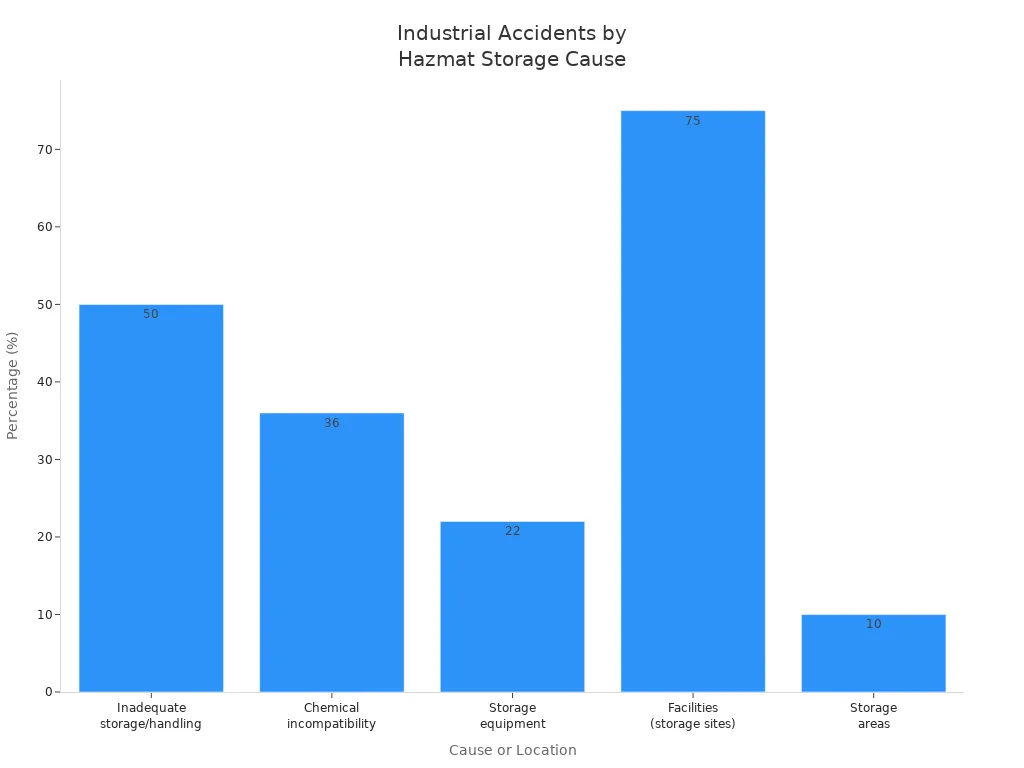

Hazmat storage containers help keep people safe with hazardous materials. Storing hazardous materials the right way stops fires, spills, and exposure. Many accidents happen because hazmat storage is not done well. See the table below:

Cause/Location of Accident | Percentage |

|---|---|

Incidents related to inadequate storage/handling | ~50% |

Accidents caused by chemical incompatibility | 36% |

Accidents occurring in storage equipment | 22% |

Hazmat emergencies at facilities (storage sites) | 75% |

Hazmat emergencies in storage areas | 10% |

You need certified hazmat storage containers for safety and rules. MEOX gives special solutions for storing hazardous materials.

Key Takeaways

Hazmat storage containers help keep people safe. They also protect the environment from harm. These containers stop fires, spills, and contact with dangerous chemicals. Using the correct container for each hazardous material is important. Following safety rules helps stop accidents, fines, and health problems. Check and take care of containers often. Make sure chemicals have clear labels. Train workers so hazmat storage stays safe and works well.

Hazmat Storage Containers Overview

What Are Hazmat Storage Containers

Hazmat storage containers are made to keep hazardous materials safe. People use them to store, move, and handle dangerous chemicals and gases. These containers have thick walls and strong locks. They also have vents to let air flow. These features help stop leaks, spills, and fires. Hazmat containers are not like regular storage containers. They use fire-retardant materials and have extra layers to catch spills. Each container has clear labels and markings. The labels tell you what kind of hazard is inside.

There are many types of hazmat storage containers in the United States. Some common ones are:

Drums: These can be steel, plastic, or fiber. They hold liquids, powders, or solids. Drums come in sizes like 30 or 55 gallons.

Intermediate Bulk Containers (IBCs): These are made from plastic or metal. They hold large amounts of liquids or granules. Most IBCs hold between 275 and 330 gallons.

Cylinders: These are made from strong steel or aluminum. They carry gases like propane or chlorine.

