Side-opening shipping containers are becoming popular day by day for their unique designs, rapid deployment, and sustainability features. Next-generation portable commercial spaces require buildings that are free from conventional constraints; in fact, they should be capable of being opened entirely to the customer. The requirement for absolutely free sightlines and access is fulfilled in an ideal manner by the ‘Side-opening Shipping Container’.

Side-opening shipping containers are constructed from heavy-duty, climate-resistant steel. The entire long side of the container can be opened with the help of hinged or bi-fold doors, thus allowing personnel and equipment seamless internal access. With such a design, the handling of large or bulky items, be it loading or unloading, becomes extremely comfortable, a significant advantage over conventional end-door models. Such a design turns the container into a much more comfortable unit compared to a common end-door container. It shortens the time the goods are handled and eases access to the cargo. Side-opening shipping containers are nowadays reconditioned by a great number of users into storage, workshops, or makeshift offices. Their versatility is in accordance with the increasing need for mobile, easily changeable spaces in logistics, construction, events, and the work of remote sites.

Fig. 1: A side-opening shipping container

As the Manager-Modular Solutions at MEOX, I have been instrumental in managing and executing various complex projects in the challenging markets of South Asia and Europe for six years. I specialize in container conversions, structural compliance, and modular office and workshop solutions for extreme weather environments. Based on this specialized experience, I am writing this article to elaborate on the exact manner in which the planned use of side-opening shipping containers is reshaping the operational flexibility of different sectors like modern workshops, offices, and storage facilities worldwide.

What Is a Side-opening Shipping Container?

A side-opening shipping container is a metal freight container that has been designed in a way that the long side can be opened fully, as opposed to the usual containers, which have only end doors. MEOX side-opening shipping containers are constructed of 4 mm-thick, high-strength steel; thus, they are durable and resistant to weather.

Multi-leaf hinged doors are used to open the side wall, thus forklifts, pallet trucks, or personnel can easily access the interior. Loading and unloading of bulky or irregularly shaped items is by far much more comfortable when you use a large side-opening shipping container than a standard end-door container. Besides, a big side-opening container is an excellent way to have a flexible interior that can be easily converted into storage, a workshop, or a temporary office.

As these containers contain corner reinforcements and strong steel frames, they are capable of holding on to their structural strength even after they have been modified. Their layout is a combination of portability, robustness, and versatility, which makes them perfect for use in modern modular and industrial sectors.

Top Uses and Applications of Side-Opening Shipping Containers

Open-sided or side-opening shipping containers are flexible units that are commonly used in various industries. Because of their fully accessible side, they are perfect for any application in which large items, equipment, or frequent access are needed.

Side-opening shipping containers are great, specifically for holding voluminous or palletized materials. With the entire side of the container available, vehicles like forklifts and pallet trucks can easily and quickly load and unload the products. These types of containers, as a rule, can be found in storerooms, at building sites, and in the various stages of transport and distribution, where the facilitation of the work is of great importance and is time-saving.

Such containers may be transformed into workspaces for the repair of machines, fabrication, or the implementation of creative projects. The door that opens on the side makes it possible to bring in heavy equipment and tools with ease and also offers different possibilities of arranging workbenches, racks, and air-conditioning units.

Side-opening shipping containers are outstanding options too, for a mobile or isolated temporary office. By simply adding insulation, windows, HVAC, and electrical systems, they can be transformed into comfortable work environments. The large side opening facilitates the alteration of the interior layout, so they are the best places to be at a construction site, an event, or a remote project office.

