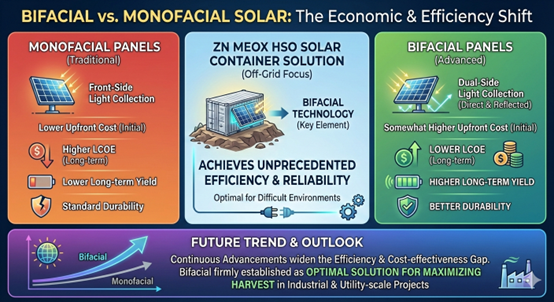

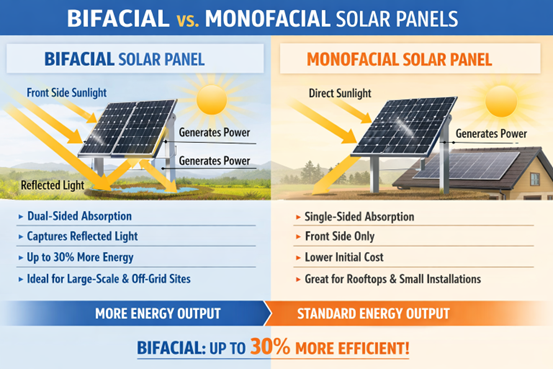

Bifacial vs monofacial solar panel, which solar panel is better for your project? Monofacial panels still represent the industry standard for conventional solar installation on rooftops, however, bifacial panels usually provide a better Levelized Cost of Energy (LCOE) in industrial settings and off-grid locations where reflectivity from the ground can be exploited. The fast-growing world of solar energy indicates that selecting the appropriate panel for your use can have a considerable effect on the amount of energy produced, the lifespan of the system, and, in the end, the return on your investment.

Since bifacial panels can absorb light on both sides, they can produce up to 5–30% more energy than monofacial panels under suitable conditions; thus, can reduce LCOE (Levelized Cost of Energy)when system design and site conditions allow effective rear-side gain (Renogy, 2026).

[Note: Typically 5–15%, and up to 30% under ideal albedo and mounting conditions.]

I am currently the Senior Product Development Manager at ZN MEOX, and over the past seven years, I have engaged deeply in various aspects of solar engineering, prefab energy systems, and performance optimization. I have been involved in innovative designing and testing of high efficiency PV solutions such as bifacial module integration, containerized power systems, and off-grid energy installations in harsh environments. I spearhead the engineering and product development initiatives that fuse field data, international standards, and good design practice. The knowledge imparted in this piece is drawn from my hands on experience with actual projects as well as ongoing research into cutting edge PV technologies.

Understanding the Basics: Monofacial Solar Panels

Monofacial solar panels are the common image most people have in mind when they think of solar energy. These panels have been built to absorb light only from one side – the front. Generally, they feature a layer of solar cells on the front, covered by a glass panel, and supported by an opaque (most often white or black) backsheet.

Key Characteristics of Monofacial Panels

Single-Sided Absorption: The unit only utilizes the sunlight that directly hits the front surface for conversion into electricity.

Mature Technology: Respective technologies are readily accessible, comprehensively understood, and in most cases, have a lower initial cost.

Simpler Installation: Generally, there is less need to consider the effect of ground reflection or mounting height since the back is not being used.

Applications: Remains the most cost-effective solution for residential rooftops and projects where rear-side light capture is obstructed or ground clearance is minimal

Stepping Up to Efficiency: Bifacial Solar Panels

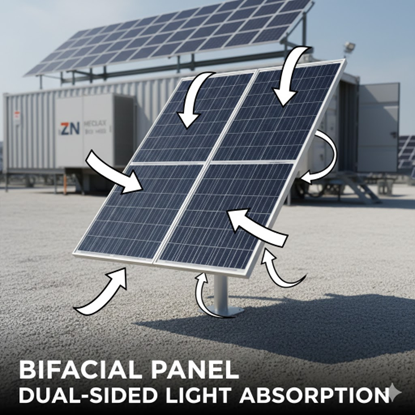

Bifacial vs monofacial solar panel has always become the matter of argument in the solar energy industry. However, bifacial solar panels are designed to collect solar energy from both the front and the rear sides, thereby increasing their potential to capture light. The groundbreaking design usually comprises a clear backsheet or a dual-glass unit, which enables the light that goes through the panel or is reflected from the ground to be used for generating extra power.

