You use a dangerous goods container to safely store and transport hazardous materials. These containers protect you, your property, and the environment from leaks, spills, or other risks. Each container features special designs that handle specific dangers. Just as an arabic men head scarf offers both tradition and practical protection, these containers combine safety with thoughtful engineering.

Key Takeaways

- Dangerous goods containers keep hazardous materials safe by using strong materials, leak-proof seals, and clear labels to prevent accidents and spills.

- Choosing the right container means matching it to the chemical inside and following safety tests and compatibility charts to avoid dangerous reactions.

- Following strict regulations and using certified containers helps you stay legal, avoid fines, and protect people and the environment.

- Regular inspections, proper labeling, and staff training are key to the safe handling, transport, and storage of dangerous goods.

- Using the correct container reduces risks, protects communities, and ensures your shipments arrive safely and on time.

Key Features of Dangerous Goods Containers

Reinforced Construction

You need a container that stands up to tough conditions. Dangerous goods containers use reinforced construction to protect against impacts, pressure, and harsh environments. Manufacturers select strong materials like steel or high-grade plastics. These materials resist corrosion and damage from chemicals. You can trust these containers to keep hazardous materials secure, even during rough handling or long journeys.

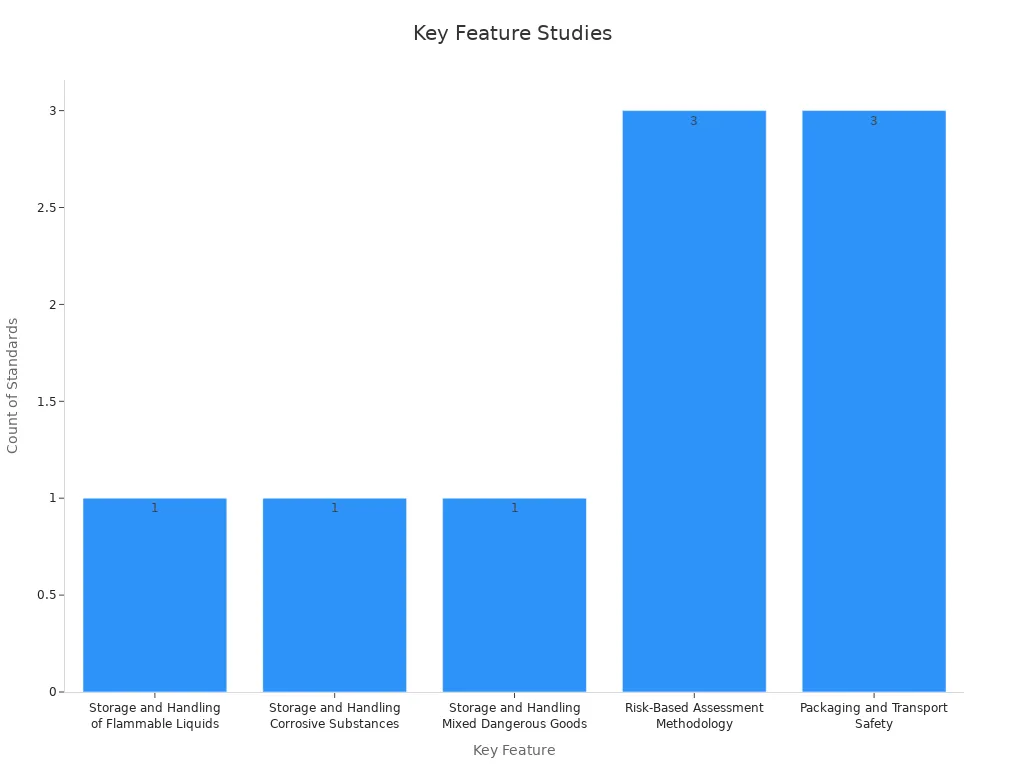

A variety of safety standards guide the construction of these containers. For example, AS 1940:2017 and AS 3780:2023 set requirements for storing flammable and corrosive substances. These standards focus on fire protection, spill containment, and separation distances. The table below shows how different standards support the safe design and use of dangerous goods containers:

| Key Feature | Supporting Standard(s) | Description and Safety Measures |

|---|---|---|

| Storage and Handling of Flammable and Combustible Liquids | AS 1940:2017 | Guidelines on storage tanks, piping, separation distances, ventilation, fire protection to minimize fire/explosion risks. |

