A Dangerous Goods Container is a specially designed shipping container. It ensures the safety of hazardous materials during transport and short-term storage in liquid, solid, or gaseous form. These containers provide secure, organized, and compliant storage through which the business entities can reduce the time spent managing hazardous materials and ensure smooth workflows.

Containers are the backbone of world trade. Still, they are not all similar. In the case of the transport of hazardous materials, we cannot use ordinary boxes. We require special engineering and strict certifications. Shipping dangerous goods is an operation that cannot afford to have even the smallest mistake. Just one error might result in environmental damage, large fines, or even accidents with fatalities. That is the reason why the specialized Dangerous Goods Container is not merely a choice. It is an absolute necessity for worldwide trading. Safety is not merely a preference; it is the non-negotiable prerequisite for global hazardous materials trade.

Fig. 1: A Dangerous Goods Container is prepared for shipment

As a Project Manager at ZN MEOX for the past seven years, I have gained extensive experience in hazardous materials transportation. I am familiar with the intricacies involved in the transportation of hazardous materials. Actually, over this period of my involvement, I have experienced numerous companies finding it tough to meet the requirements and guidelines.

I have the knowledge and hands-on experience to share with you, which will help you understand the essential compliance requirements and the safety features of the Dangerous Goods Container.

What is a Dangerous Goods Container? Decoding the Terminology

Melissa Hampton, an Australian Dangerous Goods storage consultant, defines a dangerous goods container as “a portable chemical storage container that’s designed to house a specific class of dangerous goods.”

A conventional shipping container is essentially a metal box designed for general use, whereas a Dangerous Goods Container is engineered specifically to handle hazardous materials. It is a precisely designed system. Such systems necessitate certain changes. They have to handle chemical and material hazards safely. The main feature is always supplementary containment. Usually, it means a leak-tight sump that is part of the floor. Also, correct ventilation is very important. It serves to protect the staff from the inhalation of toxic gases.

In brief, DG containers are created to be a safe storage and transportation for flammable liquids, liquefied gases, and explosive materials. Such units have to be in line with global standards. At ZN MEOX, we make sure our containers are certified by CSC. They are also up to the tough export standards of various countries. The compliance of such a region as Australia is a part of this.

Defining Dangerous Goods (Hazardous Materials or Hazmat)

Dangerous goods are such kind of materials that can cause harm to human health, safety, or the natural environment. These are various types of substances like liquids, solids, and gases. They can be corrosive, inflammable, or explosive. So, the design of the container for Dangerous Goods must be such that it lessens or gets rid of these dangers.

Regulatory Standards and Certifications for Dangerous Goods Containers

Dangerous Goods Containers must comply with several key regulations to ensure safety and legal compliance during transport and storage:

IMDG Code (International Maritime Dangerous Goods Code)

The IMDG Code from the International Maritime Organization (IMO) specifies the safety measures to be followed in the transportation of hazardous materials by sea. For the most recent changes, see IMO Resolution MSC.474(102) that provides details for the updated standards for container design and testing. The most recent mandatory version is IMDG Code, Amendment 41-22.

49 CFR (Code of Federal Regulations, Title 49)

Wherever in the United States hazardous materials are being transported, 49 CFR is the main regulating authority, overseen by the Department of Transportation (DOT). Part 178 gives detailed directions for the making of containers so that they can be safe with the hazardous substances and strong enough for transport (as described in 49 CFR Part 178, current as of 2025).

UN Dangerous Goods List

The UN Dangerous Goods List classifies hazardous materials according to their risk and thus requires different classes to have various features in their containers. The provisions (19th Revised Edition) are there to take precautionary measures in the packaging and containment of the goods during the transportation period, the case of which is mainly a Class 3 (Flammable Liquids) that is volatile.

IMO Tank Container Specifications

IMO tank containers should, in my opinion, conform to ISO 1496-3 in terms of their design and safety features. The newest IMO Resolution MSC.150(77) details the requirements for containers used for the transport of liquids and gases. It also specifies the features of pressure relief valves and safety seals.

The ISO Standard and Specialized Features

Every high-quality Dangerous Goods container is equipped with various safety features that are essential for user protection. Basically, the material of the container is what I most often point out. In terms of paint, my suggestion would be a C3 grade standard system, which is made up of 220 microns of thickness. The user may upgrade this to the C5 coatings if he/she is planning to use it in a very harsh environment. The final product will have excellent protection against rust and abrasion.