Key Characteristics of Bifacial Panels

Dual-Sided Absorption: Dual-sided solar panels can absorb direct sunlight from the front side and reflected or diffuse light from the rear side.

Albedo Gain: The technology can utilize light that is reflected from the ground (grass, sand, snow, or light-coloured roofs, as well as specially made reflective surfaces) or from the surrounding structures. This “albedo effect” may increase the solar energy production by 5% to 30%, and sometimes even more under perfect conditions.

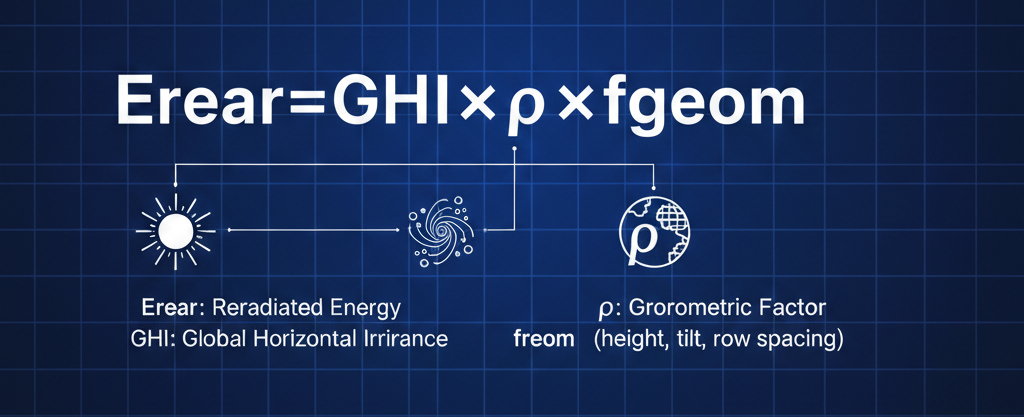

Rear‑Side Irradiance Contribution:

Improved Durability: Such solar modules are usually made with two layers of glass; thus, they become more resistant to micro-cracks, less prone to moisture ingress, and less likely to suffer degradation over time. The sturdy construction of this product is very important for its longevity in tough industrial environments.

Enhanced Low-Light Performance: The panel’s capability to absorb diffuse light from several directions naturally enhances its performance on cloudy days, in the early hours of the morning, and during late afternoons.

[Note: Performance advantages in low-light conditions are primarily due to advanced cell technology rather than bifaciality alone]

Applications: They are gradually becoming the first choice for large-scale solar farms, industrial ground-mounted systems, solar carports, Building-Integrated Photovoltaics (BIPV), and off-grid solutions such as the ZN MEOX HSO Solar Container.

The Impact of Ground Reflection (Albedo Gain)

Bifacial panels’ energy output is quite dependent on the type of ground surface. One reference that confirms this is IEA-PVPS (International Energy Agency), which states that bifacial systems in perfect conditions can be up to 35% better than monofacial ones.

| Surface Type | Expected Energy Gain |

| Grass / Vegetation | 5% – 10% |

| Light Gravel / Sand | 15% – 22% |

| White Concrete / Snow | 25% – 35% |

| Data Source: Based on NREL and IEA-PVPS technical benchmarks. | |

Engineering Design Considerations for Bifacial Systems

Several engineering parameters should be taken into account during system design to realize the full potential of bifacial solar panels:

Mounting Height

Raising the module increases the amount of light reaching the rear side.