| Storage and Handling of Corrosive Substances | AS 3780:2023 | Requirements for container materials, spill containment, PPE, labeling, and safe handling to prevent chemical burns and environmental harm. |

| Storage and Handling of Mixed Classes of Dangerous Goods | AS/NZS 3833:2007 | Segregation of incompatible materials, emergency response procedures, labeling, and safe transport of mixed DG classes. |

| Risk-Based Assessment Methodology | AS 1940, AS 3780, AS/NZS 3833 | Systematic hazard identification, risk evaluation, ALARP principle application, and control maintenance to ensure ongoing safety. |

| Packaging and Transport Safety | He et al. (2017), Flodén & Woxenius (2021), Schlick-Hasper et al. (2018, 2020) | Computational models for transport optimization, stakeholder frameworks, and industrial packaging testing to enhance safe handling and transport. |

You can see how many standards support each safety feature in the chart below:

Leak-Proof Seals

You want to prevent leaks and spills at all times. Dangerous goods containers use leak-proof seals to keep hazardous materials inside. These seals use advanced materials and designs. Rubber gaskets, welded seams, and locking mechanisms all help stop liquids or gases from escaping. You reduce the risk of accidents and environmental harm by using containers with reliable seals.

Tip: Always check the condition of seals before using a container. Even a small crack or gap can lead to dangerous leaks.

Clear Labeling and Markings

You must identify the contents of a dangerous goods container quickly and accurately. Clear labeling and markings help you do this. Labels show hazard symbols, UN numbers, and hazard class indicators. Markings include the product name, manufacturer, and emergency instructions. These details help you and emergency responders know what is inside and how to handle it safely.

International regulations such as ADR, IMDG, and IATA require strict labeling and documentation. Here are some important labeling requirements:

- Labels must include hazard symbols, UN numbers, and hazard class indicators.

- Containers require clear markings including product name, hazard class, UN number, and manufacturer information.

- Documentation must detail hazards, safety precautions, and emergency instructions.

- Compliance with international regulations such as ADR, IMDG, and IATA is mandatory.

- Label and documentation language must be appropriate for the destination or internationally recognized.

- Labels must remain visible and legible throughout transportation and handling.

- Personnel handling dangerous goods must be trained on marking and labeling requirements.

You help ensure safety and legal compliance by following these rules. Clear labeling also speeds up emergency response and reduces the chance of mistakes during transport or storage.

Compatibility with Hazardous Materials

When you choose a dangerous goods container, you must make sure it matches the chemical properties of the materials you want to store or transport. Not every container works for every chemical. Some materials can react with the container itself, causing leaks, spills, or even dangerous reactions.

You can rely on several methods to check if a container is compatible with hazardous materials:

- Compatibility testing happens at different time frames: short-term (up to 30 days), intermediate (up to 4 months), and long-term (over 4 months). These tests help you see how the container holds up over time.

- Standard test methods include EPA 9090, NSF 54, ASTM D543, ASTM D471, ISO 175, DIN 53-521, and BS 4618. These tests often involve soaking the container material in chemicals and checking for changes.

- The type of polymer used in the container matters. Common choices include PVC, LDPE, HDPE, EPDM, and neoprene. Each has its own strengths and weaknesses against different chemicals.

- Chemical resistance depends on factors like thickness, color, and reinforcement of the material.

- No single test tells you everything. You should also look at real-world experience and consult compatibility charts.

- Some chemicals, especially mixtures, can behave in unpredictable ways. Always check the Safety Data Sheet (SDS) and use chemical compatibility charts before making your choice.

- Segregate incompatible chemicals to prevent dangerous reactions during storage or transport.

Tip: Always inspect containers for signs of softening, swelling, or cracking. These changes can mean the container is not compatible with the chemical inside.

You should also follow these steps to ensure safety:

- Make sure the hazardous material does not react with the container or its parts.

- Use only containers that resist corrosion, softening, and aging.

- Separate incompatible chemicals to avoid dangerous reactions.

- Check regulatory guidelines like 49 CFR, IATA, and IMDG for compatibility requirements.

- Use glass containers only for chemicals that do not attack glass, such as avoiding fluorine or hydrofluoric acid.

- Consult technical teams and conduct laboratory tests when in doubt.

By following these guidelines, you help prevent leaks, spills, and accidents. You also protect yourself, others, and the environment from harm.