It is essential to include safety features that ensure the container operates efficiently and safely under all conditions. The bottom of the container should definitely have a secondary containment system. This tray is designed to collect the small amounts of liquid that have leaked. Thus, it prevents pollution of the environment.

International risk managers are putting a lot of emphasis on this design feature above everything else. The TT Club (a mutual insurer for the intermodal transport industry), in its various reports on the top causes of environmental spillage at port transfers, cites the failure of primary containment – and the absence of a working, compliant secondary sump – as the most frequent reason leading to hefty fines for spillage of the environment. Hence, the secondary containment system goes beyond being just a feature; it is an essential regulatory safety net.

I additionally suggest that there be an aluminium grating inside the container. This is to prevent the cargo from moving, and thus it will not cause the release of the liquid. In addition, the doors must be designed with safety locks. These locks have to be able to open from the inside. Hence, it prevents the accidental entrapment of the operators. Correct ventilation is essential. It should be ensured that there are large vents and exhaust louvers on each door. That is how good air circulation is ensured.

Fig. 2: Inside view of a Dangerous Goods Shipping Container

Expert Opinions

“Compliance is not an abstract goal; it is a documented chain of custody. We see 80% of our major client fines stemming from simple failures to accurately link the container’s CSC plate and UN documentation to the most recent regulatory amendment.”

–Dr. Elena Vargas, Accredited IMDG/IATA/49 CFR Certified Hazmat Instructor, Global Compliance Solutions.

“As marine surveyors, our focus is on the structural certification period. A container with an expired CSC re-inspection date, even if structurally sound, is a hard fail at the port gate. That simple administrative lapse can stop a $1M shipment.”

–Kenji Tanaka, Director of Marine Cargo Surveying, Asia-Pacific Region, Shujuka Survey Inc.

“Our underwriting models show that a certified, purpose-built DG Container reduces the loss ratio by up to 30% compared to general-purpose containers modified for hazmat. It is an investment in insurable risk mitigation.”

–Jane C. Smith, Chief Underwriter, Marine Cargo Risk Division, Prime Finance Insurance Co. Ltd.

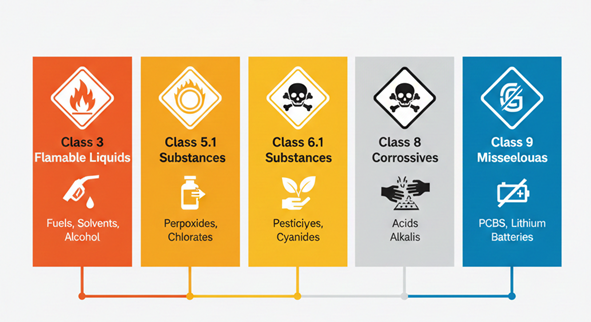

The Nine Classes: Understanding UN Number and Classification

It is of utmost importance to comprehend the 9 classes of dangerous goods according to the UN. These classes determine the exact type of container that you are allowed to use.

The whole classification operation is a matter of real expertise and very careful work.

Introducing the IMDG Portable Tank Instructions (T-Codes)

Quite a few hazardous substances have to be housed at the maximum containment level, typically in specialized ISO tank containers. These units must strictly conform to the IMDG Code Portable Tank Instructions (T-Codes), as mandated by the International Maritime Organization (IMO). These T-Codes guarantee the secure transport of the consignment by sea.

The T-Code assigned to a specific UN Number dictates the tank’s precise technical requirements, including the required shell material, Maximum Allowable Working Pressure (MAWP), and minimum shell thickness, as detailed in IMDG Code Chapter 4.2.

It is essential to understand the correct T-Code for your substance. For instance, highly volatile Class 3 Flammable Liquids often require the rigorous T11 Portable Tank Instruction, which dictates stricter pressure ratings than those assigned a lower T-Code.

There are different sizes of the Dangerous Goods Container, such as 8-foot, 10-foot, 20-foot, and 40-foot units.

The majority of Dangerous Goods classes we handle fall under specific categories:

| Class No. | Hazard Category | Description | Common Example |

| Class 3 | Flammable Liquids | Liquids that easily ignite. | Fuels, Solvents, Alcohol |

| Class 5.1 | Oxidizing Substances | Materials that release oxygen, boosting combustion. | Peroxides, Chlorates |

| Class 6.1 | Toxic Substances | Materials that cause death or serious injury. | Pesticides, Cyanides |

| Class 8 | Corrosives | Substances that damage skin, eyes, or metals. | Acids, Alkalis |

| Class 9 | Miscellaneous | Goods not covered by other classes (e.g., environmental hazards). | PCBs, Lithium Batteries |

Table 1: A Quick Guide to IMDG Dangerous Goods Classes

Specifically, the IMO tank container standards matter a lot when we talk about Class 3 liquid. They require a very detailed and accurate design. Besides that, the Dangerous Goods container has to be a safe one not only for the goods but also for the people who handle the cargo and the environment. Making the decision on which container size to use is a combination of business and safety considerations.