Fig. 2: Inside view of a side-opening shipping container

Different Types of Side-Opening Shipping Containers and Their Storage Options

Most of the time, you can find open-sided shipping containers in 20-foot and 40-foot sizes. Here are the measurements of standard containers with open-sided cargo doors:

20ft Side Opening Shipping Container

The 20-foot side-opening shipping container is single-handedly a very flexible choice to be used for freight and kept in a limited space type of storage, especially where space is a constraint for end-door access.

| Dimensions | Imperial | Metric |

| External Length | 20′ 0″ | 6.058 m |

| External Width | 8′ 0″ | 2.438 m |

| External Height | 8′ 6″ | 2.591 m |

| Interior Length | 19′ 4″ (approx. 5.898m) | 5.898 m |

| Interior Width | 7′ 6″ (approx. 2.288m) | 2.288 m |

| Interior Height | 7′ 6″ (approx. 2.299m) | 2.299 m |

| End Door Dimensions | 7′ 8″ W x 7′ 5″ H | N/A |

| Weight (Tare) | 5,072 lbs. | 2,300 kg |

| Capacity | 1,095 cu. ft. (approx. 31 m³) | 31 m³ |

Table 1: Dimensions of a 20ft Side-opening Storage Container

40ft Side-opening Shipping Container

| Specification | Imperial | Metric |

| External Length | 40′ 0″ | 12.192 m |

| External Width | 8′ 0″ | 2.438 m |

| External Height | 9′ 6″ | 2.896 m |

| Interior Length | 39′ 5″ | 12.032 m |

| Interior Width | 7′ 8″ | 2.348 m |

| Interior Height | 8′ 9″ | 2.699 m |

| End Door Dimensions | 7′ 8″ W x 8′ 5″ H | N/A |

| Weight (Tare) | Approx. 8,500 lbs. | Approx. 3,860 kg |

| Capacity (Volume) | Approx. 2,698 cu. ft. | Approx. 76.4 m³ |

Table 2: Dimensions of a 40ft Side-opening Storage Container

Unlocking Efficiency: Key Features and Advantages for Workshops & Mobile Sites

The global demand for shipping containers is on the rise. People are increasingly opting to buy shipping containers instead of conventional storage systems for their workshops and mobile sites. A report published by Market.us states that the global shipping container market size is projected to be reached about 15.7 billion USD by the year 2034, up from 10.7 billion USD in 2024, with a CAGR of 3.9% over the forecast period of 2025 to 2034.

Again, according to Grand View Research, the worldwide modular construction industry was valued at around 103.55 billion USD in 2024 and is anticipated to grow up to 162.42 billion USD by 2030, with a CAGR of 7.9% during the period 2025-2030

Side-opening shipping containers are the most convenient and practical storage units, perfect for mobile offices and workshops. Their appealing structure makes them a safe and efficient way to flexibly convert your workspace. The main features are:

- Easy Side Access for Bulky or Palletized Items

- Greater Flexibility for Conversions

- Ground-Level and Heavy Equipment Accessibility

- Strong Structural Integrity

| Feature | Practical Benefit | Best Use Case |

| Full-length side access | Faster loading and unloading of large or palletized items | Warehouses, logistics hubs, bulk storage |

| Wide opening for interior layout | Easy installation of benches, racks, or office partitions | Workshops, modular offices, creative studios |

| Ground-level access | Safe and simple forklift or equipment entry | Construction sites, heavy-equipment storage |

| *Reinforced steel structure | Strong durability and weather resistance | Long-term outdoor storage, industrial sites |

| Flexible modification potential | Smooth customization for utilities or insulation | Remote offices, mobile work units, field operations |

Table 3: Key Features, Benefits, and Best Use Cases of Side-opening Shipping Containers

*Side-opening containers are made of reinforced steel and have multi-leaf hinged doors that provide not only strength but also flexibility. The strength of the body corresponds to the standards of ISO 6346 that regulate the safe and long-lasting design of containers.

Alternatives to Side-opening Shipping Containers

Side-opening shipping containers ensure wide access and are highly flexible, but there are users who might have to get different types of containers for tailored applications. There are a lot of options available that can cater to your loading, security, or interior layout requirements.

Standard ISO Shipping Containers: A typical container is equipped with two doors at one end. This type suits general cargo, secure storage, and long-distance shipping. When there is no full need for side access, it becomes a cost-effective solution.

Double-Door Containers: A double-door container is one that has doors located at both ends. This characteristic basically raises the work process level as users can load things from the side that they prefer. In fact, it is extremely efficient for such materials that require being sorted or accessed frequently.