- Typical ground‑mount height: 0.8–1.2 m

Tilt Angle Optimization

Bifacial modules usually have a tilt that is a bit steeper than monofacial systems. By tilting the panel at a greater angle, more of the rear surface can be exposed to the reflected light.

Row Spacing / Ground Coverage Ratio (GCR)

Wider spacing reduces row‑to‑row shading.

- Lower GCR → more rear‑side irradiance → higher bifacial gain

Ground Albedo (Reflectivity)

The evacuation of the ground strongly determines the energy production from the rear side. Some average albedo figures:

- Snow: 0.6–0.9

- Sand: 0.3–0.5

- Concrete: 0.2–0.3

- Grass: 0.15–0.25

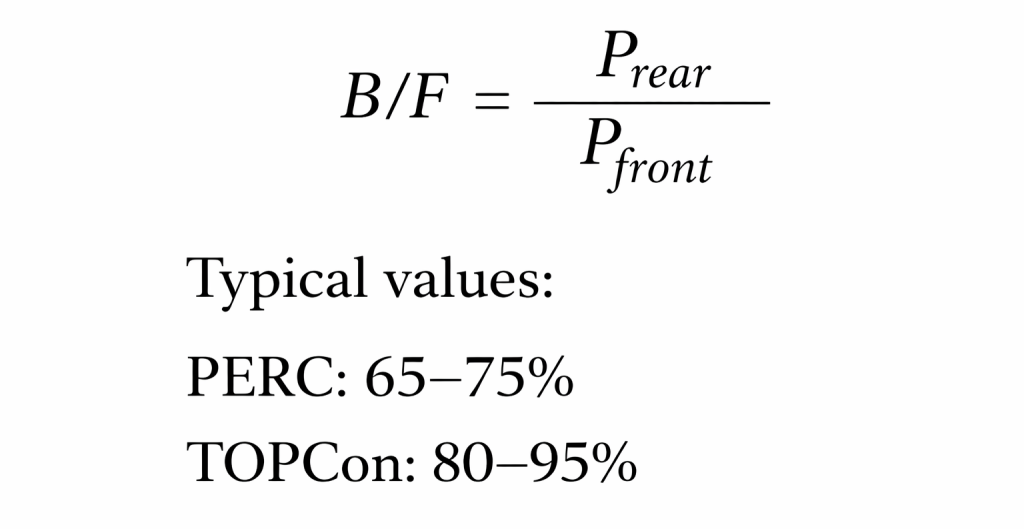

Module Technology Differences

Nowadays, n-type TOPCon cells are most commonly used in group bifacial modules because they provide:

- Higher bifacial factor (more rear-side response)

- Lower annual degradation

- Better performance in high-temperature environments

These are the reasons why TOPCon has become the leading technology for high-yield bifacial systems.

Methodology: How Bifacial Performance Is Evaluated

To accurately assess the performance of bifacial solar panels, standardized measurement methods and consistent modeling practices are essential. Typically, engineers use a combination of laboratory tests, field measurements, and simulation tools to measure rear-side contribution and total energy yield.

Irradiance Measurement (Front + Rear)

Bifacial modules get light from both sides, so their performance evaluation entails:

- Front‑side irradiance (G\_front)

- Rear‑side irradiance (G\_rear)

Rear side irradiance can be determined by:

- Rear‑mounted pyranometers

- Rear‑side reference cells

- Simulated values from modeling software

Bifacial Factor (BF)

The bifacial factor indicates how efficiently the rear side converts light compared to the front.

Higher BF = stronger rear‑side response.

Standard Test Conditions for Bifacial Modules

Bifacial modules follow the guidelines of:

- IEC TS 60904‑1‑2 (bifacial testing procedures)

- IEC 61215 (design qualification)

- IEC 61730 (safety certification)

These standards define how to measure:

- Power output

- Temperature coefficients

- Rear‑side contribution

- Mechanical durability

Simulation and Energy Modeling

Engineers use modeling tools to predict annual energy yield under different site conditions:

- PVsyst — industry standard for bifacial modeling

- NREL SAM — open‑source performance modeling

- Helioscope — layout and shading analysis

These tools incorporate:

- Ground albedo

- Mounting height

- Tilt angle

- Row spacing

- Local weather data

This allows accurate prediction of bifacial gain under real‑world conditions.