Compliance with Regulations

You must follow strict regulations when you store or transport dangerous goods. These rules help keep everyone safe and protect the environment. Many organizations and government agencies set these standards.

Some of the main groups and regulations you should know include:

- The U.S. Coast Guard’s Office of Port & Facility Compliance oversees dangerous goods containers in the United States. Key divisions like Hazardous Materials Division, Inspections & Compliance, and the Marine Safety Center manage inspections and equipment approvals.

- International rules such as the IATA Dangerous Goods Regulations (DGR) provide detailed instructions for classifying, packing, documenting, and handling dangerous goods. These rules update every year to stay current.

- The DGR covers what you can ship, how to pack it, what paperwork you need, and how to report incidents.

- Using the latest DGR helps you avoid delays, fines, and lost contracts. It also ensures you meet international safety standards.

- Other important regulations include 49 CFR in the United States and the IMDG Code for sea transport.

Note: Regulatory agencies may inspect your containers and shipping records at any time. Keeping up with the latest rules helps you pass inspections and avoid penalties.

You have a responsibility to:

- Make sure your containers meet all legal requirements.

- Train your staff on proper handling and documentation.

- Keep records of inspections and compliance checks.

- Stay updated on changes to regulations.

By following these regulations, you show that you care about safety and professionalism. You also help prevent accidents and protect your business from costly mistakes.

Types of Dangerous Goods Containers

When you handle hazardous materials, you need the right container for the job. Different types of dangerous goods containers serve specific purposes and industries. The global market for these containers reached $12.5 billion in 2023 and is projected to grow to $18.8 billion by 2032, driven by strict regulations and the need for safe transport. Here’s a quick look at the market landscape:

| Aspect | Details & Statistics |

|---|---|

| Market Size (2023) | USD 12.5 billion |

| Projected Market Size (2032) | USD 18.8 billion |

| CAGR | 4.5% |

| Key Container Types | Drums, IBCs, Cylinders, Cans |

| Leading Industries | Chemicals, Pharmaceuticals, Oil & Gas, Agriculture |

| Regional Insights | Asia Pacific fastest-growing; North America and Europe significant shares |

Drum Containers

You often see drum containers in industries like chemicals, oil, and waste management. Drums come in two main types: closed head (for liquids) and open head (for solids). Closed head drums have fixed tops and threaded openings, making them ideal for flammable or reactive liquids. Open head drums feature removable lids, which work well for powders or sludges.

- Drums must pass strict UN performance tests, including drop and stack tests.

- Salvage drums require extra pressure testing and must meet specific volume and weight limits.

- Thicker walls and reinforced seams help drums withstand impacts and leaks.

Always use the correct fittings and closures to maintain certification and safety.

