The rapid rise of renewable energy and the increasing demand for grid stability have propelled container battery energy storage systems into the spotlight. These pre-fabricated powerhouses, housed within robust containerised battery storage units, offer unparalleled advantages in scalability, deployment speed, and cost-effectiveness, particularly for large-scale, wholesale applications. However, their apparent simplicity belies the intricate technical design & engineering considerations required to create safe, efficient, and durable systems within the confined space of a standard shipping container battery energy storage container. Success hinges on meticulous integration and optimization across multiple critical domains.

Mastering Thermal Management Container Battery Energy Storage Systems

Effective heat dissipation is arguably the most critical aspect of container battery energy storage system design. Batteries generate heat during charging and discharging cycles, and excessive temperatures accelerate degradation and pose severe safety risks.

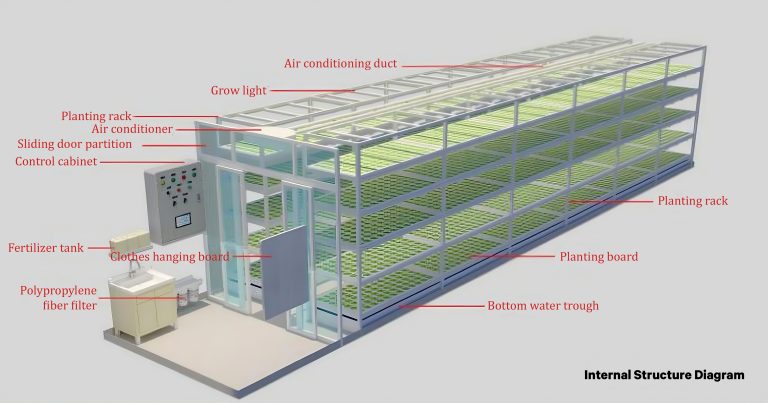

·Cooling Strategy Selection: The choice between air cooling and liquid cooling is fundamental. Air cooling relies on forced convection using fans and ducts; it’s simpler and lower cost but less efficient for high-power density systems, potentially leading to larger temperature gradients. Liquid cooling uses a coolant circulated through cold plates contacting battery modules or racks; it offers superior thermal uniformity, higher efficiency, and better suitability for high-power applications and extreme climates, but adds complexity and cost.

·System Design and Redundancy: The cooling system must be sized to handle peak heat loads under worst-case ambient temperatures. Redundancy is crucial for maintaining safe temperatures even during component failure. Sensors continuously monitor temperatures at multiple points within battery racks and the container ambient.

·Integration and Airflow Optimization: Ductwork, plenums, and fan placement must ensure even airflow distribution across all battery modules to prevent hot spots. In liquid-cooled systems, piping layout, pump sizing, and heat exchanger (chiller) capacity are critical. Ventilation for auxiliary equipment and humidity control also needs integration.

·Climate Adaptability: The containerised battery storage system must operate reliably in diverse environments, from desert heat to arctic cold. Designs must include heating elements for cold-start conditions and enhanced cooling capacity for high ambient temperatures, impacting insulation choices and HVAC specifications.

Integrating Safety and Control Container Battery Energy Storage Systems

Safety is non-negotiable in containerised battery storage. A multi-layered approach combining active and passive systems within the container battery energy storage container is essential.

·Battery Management System: The BMS is the brain monitoring every cell/module for voltage, current, and temperature. It performs critical functions like state-of-charge and state-of-health estimation, cell balancing, and enforcing operational limits to prevent overcharge, over-discharge, and overheating. Redundancy in critical BMS functions enhances reliability.

· Fire Detection and Suppression: Early and reliable detection is key. Systems combine gas sensors , smoke detectors, and temperature sensors. Suppression systems must act rapidly and effectively. Common solutions include aerosol generators, inert gas flooding , or specialized water mist systems designed for lithium-ion fires, integrated directly into the container battery energy storage system.

·Ventilation and Gas Management: Thermal runaway events can produce flammable and toxic gases. Explosion vents designed to safely release pressure and dedicated, sealed exhaust ventilation systems ducting gases away from personnel and equipment are mandatory safety features. Gas detection triggers ventilation and alarms.

·Energy Management System and Controls: The EMS orchestrates the entire system – cooling, safety systems. It executes operational strategies (peak shaving, frequency regulation, energy arbitrage), manages state transitions, logs data, provides remote monitoring/control interfaces, and ensures all subsystems operate harmoniously and safely according to defined protocols.

Frequently Asked Questions About Container Battery Energy Storage System Design

What are the critical certifications for a wholesale-grade container battery energy storage system?

Wholesale deployments demand rigorous certifications. Essential ones include Standard for Energy Storage Systems and Equipment covering the entire system, and adherence to Standard for the Installation of Stationary Energy Storage Systems for fire safety. Local electrical and building codes are also mandatory.

How does the thermal management design impact the overall container battery energy storage system lifespan?