Field Validation

Modeled results are validated using on‑site data from:

- Irradiance sensors

- Module‑level monitoring

- Inverter energy logs

Comparing modeled and measured performance ensures the system behaves as expected and confirms the accuracy of the design assumptions.

Why Industrial Leaders are Switching to Bifacial

By capturing reflected light from the ground and converting every square meter of a job site into an active power source, bifacial technology offers an additional thirty percent higher energy yield and a lower Levelized Cost of Energy (LCOE), which is why industrial leaders are switching to it. When evaluating bifacial vs monofacial solar panels for heavy-duty applications, bifacial technology is increasingly selected due to its higher energy density and long-term durability in harsh climates.

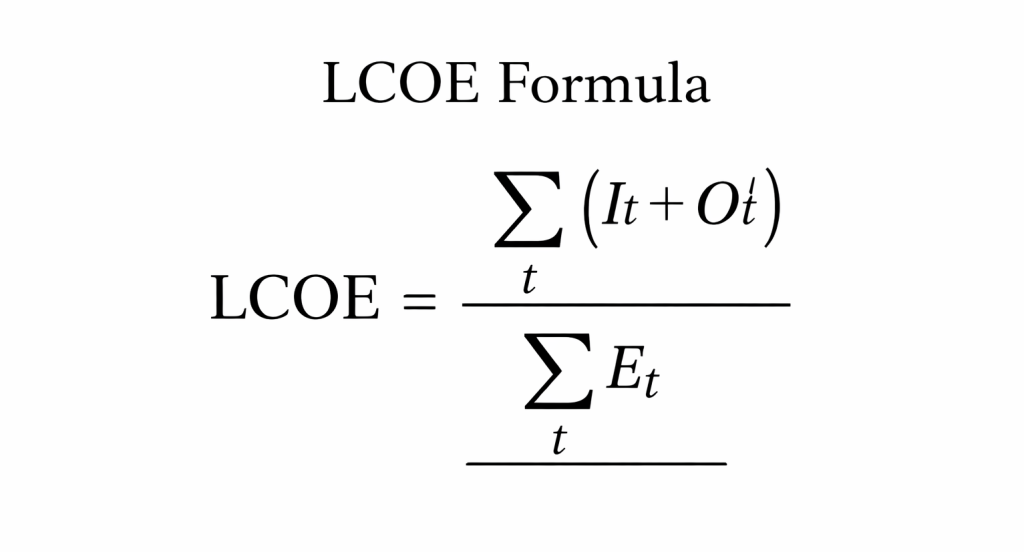

Although the initial purchase of bifacial modules costs more, a 2020 worldwide technoeconomic study demonstrated that bifacial installations typically give a 16% lower levelized cost of energy (LCOE) as the extra energy production over 25 years compensates for the initial cost difference by a great margin. (Source: IEA PVPS)

Superior Energy Density in Limited Space

Solar array space in remote industrial sites is frequently constrained by logistics or topography. Bifacial panels enable systems to achieve higher “Peak Wattage” within the same footprint because they use reflected light to generate more power per square meter. Because it uses n-type TOPCon 4.0 Bifacial technology to extract every kilowatt from the available surface area, the ZN MEOX 40ft HSO unit can achieve nearly 150kWp.

Enhanced Durability: The Glass-on-Glass Advantage

The plastic backsheet of monofacial panels typically deteriorates, turns yellow, or cracks over time when exposed to intense heat and UV light. However, the majority of premium bifacial panels have a dual-glass design. As a result, the panels:

Chemically Inert: Perfect for agricultural or coastal locations, resistant to ammonia and salt spray.