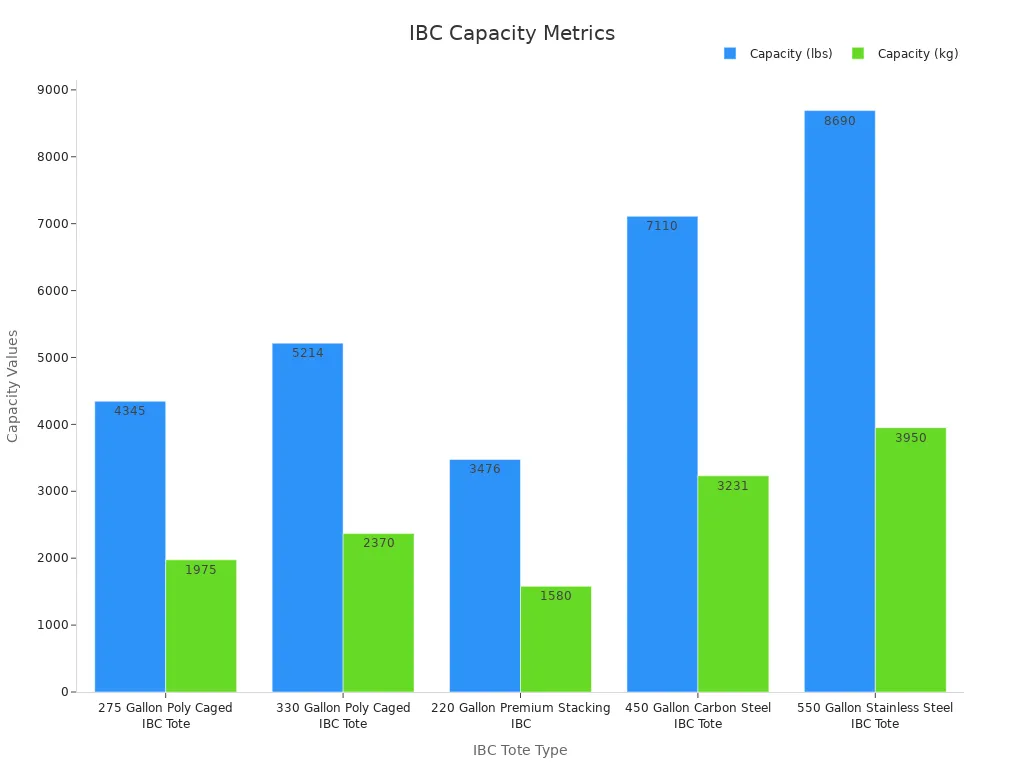

Intermediate Bulk Containers (IBCs)

IBCs give you a flexible solution for transporting large volumes of hazardous materials. These containers range from 220 to 550 gallons and can be made from plastic, steel, or composite materials. You find IBCs in industries that need to move chemicals, pharmaceuticals, or food ingredients.

- Always inspect IBCs for damage or leaks before use.

- Follow maintenance schedules and keep records of inspections.

- Never overload an IBC, as this can cause structural failure and legal issues.

- Label IBCs clearly and use secondary containment when required.

Gas Cylinders

Gas cylinders store and transport compressed gases under high pressure. You use them for medical gases, industrial chemicals, and specialty applications. Regulations like 49 CFR 175.10 set strict limits on the quantity and handling of gas cylinders during transport.

- Only trained personnel should handle gas cylinders.

- FAA and DOT regulations require safety certifications and regular inspections.

- Security restrictions and quantity limits help prevent accidents.

Proper certification and handling keep you and others safe when working with compressed gases.

Tank Containers

You use tank containers to move large volumes of liquid or gas safely. These containers have a strong steel frame and a cylindrical tank inside. You often see them on trains, trucks, or ships. Tank containers handle chemicals, fuels, and even food-grade liquids.

Tank containers stand out for their safety record. Rail transport, which uses many tank containers, is the safest land-based way to move hazardous materials over long distances. You can see this in the table below:

| Evidence Aspect | Description |

|---|---|

| Incident Rate | 99.995% of hazardous materials shipments arrive without incident. |

| Fatality Comparison | Rail releases caused 14 fatalities (1994-2005), while highway releases caused 116 fatalities. |

| Safety Performance | Rail transport has a strong record for safe chemical shipments. |

| Design and Testing | Full-scale tests and research improve tank car designs and safety practices. |

| Industry Cooperation | Groups like the Association of American Railroads set standards and provide training. |

You benefit from strict design standards and ongoing research. Organizations test tank containers for leaks, impacts, and pressure changes. You also rely on proper labeling, packaging, and emergency response plans. These steps help you prevent leaks, spills, and accidents. Continuous improvements in design and operation keep tank containers among the safest options for hazardous material transport.

Tip: Always check that your tank container meets current regulations and has passed recent inspections.

Specialized Freight Containers

You use specialized freight containers when you need to transport dangerous goods that require extra protection. These containers go through tough tests to make sure they can handle shocks, vibrations, and pressure changes during transit. The table below shows some of the main tests and standards:

| Test Type | Purpose/Description | Regulatory Reference |

|---|---|---|

| Shock Resistance | Checks if the container can withstand impacts | UN Model Regulations 6.1 |

| Vibration Tolerance | Tests endurance against transport vibrations | UN Model Regulations 6.1 |

| Differential Pressure | Confirms safety under temperature or altitude changes | UN Model Regulations 6.1 |

| Packing Group Ratings | Matches packaging to the danger level of the contents | US 49 CFR Part 173, TDGRs |

| Performance Ratings | Ensures safe containment of various hazardous substances | US 49 CFR Part 173, TDGRs |

You follow strict rules from the United States, Canada, and international bodies. These rules make sure your containers meet high standards for flammable, corrosive, poisonous, and even radioactive materials. You help protect people and the environment by choosing containers that pass these tests. Always check the container’s certification before use to ensure safe and legal transport.