Here is an infographic display of the DG classes for your quick reference:

Fig. 3: Infographic display of the DG Classes

Beyond the Ocean: Navigating ADR, RID, and 49 CFR Requirements

Although the IMO tank container standards are the most important requirement for a long-haul sea transport, the road of a Dangerous Goods Container rarely starts or ends at a port. The essential first and last miles—inland transport by truck and train—are controlled by very strict regional and national laws. If you do not follow these rules, your goods can be confiscated on the spot, you will get heavy fines, and your transport will be delayed for a long time, thus all the effort made for sea compliance will be wasted.

An expert really knows that international conformity is only possible if you follow a network of interrelated rules. When purchasing or renting a container, it is important to consider the specific requirements of your shipment.

European Inland Transport

For movements within or into European nations, two primary regulations dictate road and rail compliance:

ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road): In essence, these regulations are all-inclusive for the road transport of hazardous materials, specifying the type of vehicles, the required documents, and the driver’s training. Any road transport of a DG container on European roads has to meet the packing and construction stipulations of ADR that are applicable.

RID (Regulations concerning the International Carriage of Dangerous Goods by Rail): Just like ADR, RID is about the exact specifications for the transportation of hazardous materials by rail in Europe.

North American Compliance: 49 CFR

Any cargo that is coming from, passing through, or destined for the United States must comply with the regulations set by the U.S. Department of Transportation (DOT).

49 CFR (Title 49 of the Code of Federal Regulations): This is the intricate regulatory system that specifies the rules for the transportation of hazardous materials (Hazmat) within the United States. The document basically covers everything, starting with the manufacture and the certification of the package up to the required training of Hazmat employees, shipping papers, and emergency response information.

In most cases, the North American community sets the quality standard of a container that passes the strict 49 CFR standards, as a benchmark for other qualities. While dealing with our customers, particularly the ones who have intermodal movements (sea-to-rail or sea-to-road), I prioritize units that offer dual certification for both IMO and inland transport standards, ensuring operational flexibility.

Operational Safety: Placarding, Labeling, and Cargo Segregation

A compliant Dangerous Goods Container represents only half the solution; the other half is the strict observance of operational loading and labelling instructions. These real-life details happen to be the most frequent instances of failure locations in front of port and customs officers. As a seasoned Project Manager, I can attest that forgetting these simple steps is the quickest method to get fined.

Compliance Visibility: The Non-Negotiable Rules for DG Placarding

The container alone has to be very clear that it is carrying hazardous materials to the emergency responders as well as the transport personnel all over the world. This is done through two separate, compulsory markings:

Hazard Class Diamond Placards: These are the signs that people see immediately and from which they can understand the hazard. It is necessary to put them on all four sides and usually, on both ends of the container. The color and the symbol on the placard indicate the main hazard class of the product (for instance, a red flame for Class 3 Flammable Liquids, or a corrosive symbol for Class 8).

UN Number Markings: This is a four-digit code that is placed right under the placard (or sometimes on the placard), and it refers to a specific substance (e.g., UN 1203 for Gasoline). This number is different for each chemical, and therefore, it helps the fire brigade in their rescue operation to quickly find out the exact solutions in case of a hazard.

The Golden Rule of Hazmat: Incompatible Goods and Cargo Segregation

Proper segregation might be the single most important safety step that is often overlooked in DG shipping. Some classes of dangerous goods, if mixed or stored close to each other, can react aggressively, thus causing fires, explosions, or even the release of toxic gases.

The concept is simple: Incompatible materials must be physically separated to prevent hazardous reactions.

Just take as an example, that a Class 3 Flammable Liquid should never be kept next to a Class 5.1 Oxidizing Substance. The Oxidizer (that supplies oxygen) would increase to a great extent the fire that it is already there if the Flammable Liquid were to leak.

