of Hazardous Containers in a detailed way, which will unquestionably provide helpful information for those considering the purchase of a hazardous shipping container. Furthermore, to get comprehensive insights and to know other related things, please visit our website thoroughly and contact our customer care. We have 30+ distributors all over the world available to support you locally.

(The author has been working in MEOX as the Overseas Business Development Manager for the last couple of years. He has experience dealing with international projects in Asia, Africa and some South American countries).