Open-Top Containers: The open-top container comes with either a removable roof or a tarp. The container is perfect for tall machinery, oversized equipment, or irregular items that require vertical loading with a crane. Besides that, it can be helpful when the goods are too big to be taken through a standard front door.

Fig. 3: A 40 ft side opening shipping container

Flat-Rack Containers: The flat-rack container is one with folding or fixed end walls. It is most appropriate for heavy machinery, vehicles, or industrial elements, the side-lifting method to be used. Besides that, it is suitable for non-standard-sized freight that cannot be packed inside a regular container.

Tunnel Containers: A tunnel container is one that has doors on both ends, just like a double-door model. However, it often comes with security hardware that is significantly more robust. The main purpose of the container is to be used in logistics operations needing through-loading or inventory rotation as fast as possible.

Refrigerated (Reefer) Containers: Reefer containers are those that can maintain the temperature of the items kept inside them. The container is perfect for foodstuffs, pharmaceuticals, and other temperature-sensitive materials. Side access was never an intention, but the container offers the much-needed climate control that a side-opening shipping container can never provide.

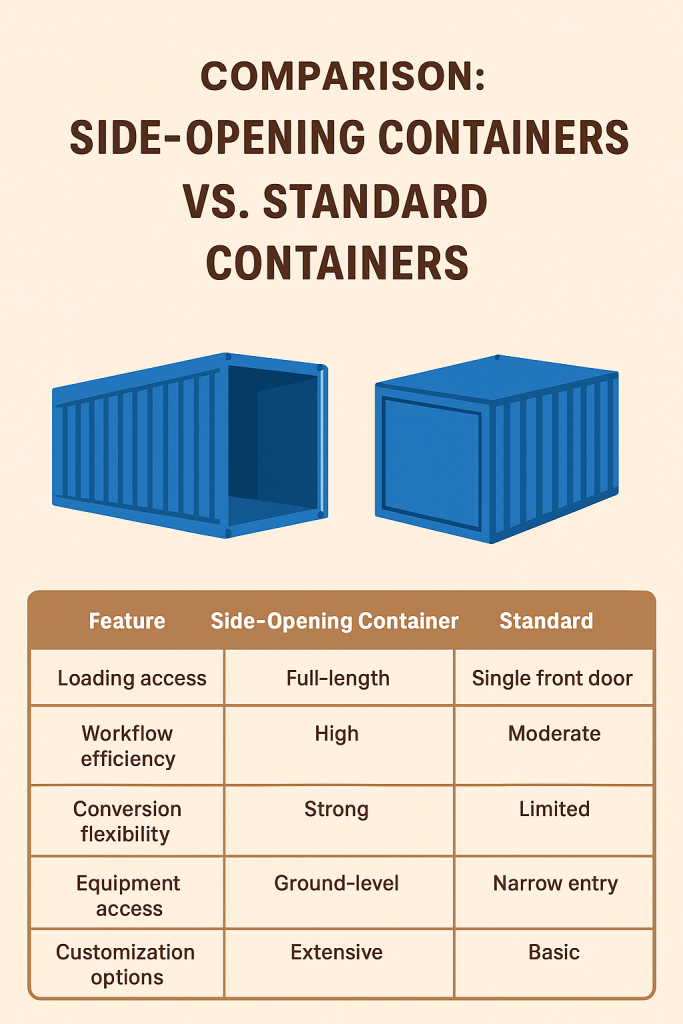

Comparison: Side-opening Shipping Containers vs. Standard Containers

If we compare a side-opening shipping container with a regular one-door container, the first one is more advantageous in a number of ways. With the full-length side access, the container becomes more user-friendly, its storage capacity increases, and it also becomes convertible to other uses more easily. Regular containers are still a good solution for the transport of general cargo, but they are not as accessible and flexible as a side-opening unit. People who have a necessity for frequent loading, workshop layouts, or modular office spaces are the ones who will most probably decide to go for a side-opening shipping container, as the design is more flow-efficient. On the other hand, standard containers can still be considered as a cheap enough option when there is no need for wide access.