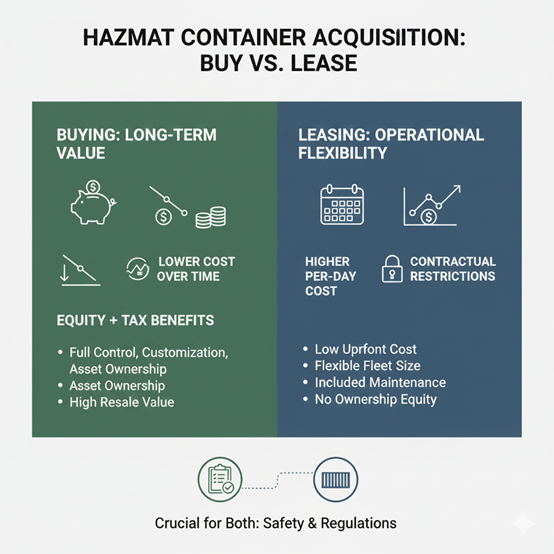

Cost & Compliance: Buying vs. Leasing a Dangerous Goods Container

The choice of purchasing or renting a Dangerous Goods Container is a significant financial decision. I always recommend thinking in terms of big and long-term strategy. Purchasing might be costly at first, but it gives you a lot of power and value in the long run. Leasing, on the other hand, is more of a short-term solution, and you cannot really plan with it.

Factors Affecting the Price of a Used Dangerous Goods Container for Sale

Based on ZN MEOX project data across 100 long-term clients, the effective Cost Per Day of container ownership over a 20-year asset life is 45% lower than the cumulative operational expense of a comparable lease model. When you buy a Dangerous Goods container, you are basically turning the cost of running your business into a company asset. The asset loses value gradually over time, allowing you to enjoy tax benefits, which is quite a financial advantage. Leasing costs, on the other hand, are ongoing. As a result of the purchase, you have total freedom regarding any changes and the maintenance condition of your unit. Such control is very important in the case of special IMO tank container specifications or peculiar storage requirements. Additionally, there is a good market for a ‘Used Dangerous Goods Container’, which means that the asset is holding quite a high residual value at the time of its resale. I find that the highest value for money is almost always realized through ownership.

| Factor | Buying (New/Used) – ADVANTAGE | Leasing – Considerations |

| Financial Impact | Builds Equity and provides tax benefits (depreciation). | Perpetual Cost (100% operational expense). |

| Customization | Complete control for specific cargo needs and longevity. | Highly restricted; requires landlord permission. |

| Long-Term Cost | Lower effective cost per day over the 20–30-year lifespan. | Total payments often exceed the purchase price. |

| Control | Total operational control over maintenance and compliance. | Dependent on the leasing company’s service schedule. |

Table 2: Cost Comparison: Buying vs. Leasing

Navigating Dangerous Goods Container Leasing Requirements

Leasing allows you to be flexible, but there are strict contracts and increased risks involved. In the case of a leased Hazmat container, the requirements for the lease usually specify very rigorous clauses for damages and early termination. The contract specifies how the maintenance is carried out and the return conditions. These conditions are usually so difficult that one cannot avoid extra charges without incurring them. While I am assisting clients to understand the complicated requirements for the leasing of a Dangerous Goods container, I remind them of the budget constraints, too. Simplifying the compliance in the long run and getting rid of the risk of these contracts, it is better to have your own container. Even if the container is not yours, you have to be sure that it complies with the Dangerous Goods container leasing requirements of the country of destination.

Fig. 4: Strategic Comparison: Key Differences Between Purchasing and Leasing a Dangerous Goods Container

For a detailed, comprehensive view of the dangerous goods container, including internal and external features, please watch the video below.

Maintaining Compliance: Your DG Container Inspection and Certification Schedule

The choice to buy a Dangerous Goods Container is essentially putting money into a long-term asset; however, the worth and lawfulness of that asset are wholly contingent on ongoing conformity. Basically, a DG container, even if it is very strong, can only be considered a safe and certified international transport unit if the safety rating is up to date.

The CSC Plate: Your Container’s Passport

All shipping containers used for international freight, even those that are carrying dangerous goods and are specially made, have a Convention for Safe Containers (CSC) Plate affixed to them. This metal plate is the official ‘passport’ that shows the container has been checked and is in compliance with safety and structural soundness. In case of the absence of a proper CSC Plate certification, the container will not be allowed to be put on a ship or railcar.

Top-classifying agencies like Bureau Veritas and Lloyd’s Register are not only concerned with the metal strength of the container; their inspectors also perform a thorough examination of the condition of the internal linings and floor sumps as a part of the compulsory 30-month re-inspection. This act serves as their endorsement that the container can be used for the transport of dangerous goods in compliance with the CSC.

Mandatory Periodic Inspection Schedule

When it comes to Dangerous Goods containers, one of the things I keep emphasizing repeatedly is the necessity of knowing the re-inspection cycle very well:

First Inspection: The very first mandatory inspection is to be carried out no later than five years from the manufacturing date.