Effective thermal management is crucial for longevity and return on investment. Consistent, optimal operating temperatures significantly slow down battery degradation, preserving capacity and extending usable life, directly impacting the system’s economic viability over its lifetime. Efficient cooling also minimizes parasitic energy losses (power used to run fans/pumps), maximizing the net energy available for revenue generation or cost savings.

Can containerised battery storage units be easily stacked for higher capacity?

Stackability is a key advantage for wholesale scaling. However, it requires careful engineering from the outset. The container battery energy storage container structure must be reinforced to handle both the internal weight and the load from stacked units. Stacking also impacts cabling, fire suppression integration (requiring inter-unit suppression links), and potentially access for maintenance. Designs must explicitly account for stacking loads and provide safe connection interfaces.

What are the main engineering challenges in integrating transformers within the battery energy storage container?

Integrating a Medium Voltage transformer adds significant complexity. Key challenges include managing the heat dissipation from transformer losses alongside battery heat, requiring sophisticated combined cooling solutions. Physical size and weight demand substantial space and structural reinforcement. Acoustic noise mitigation becomes critical. Electrical clearances and safety barriers within the confined space must strictly adhere to HV safety standards. Vibration during transport must also be addressed.

How crucial is the container battery energy storage system in ensuring safety?

The BMS is the primary guardian against catastrophic failure. It continuously monitors every critical parameter (voltage, current, temperature per cell/module) and enforces strict operational safety limits, preventing conditions like overcharge or over-discharge that can lead to thermal runaway. It enables early fault detection, triggers alarms, initiates safe shutdown procedures, and provides vital data for diagnostics. A robust, redundant is absolutely fundamental to the safe operation of any container battery energy storage system.

Designing and engineering a container battery energy storage system is a complex feat of multidisciplinary integration. Successfully packing immense power into a standard shipping container battery energy storage container requires meticulous attention to structural integrity, thermal dynamics, electrical conversion efficiency, and multi-layered safety systems. Every aspect – from the spatial arrangement of battery modules and the choice of air cooling or liquid cooling, to the sophistication of the BMS and the robustness of fire suppression – must be optimized to create a reliable, safe, and high-performing containerised battery storage solution. For wholesale deployments, where scalability, rapid deployment, and long-term reliability are paramount, this rigorous engineering foundation is not just beneficial; it is essential. The ability to deliver these sophisticated systems consistently at scale hinges on deep technical expertise and precision manufacturing.

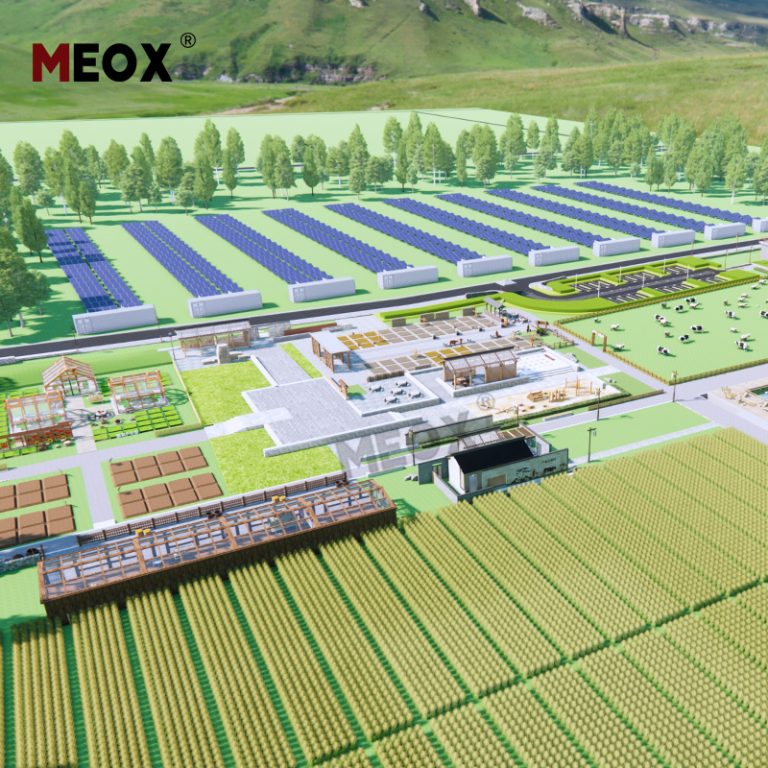

Suzhou Zhongnan Intelligent Equipment Co, Ltd. leverages its core strength as a manufacturing enterprise specializing in designing and producing both standard and specialized containers to contribute significantly to this ecosystem. With complete manufacturing facilities, a professional production team, and skilled design technicians, Zhongnan focuses on delivering high-quality, reliable container battery energy storage containers. Their expertise encompasses the entire range, including the ability to engineer custom containerised battery storage solutions tailored to the specific technical demands and challenging operating conditions required by large enterprises and research institutions for their wholesale energy storage projects. This capability ensures the physical vessel housing these complex systems meets the highest standards of durability, safety, and functionality.