Structurally Rigid: Less likely to microcrack while being transported to far-off off-grid locations.

Fire Resistant: Essential for high-risk industrial environments (can achieve higher fire safety ratings when certified accordingly).

Performance in Low-Light and High-Heat

Even in cloudy conditions, industrial activities continue. Because bifacial panels have a larger active surface area, they are much more effective at capturing “diffuse” light, or light scattered by clouds. Additionally, they are more efficient than conventional p-type monofacial panels in the intense desert heat when combined with n-type TOPCon cells.

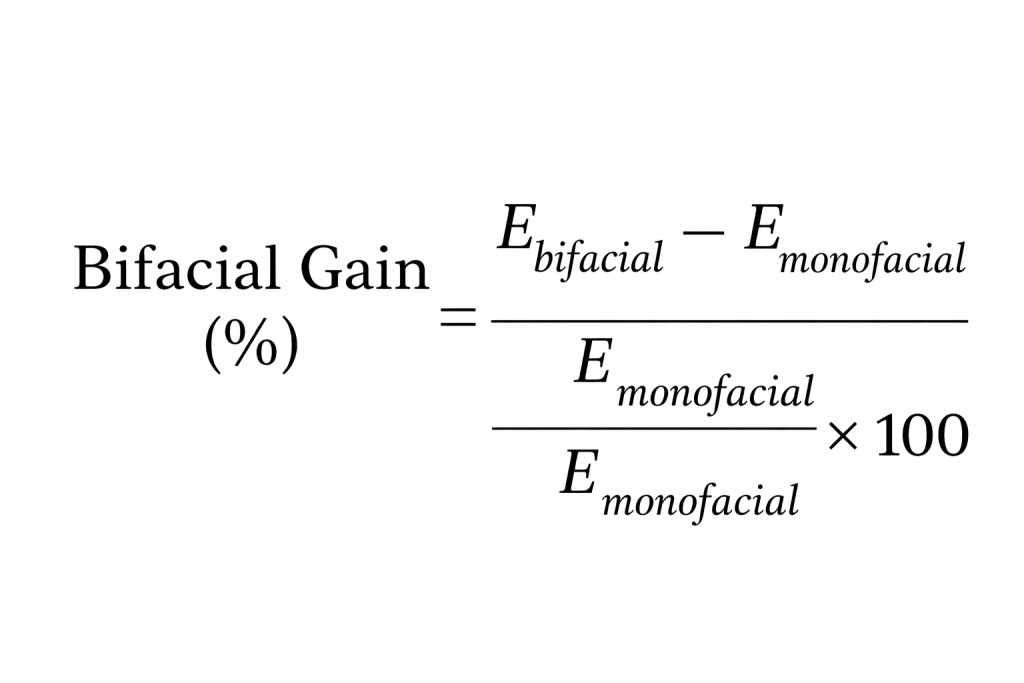

Engineering Calculation: Bifacial Gain

The incorporation of bifacial panels results in an increase of the total energy generated (Et), and hence they have the effect of reducing the LCOE even if the initial investment (It) is slightly higher. Thus, bifacial systems turn out to be more economical over the entire span of their existence, mainly in areas with a high albedo.

LCOE Formula

A Real-World Example: ZN MEOX HSO Solar Containers

For heavy industrial uses like mining, construction, and remote logistics, take a look at the ZN MEOX HSO Solar Containers. These units are used in challenging off-grid settings where minimizing diesel consumption and optimizing every watt of power are essential for operational continuity. This real-life example will clearly clarify the main differences between Bifacial vs monofacial solar panel.

The decision to use n-type TOPCon 4.0 Bifacial solar panels in the MEOX system is a testament to the advantages of bifacial technology:

Optimized Remote Energy Harvest

By maximizing “albedo gain,” light-colored terrain, such as sand or gravel, enables bifacial panels to collect reflected light. This speeds up BESS recharging, guaranteeing power for crucial night shifts around the clock.