Subsequent Inspections: From the first period onwards, re-inspections are to be done every 30 months (2.5 years).

Such a timetable is absolutely binding for containers employed in international trade. Being the owner of the asset, it is your obligation to both arrange and pass these inspections.

Real-World Experience: Case Studies in Safe Shipping

Case Study 1: Transporting Flammable Liquids for Chem-Logistics Inc.

The Challenge: In 2021, Chem-Logistics Inc. found it difficult to transport Class 3 flammable liquids from its plant in Houston, Texas, to a distribution hub in Rotterdam, Netherlands. The company was using the old equipment. The equipment was the source of frequent grief with the compliance officers during the important port inspections.

The Solution: I offered them advice and later provided a fleet of 20-foot Dangerous Goods Container units from ZN MEOX. Each unit was equipped with upgraded insulation. This facilitated the keeping of standard internal temperatures for the whole export routes from Europe to America. The containers were equipped with the patented ZN MEOX drip-tray system.

Testimonial: Linda Adams, the Operations Director at Chem-Logistics, stated: “We were requiring containers that were capable of adjusting to varying regulations, both for road and sea. The ZN MEOX team was very helpful in that regard. Their technical expertise was of the highest level. From the moment we made the change, we have not had a single compliance issue.”

Case Study 2: Managing Corrosive Waste for Eco-Clean Services Ltd.

The Challenge: Eco-Clean Services Limited is a company that provides the different needs of the power industry in the Asia-Pacific region. The place they have in mind is a remote mining site close to Perth, Australia, where they require safe, long-term storage for Class 8 corrosive waste. Furthermore, they desired the result to be priced reasonably. One of their inquiries was whether they could buy a used Dangerous Goods Container.

The Solution: I helped them understand the benefits and drawbacks of a new versus a used Dangerous Goods Container for sale. In the end, they decided on new, custom 10-foot containers from ZN MEOX. The reason for these units was that they had special acid-resistant linings. With that, they could guarantee complete containment and a long service life, even under the tough Australian climate. Additionally, I was there to support them in the process of compiling the necessary documents to comply with Hazmat container leasing requirements for the short-term units.

Testimonial: Dr. Amina Rahman, the Lab Safety Officer at Eco-Clean, reported: “We deal with different dangerous goods classes. These ZN MEOX containers provide safe segregation and are airtight and leak-proof. The extra reassurance has been priceless during our safety audits.”

For comprehensive details regarding compliance issues, integrated safety systems, technical specifications, and the full range of Dangerous Goods container types offered by ZN MEOX, please refer to our product description page here.

Conclusion: Safety is the Final Destination

It’s a big call when you transport hazardous materials. During that time, one thing is very crucial: strict adherence to the rules without any compromise.

Throughout this discussion, I have repeatedly mentioned that it takes a lot of different experts to understand the UN classifications and the IMO tank container specifications. Also, through my actual work, I have proved that choosing the right Dangerous Goods Container is the best way to both prevent the situation from going out of control and evade heavy regulatory fines. Only the specially designed Dangerous Goods Container can ensure the fulfillment of such tough international standards.

It is far from just a buy; it is a significant step towards being reliable and the continued operation of your business. By buying the right container, you are keeping your money, your people, and the earth safe.

Don’t risk fines or environmental disaster by guessing your compliance needs. Contact the ZN MEOX expert team today to ensure your cargo meets every international and domestic standard, safeguarding your investment and your reputation.

FAQs

What is the lifespan of a Dangerous Goods Container?

A Dangerous Goods Container that is kept in good condition can still be functional for 20 to 30 years. It is absolutely necessary to carry out maintenance regularly. Maintenance should also include repainting and making sure the structure of the floor and walls is sound. The life span is extended to a great extent by the mentioned C3 to C5 paint coating

Who is responsible for classifying the goods?

The shipper or consignor is always responsible. They must accurately classify the goods. They must ensure the container is suitable for that class.

Can I convert a Hazmat container into a storage unit?

Yes, a Dangerous Goods Container is an excellent unit for on-site storage. Since its strong construction is already in accordance with the safety requirements for the storage of hazardous materials, a laboratory or a manufacturing plant becomes the perfect place for it.

This article was last reviewed for compliance on December, 2025 and is based on the updated IMDG/49 CFR standards

Disclaimer: This article provides general information. It is not legal advice. Regulations may change frequently, so shippers should consult current local and international laws for the latest compliance requirements.