How Dangerous Goods Containers Work

Preventing Leaks and Spills

You rely on dangerous goods containers to keep hazardous materials secure during storage and transport. These containers use leak-proof seals, reinforced walls, and tight closures to stop liquids or gases from escaping. Regular inspections help you catch any signs of damage, corrosion, or loose lids before a problem occurs. Technical studies show that most dangerous goods releases happen because of mistakes in preparation, packaging, or loading—not from accidents at sea. When you prepare and document your containers correctly, you greatly reduce the risk of leaks and spills. Following packaging standards, such as those set by the Department of Transportation (DOT) and international bodies, ensures that your containers meet strict requirements for impact resistance and leakproof design.

Tip: Always check seals and closures before each use to prevent costly accidents.

Containing Chemical Reactions

Dangerous goods containers do more than just hold chemicals—they help you control and contain chemical reactions. You must use containers made from materials that resist the chemicals you store. For example, high-density polyethylene (HDPE) works well for acids, while stainless steel suits flammable liquids. To keep everyone safe, follow these best practices:

- Inspect containers regularly for leaks, corrosion, or pressure buildup.

- Use secondary containment, like trays or spill pallets, to catch spills if the main container fails.

- Label all containers clearly with chemical names, hazard symbols, and expiration dates.

- Segregate incompatible chemicals to prevent dangerous reactions.

- Dispose of expired or degraded chemicals promptly using proper waste systems.

These steps help you avoid chemical spills, fires, or toxic releases. Laboratory tests and safety standards, such as ANSI Z400.1 and ISO 11014, support these practices by requiring clear labeling and regular inspections.

Ensuring Safe Handling and Transport

You play a key role in safe handling and transport by choosing the right container and following regulations. The Pipeline and Hazardous Materials Safety Administration (PHMSA) reports thousands of hazardous material incidents each year, often linked to improper packaging or handling. By using containers that meet DOT, IATA, and IMDG standards, you help prevent leaks, spills, and accidents. These regulations require containers to be leak-proof, spill-proof, and clearly labeled. When you comply with these rules, you protect yourself, your team, and the environment from harm. Proper training and regular checks make sure your dangerous goods containers work as intended every time.

Meeting Legal and Safety Standards

You must follow strict legal and safety standards when you use dangerous goods containers. These rules protect you, your team, and the environment. Many countries have their own laws, but most follow international guidelines. You need to know the main standards and how to meet them.

Key Standards You Should Know:

- 49 CFR (Code of Federal Regulations): This U.S. law covers the transport of hazardous materials. You must use containers that pass specific tests for strength, leak resistance, and chemical compatibility.

- IMDG Code (International Maritime Dangerous Goods Code): If you ship by sea, you must follow these rules. The IMDG Code sets out how to pack, label, and document dangerous goods.

- IATA DGR (International Air Transport Association Dangerous Goods Regulations): For air transport, you must use containers that meet IATA’s strict requirements. These rules help prevent accidents in the air.

- UN Recommendations: Many countries use the United Nations’ guidelines for classifying, packaging, and labeling dangerous goods.

Note: Always check the latest version of these standards. Rules can change every year.

How You Can Meet These Standards:

- Choose containers that have official certification marks. Look for UN numbers and approval stamps.

- Inspect containers before each use. Check for cracks, dents, or missing labels.

- Train your staff on safe handling and emergency procedures.

- Keep records of inspections, training, and shipments.

- Use clear labels and up-to-date documentation for every shipment.

| Standard | What It Covers | Why It Matters |

|---|---|---|

| 49 CFR | U.S. transport rules | Legal compliance in the U.S. |

| IMDG Code | Sea transport | Global shipping safety |

| IATA DGR | Air transport | Prevents air accidents |

| UN Guidelines | Global recommendations | International consistency |

You show responsibility and professionalism when you follow these standards. You also avoid fines, delays, and accidents. Always stay informed and make safety your top priority.

Importance of Using Dangerous Goods Containers

Reducing the Risk of Accidents

You lower the chance of accidents when you use the right dangerous goods containers. Studies show that many hazardous cargo accidents happen because of poor management, faulty equipment, or human error. For example, the 2015 Tianjin Port explosion and the Beirut port explosion both resulted from the improper handling of dangerous goods. You can see how different factors contribute to these accidents:

- About 20% of accidents are linked to equipment issues.

- Around 41% result from improper or illegal operations.

