The versatility of shipping containers has led to groundbreaking applications across multiple industries, with containerized water treatment plant systems revolutionizing access to clean water and shipping container kitchen setups transforming mobile food service. These durable steel structures now support everything from container farm operations to advanced vertical farming shipping containers, demonstrating remarkable adaptability. The emergence of specialized grow room shipping containers further highlights how these modular units can be optimized for controlled environment agriculture, creating sustainable solutions for urban farming and beyond.

The Impact of Containerized Water Treatment Plants

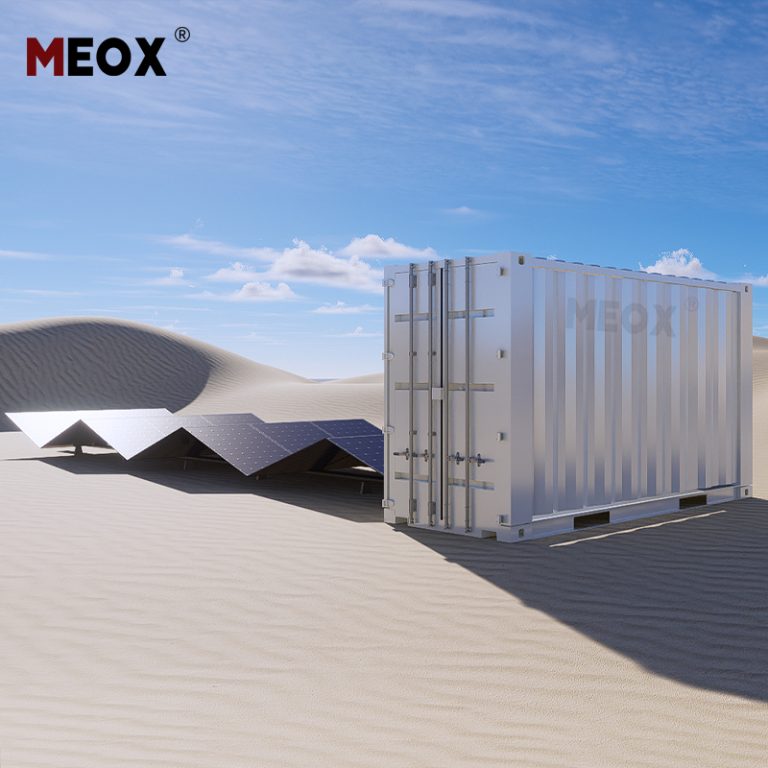

Modern containerized water treatment plant systems provide complete water purification solutions in compact, mobile formats. These self-contained units fit within standard shipping container dimensions while incorporating advanced filtration, chemical treatment, and sometimes desalination technologies. The modular design allows multiple containerized water treatment plant units to be connected for increased capacity, making them ideal for disaster relief, remote communities, and industrial sites. When paired with renewable energy sources, these systems can operate completely off-grid, delivering potable water in challenging environments. The steel construction ensures durability while protecting sensitive membranes and electrical components from harsh conditions, with insulation maintaining optimal operating temperatures in diverse climates.

Shipping Container Kitchens: Mobile Culinary Solutions

The concept of shipping container kitchen installations has gained significant traction across the food service industry and humanitarian sectors. These fully-equipped culinary spaces range from basic food preparation stations to professional-grade commercial kitchens with specialized appliances. The durable steel structure of a shipping container kitchen provides inherent weather resistance while allowing for creative layouts that maximize workspace efficiency. Many designs incorporate stainless steel interiors, commercial ventilation systems, and utility hookups matching conventional kitchen requirements. The mobility factor enables unique applications including pop-up restaurants, disaster response operations, and temporary dining facilities at events. Even permanent installations benefit from faster deployment and lower costs compared to traditional construction, with the added advantage of potential relocation as needs change.

Container Farms: Revolutionizing Agricultural Production

The development of container farm systems has introduced new possibilities for local food production in urban environments and harsh climates. These controlled environment agriculture units typically utilize grow room shipping containers equipped with advanced hydroponic or aeroponic growing systems. The standardized container dimensions allow for efficient use of vertical space in vertical farming shipping containers, dramatically increasing yield per square foot compared to traditional farming. Climate control systems within container farm units maintain ideal temperature, humidity, and lighting conditions year-round, independent of external weather patterns. This technology enables production of leafy greens, herbs, and even some fruiting crops near population centers, reducing transportation costs and improving freshness while using minimal water resources compared to conventional agriculture.

Vertical Farming Shipping Containers: High-Tech Agriculture

The evolution of vertical farming shipping containers represents the cutting edge of container-based agricultural technology. These intensive production systems stack growing beds vertically within grow room shipping containers, incorporating LED lighting tuned to plant requirements and precise nutrient delivery systems. The controlled environment in vertical farming shipping containers eliminates the need for pesticides while optimizing growth cycles for maximum productivity. Advanced units feature automated monitoring systems that track plant health, environmental conditions, and resource usage, with some incorporating machine learning to continuously improve growing parameters. The mobility of vertical farming shipping containers allows deployment in urban areas, food deserts, and regions with poor soil quality, creating new opportunities for local food security. These systems particularly excel in producing high-value, quick-growing crops with relatively low energy inputs compared to traditional greenhouse operations.

FAQS About Containerized Solutions

What are the main components of a containerized water treatment plant?

A complete containerized water treatment plant typically includes pre-filtration systems, membrane filtration units, chemical dosing equipment, disinfection components, and control systems, all integrated within the container structure. The specific configuration varies based on water source quality and required output standards.

How does a shipping container kitchen meet health regulations?

Properly designed shipping container kitchen installations can meet all health department requirements when equipped with appropriate food preparation surfaces, sanitation stations, temperature control, and ventilation systems. Many jurisdictions classify them similarly to traditional food service establishments.

What crops grow best in container farm systems?

Container farm units are particularly effective for leafy greens, herbs, microgreens, and strawberries. The controlled environment of grow room shipping containers allows for optimization of specific crop requirements, though space limitations make them less suitable for large field crops.

What are the energy requirements for vertical farming shipping containers?

Vertical farming shipping containers require substantial energy for LED lighting and climate control, though advanced designs incorporate energy-saving technologies. Many operators use renewable energy sources to improve sustainability and reduce operational costs.

Can containerized solutions be combined for integrated operations?

Yes, containerized water treatment plant systems can supply clean water to shipping container kitchen operations, while container farm units can provide fresh produce—demonstrating how these modular solutions can create complete, self-contained ecosystems when strategically combined.

This comprehensive exploration of container applications demonstrates their transformative potential across water infrastructure, food service, and agricultural sectors. From life-saving containerized water treatment plant deployments to high-efficiency vertical farming shipping containers, these solutions continue to redefine what’s possible with modular, mobile designs. The combination of durability, standardization, and adaptability ensures container-based systems will play an increasingly important role in addressing global challenges related to water access, food security, and sustainable urban development.