Fig. 4: Side Opening vs. Standard Containers

Real-World Case Studies: How Side-Opening Shipping Containers Improve Operations

Case Study -1: Logistics & Operational Efficiency in Germany

Project: Rapid-Deployment Parts Depot (Germany, 2024)

Challenge: A third-party logistics (3PL) provider, a major European logistics firm, was in dire need of high-access storage for palletized vehicle parts. They were facing bottlenecks from regular end-door containers.

Solution: We deployed 40ft Side Opening Containers, allowing forklifts to access the entire side, eliminating double-handling of pallets.

Result: The company achieved a 40% reduction in average pallet retrieval time and streamlined inventory flow.

Testimonial:

“The working difference is as different as night and day. We have significantly reduced our labor hours for inventory checks. With the full-side access, what was once a storage problem has now been turned into a streamlined, fast-moving parts depot. We really appreciate ZN House for their great side-opening shipping container.”

— Martin Krenz, Warehouse Operations Director, EuroLogistics Inc., Germany

Case Study -2: Remote Site Operations & Extreme Weather in India

Project: Mobile Workshop for Himalayan Infrastructure Project (India, 2023)

Challenge: A construction consortium needed a safe, weather-resistant, and easily reachable mobile workshop for large fabrication machinery at a high-altitude, remote location.

Solution: We supplied a 20ft modified side-opening high cube container, which was highly insulated and had side access that enabled a gantry crane system and materials to be moved straight in and out over rough terrain.

Result: The full-side access was the main reason for almost doubling the speed with which the equipment was deployed (45%), and it also remained very reliable during bad weather.

Testimonial:

“The side-opening unit from ZN House was a game-changer for our schedule. With it, we were able to safely carry out our workshop directly on the challenging ground, and it stood up to the bad weather without any problems.”

— Rajesh Sharma, Lead Project Manager, HP Infrastructure Solutions, Himachal Pradesh, India

Conclusion

A side-opening shipping container provides a business with a flexible, accessible, and long-lasting space solution that is in line with the needs of modern companies. The container with its full-length access, efficient loading workflow, and strong adaptability is basically the first choice of those industries that require rapid operations, wide movement of the equipment, or fully customized container conversions. The side-opening shipping containers design is there to help you through a vast spectrum of specialized project needs, from building and pop-up retail shows to workshop units and mobile storage. The price might indeed be a bit higher as compared to the standard models, but the operational advantages that you gain from it are often of great value and efficiency in the long run.

If you’re looking for a versatile container that enhances productivity and expands functional possibilities, contact MEOX today for tailored side-opening shipping container solutions.

FAQS

Question: What are Open-Side Containers Used For?

Answer: Open side containers serve versatile storage needs, facilitate the simple loading and unloading of bulk or palletized goods, and may be transformed into workshops, offices, or artistic areas.

Question: Do shipping containers have openings at both ends?

Answer: Yes, certain shipping containers feature openings at both ends, which are called double-door containers, and hence facilitate loading and unloading operations from either side more efficiently.

Question: What are the available sizes for side-opening containers?

Answer: Generally, side-opening containers come in sizes of 20 feet and 40 feet, both of which provide versatile storage and simple access for the loading and unloading of large pieces of freight.

Question: What is the cost associated with buying a 20 ft. open-sided container?

Answer: The price for a 20 ft. open-sided container is determined by various factors such as the container’s condition (new or used), customization, location, and the supplier. For a quote that is tailored to your needs and requirements, it is most advisable to get in touch with ZN House.

Question: Are side-opening containers weather-resistant?

Answer: Yes, they are made from durable, weather-resistant steel, ensuring they can withstand harsh conditions and provide reliable protection for goods and equipment.

Disclaimer

The information provided in this article is for general guidance only and may vary depending on regional regulations, project requirements, and manufacturer specifications. ZN MEOX recommends verifying all technical details and compliance needs with qualified professionals before making any purchasing or construction decisions.