Tanks and Tankers: These are big containers for moving dangerous liquids and gases. They include portable tanks, cargo tanks, and rail tank cars.

Overpacks: These cover damaged or leaking packages to stop spills.

Lab Packs: These are small bottles or vials packed in drums. Labs use them for chemical waste.

Specialty Containers: These include cryogenic containers for very cold gases. Some are for radioactive materials or medical waste.

Hazmat containers must follow strict rules from groups like OSHA, DOT, and the UN. You need to check them often for damage, leaks, or missing labels. MEOX has many hazardous material containers that meet these rules. Some have double doors, side openings, or special racks to help you organize better.

Why Hazardous Materials Storage Matters

Storing hazardous materials the right way keeps people and the environment safe. If you store chemicals wrong, accidents can happen. For example, in 2013, a fertilizer plant in Texas exploded. Workers kept ammonium nitrate in open bins near things that could catch fire. This killed 15 people and hurt 160 more. In 2015, a warehouse in China exploded because chemicals were stored wrong. This caused 173 deaths and hurt the environment for a long time.

If you do not use the right hazmat storage container, you face many dangers:

Health hazards: Toxic fumes or spills can hurt your lungs or skin. They can even kill you.

Fire and explosion: Some chemicals can catch fire if stored together or near heat.

Environmental contamination: Leaks and spills can pollute the ground, water, and air.

Regulatory violations: Not following OSHA or EPA rules can mean fines or legal trouble.

Emergency response problems: Bad storage makes it hard for firefighters to help fast.

Most accidents in storage places happen because of chemical mixing, wrong equipment, or spills. You can stop these problems by using the right hazmat containers. Label chemicals clearly and keep dangerous substances apart. MEOX has solutions to help you do these things. Their containers have bunded floors, vents, and strong locks to keep hazardous materials safe.

Tip: Always look at the Material Safety Data Sheet (MSDS) for each chemical. The MSDS tells you how to store, handle, and get rid of hazardous materials safely.

Types of Hazardous Materials

Hazardous materials come in many forms. Each type needs special storage to keep everyone safe. The table below shows the main types and what they need:

Hazardous Material Category | Description | Key Characteristics | Specialized Storage Requirements |

|---|---|---|---|

Flammable Liquids (Class IA, IB, IC) | Liquids that catch fire below 100°F | Low flashpoints, high fire risk | Store in approved safety cabinets with volume limits |

Combustible Liquids (Class II, IIIA, IIIB) | Liquids that catch fire at higher temperatures | Higher flashpoints | Store in safety cabinets with class-specific limits |

Flammable Solids | Solids that burn easily | Risk of ignition from friction or heat | Store in cabinets away from ignition sources |

Oxidizers | Substances that release oxygen | Support combustion, react with organics | Store in cabinets that limit air exposure |

Corrosives | Liquids that corrode metals | Cause burns, damage containers | Store in corrosion-resistant cabinets |

Poisons | Toxic substances | Harmful to health, need secure containment | Store in labeled, locked cabinets |

Compressed Gases | Gases under pressure | Risk of leaks or explosions | Store in secured cylinders or cabinets |

You must use the right hazmat storage container for each hazardous material. Flammable liquids need steel cabinets that resist fire. Corrosive chemicals need containers made from special plastic or lined steel. Toxic materials need extra layers to stop leaks. MEOX has containers with spill sumps, racks you can move, and strong vents. These help you follow OSHA and NFPA rules for safe storage.

When you move hazardous materials, you need containers that can handle bumps, pressure, and heat changes. MEOX containers use strong steel, coatings that stop rust, and secure locks. You can pick the size and layout that fits your needs.

Note: Always keep acids away from bases, and flammables away from oxidizers. Use clear labels and keep a list of what you have to lower risk.

Hazmat storage containers are important for moving chemicals, keeping workplaces safe, and protecting the environment. By picking the right container and following good rules, you keep people, property, and the planet safe.

Key Features and Compliance

Hazmat Containers vs Standard Containers

You may wonder how hazmat containers are different from regular ones. Hazmat containers use special materials and designs for safety. They follow strict rules to keep people safe. Here are some main differences:

Hazmat containers can stay safe in a fire for two or four hours. They protect what is inside if there is a fire.

These containers have sumps that catch leaks and spills. This stops hazardous materials from getting into the environment.

They have explosion-proof lights and vents. These lower the chance of fire or explosion.

Regular containers do not have these safety features. They cannot meet the rules for storing hazardous materials.