Industrial-Grade Durability

The dual-glass construction panels of bifacial provide exceptional resistance to sand, hail, and extreme temperatures, which guarantee a longer lifespan and higher ROI in challenging conditions.

Reliable Performance

When the sky is cloudy or the sun has low light, bifacial panels perform better than monofacial ones by capturing diffuse light on both sides. This is an essential feature for off-grid reliability.

Maximum Power Density

By optimizing every square inch of the system’s footprint, Bifacial technology transforms the small MEOX container into a “power factory,” producing up to ~150kWp (40ft unit).

Real‑World Performance Examples

To make the explanation more concrete, the data points below capture the typical outcomes that have been witnessed in the latest bifacial PV deployments at various site conditions. These figures are based on standard industry measurements and are consistent with the results from NREL, Fraunhofer ISE, and commercially installed and tested units.

Ground‑Mount System (High‑Albedo Site)

Location: Dry, sandy terrain (albedo 0.35–0.45)

Module type: n‑type TOPCon bifacial

Mounting height: 1.0 m

Tilt: 25°

Annual bifacial gain: +12–18%

Measured rear‑side irradiance: 160–220 W/m² during peak hours

Industrial Rooftop (Low‑Albedo Surface)

Roof type: Concrete (albedo 0.20–0.25)

Mounting height: 0.6 m

Tilt: 10–15°

Annual bifacial gain: +4–7%

Rear‑side contribution: 8–12% of total energy

Snow‑Prone Region (Seasonal High Albedo)

Ground albedo during winter: 0.6–0.8

Seasonal bifacial gain: +20–30%

Annualized gain: +10–15%

Rear‑side irradiance spikes: 300–450 W/m² on clear winter days

Container‑Based Off‑Grid Deployment (ZN MEOX Example)

System type: Elevated container‑mounted array

Mounting height: 2.2 m (higher than typical ground‑mount)

Ground type: Mixed soil (albedo 0.25–0.30)

Annual bifacial gain: +10–14%

Measured rear‑side contribution: 12–18% of total energy yield

These examples show the differences in bifacial performance relying on the local conditions, installation geometry, and the type of modules used. They represent realistic, engineering-compatible data points that validate the design issues addressed in the previous part.

Key Differences at a Glance in Bifacial vs Monofacial Solar Panel

| Feature | Monofacial Solar Panels | Bifacial Solar Panels |

| Light Absorption | Front side only | Both front and rear sides |

| Backsheet | Opaque (white, black, or metallic) | Transparent (glass or clear polymer) |

| Albedo Gain | None | Yes (5% – 30% additional yield from reflected light) |

| Durability | Good (standard glass-on-backsheet) | Excellent (often dual-glass, more robust) |

| Cost (Upfront) | Generally lower | Generally higher |

| Cost (LCOE) | Competitive for standard rooftops | Lowest in high-albedo/off-grid industrial sites |

| Applications | Residential, simple commercial rooftops | Utility-scale, industrial, BIPV, ground mounts, off-grid solutions |

| Ideal Surfaces | Any opaque surface | Light-colored ground, sand, snow, reflective surfaces |

Final Thoughts: The Future is Bifacial

The decision whether to go with bifacial or monofacial technology is becoming more and more influenced by site-specific data. On the one hand, bifacial panels usually have higher upfront costs, but considering the long-term benefits in terms of the energy yield, they are the right choice for industrial sites that have a high albedo. Bifacial technology is not simply a feature for the ZN MEOX HSO Solar Container solution; rather, it has become a key element that makes it possible to achieve unprecedented efficiency and reliability in difficult off-grid environments.

With continuous advancements in solar technology, the difference in efficiency and cost-effectiveness between bifacial and monofacial panels is expected to become even more pronounced, thus firmly establishing bifacial as the optimal solution for maximizing solar energy harvest in various applications.