- Nearly 30% comes from weak safety management.

- Human error accounts for 28% of incidents.

When you choose certified containers and follow safety protocols, you help prevent leaks, fires, and explosions. Regular inspections and proper documentation also play a big role in keeping everyone safe.

Protecting People and the Environment

You protect yourself, your coworkers, and the environment by using dangerous goods containers. These containers stop hazardous materials from leaking into the air, soil, or water. Proper storage and transport keep toxic chemicals away from people and wildlife. Emergency preparedness and well-maintained facilities further reduce risks. When you use the right containers, you help prevent pollution and health hazards. You also support your community by following best practices for hazardous materials.

Remember: Safe handling starts with the right container and careful attention to every step in the process.

Ensuring Legal Compliance

You must meet strict legal requirements when you handle dangerous goods. Regular audits, checklists, and staff training help you stay compliant. If you do not follow the rules, you may face fines or shipment delays. Labels and packaging must meet Department of Transportation (DOT) standards. You also need to complete documents like Dangerous Goods Declarations for every shipment.

| Aspect | Details |

|---|---|

| Key Regulations | U.S. Code of Federal Regulations, Title 49; IMDG Code; IATA Dangerous Goods Regulations |

| IMDG Code Enforcement | Mandatory under SOLAS since 2004 for maritime transport of dangerous goods |

| Penalties for Non-Compliance | Fines up to $77,114 per violation; up to $179,933 if resulting in death, serious injury, or property damage |

| Carrier Compliance Examples | FedEx, UPS, USPS require proper classification, labeling, documentation, and training for HAZMAT shipments |

| Documentation Requirements | Use of UN-approved containers, proper packaging, labeling, and Hazardous Materials Declaration forms |

By following these rules, you avoid costly mistakes and help ensure safe, legal transport of hazardous materials.

Avoiding Costly Fines and Delays

You want your shipments to arrive on time and without extra costs. Using the right dangerous goods containers helps you avoid expensive fines and frustrating delays. Many countries have strict rules for shipping hazardous materials. If you do not follow these rules, you may face penalties or your shipment may get stuck at customs.

Tip: Always check the latest regulations before you ship. Rules can change every year.

Here are some common reasons why companies receive fines or experience delays:

- Incorrect or missing labels on containers

- Using containers that do not meet safety standards

- Incomplete or wrong shipping documents

- Damaged or leaking containers

You can prevent these problems by following a few simple steps:

- Choose containers that have official certification marks.

- Inspect each container for damage before you use it.

- Make sure all labels are clear and easy to read.

- Complete all required paperwork for your shipment.

- Train your team on the latest safety and shipping rules.

The table below shows examples of fines for non-compliance in the United States:

| Violation Type | Possible Fine (USD) |

|---|---|

| Improper packaging | Up to $77,114 per case |

| Missing or incorrect labels | Up to $7,500 per case |

| Incomplete documentation | Up to $1,000 per case |

You save money and time when you follow the rules. Your shipments move smoothly through inspections. Customers trust you more when you deliver on time and without problems. By using certified dangerous goods containers and staying up to date with regulations, you protect your business from costly mistakes.

You play a vital role in safety when you choose the right dangerous goods container. The industry grows each year because strict rules and new technology make containers safer. You see how primary, secondary, and tertiary packaging types help you meet safety and compliance needs. Training and regular checks keep you ready for any risk.

Dangerous Goods Containers FAQ

What makes a container suitable for dangerous goods?

You need a container with strong construction, leak-proof seals, and clear labels. It must match the chemical properties of the material inside. Always check for official certification marks and follow safety standards.

How do you know if a container meets legal requirements?

Look for UN numbers, approval stamps, and clear hazard labels. You should check the latest regulations, such as 49 CFR, IMDG Code, or IATA DGR. Certified containers always display these marks.

Can you reuse dangerous goods containers?

You can reuse some containers if they pass inspection and show no damage. Always clean them properly and check for chemical compatibility. Never reuse a container if it held incompatible or highly reactive substances.

Why is clear labeling important on dangerous goods containers?

Clear labels help you identify hazards quickly. They guide safe handling and emergency response. Labels also ensure you meet legal requirements and avoid costly mistakes.

What should you do if a dangerous goods container gets damaged?

Stop using the container right away. Move it to a safe area. Report the damage to your supervisor. Follow your company’s emergency procedures and use secondary containment if needed.