Feature | Hazmat Containers | Standard Containers |

|---|---|---|

Fire Resistance | 2-4 hour fire rating | No fire rating |

Spill Containment | Built-in sumps | None |

Explosion-Proof Systems | Yes | No |

Regulatory Compliance | Meets OSHA, NFPA, ISO | Not compliant |

Cost (20ft, purchase) | ~$15,000 | Lower |

Hazmat containers cost more money. But they give better protection for people and the environment.

Essential Safety Features

Hazmat containers need strong safety features to store hazardous materials safely. Look for these things:

Double walls help stop leaks.

Fire-retardant coatings slow down fire damage.

Secondary containment holds more than the biggest container inside.

Materials that resist corrosion are good for acids and bases.

Secure locks and doors that close by themselves.

Vents take out dangerous fumes.

Labels and warning signs show hazards clearly.

You should check and fix containers often.

MEOX Dangerous Goods Containers have all these features. They also have sensors to watch for problems and racks you can move to organize better.

Tip: Always look for cracks, rust, or leaks when you check your containers. This helps keep your hazmat storage safe and following the rules.

Regulatory Standards for Hazmat Storage Container

You must follow strict rules for storing hazardous materials. OSHA, NFPA, and ISO make the main rules:

OSHA says you need fire-rated walls, spill sumps, and clear signs.

NFPA has rules for storing flammable liquids, fire safety, and vents.

ISO rules make sure containers are strong and safe for shipping.

If you do not follow these rules, you can get big fines every day. You might also get sued or lose your business license. Always train your workers and keep up with new safety rules.

MEOX Dangerous Goods Container Solutions

MEOX makes hazmat containers that meet all the big safety rules. Their containers have certifications like CSC, IMDG, ADR, and UN. You get double-walled steel, fire coatings, and strong spill systems. MEOX uses materials that do not rust and sensors that check safety all the time. These features help you store hazardous materials safely and protect people, your site, and the environment.

Benefits and Best Practices of Hazmat Storage Containers

Safety and Efficiency Benefits

Using hazmat containers gives you many good things. These containers help stop accidents and keep your workplace safe. Good air flow and the right temperature stop bad fumes and keep chemicals stable. Clear labels help you find hazards fast. Training workers and having emergency plans help you act quickly if there is a spill or fire. Checking containers often helps you find leaks or damage early.

Here is how good hazmat containers help your work:

Benefit | Description |

|---|---|

Accident Prevention | Stops leaks, spills, and fires before they start |

Cost Savings | Reduces insurance costs and avoids fines |

Product Protection | Keeps hazardous materials secure and undamaged |

Operational Efficiency | Makes loading, unloading, and inventory easier |

Long-Term Savings | Durable containers last longer and need fewer replacements |

You also show customers and partners that you care about safety and protection.

Choosing the Right Hazmat Storage Container

Picking the right hazmat container is important for safety. You must match the container to the hazardous material. Check if the container is the right size and has good air flow. Make sure it meets OSHA and EPA rules. Use containers with spill catchers, fire protection, and strong locks.

Some people make mistakes like using bad labels, not checking for leaks, or mixing chemicals that should not go together. Always keep acids away from bases and flammables away from oxidizers. Use clear labels and keep a list of what you store. MEOX has containers with racks you can move, strong locks, and good air flow to fit your needs.

Tip: Use Safety Data Sheets to check if a container is right for each hazardous material.

Maintenance and Safe Use

You need to check hazmat containers often. Look for rust, cracks, or leaks. Clean sumps and grates so nothing blocks them. Test alarms and fire systems to make sure they work. Write down every check and repair. Teach your team how to handle containers safely and what to do in an emergency.

Experts say you should check containers at least once a year. Some containers may need more checks if you use them a lot or if they hold risky materials. Taking care of containers helps them last longer and keeps hazardous materials safe.

Note: If you do not take care of containers, you could have spills, hurt the environment, or get big fines. Always follow the maker’s instructions for care and replacement.

When you use certified storage, you keep people safe. You also protect property and the environment.

Real events show that bad storage and slow action cause fires and leaks. These problems can make people leave the area.

Always follow safety rules. Train your team well. Have emergency plans ready at all times.

Pick strong containers like MEOX to help keep things safe.

FAQ

What should you do if your hazmat container leaks?

Stop using the container right away. Move the hazardous materials to a safe spot. Ask MEOX support for help with fixing or replacing it.

How often should you inspect your hazardous material container?

Check your container at least once every year. If you use it a lot or store dangerous chemicals, check it more often.

Can you store different hazardous materials together in one container?

Only put different materials together if the container keeps them apart. Always read the safety data sheets and ask MEOX if you are not sure.