The demand for flexible infrastructure has changed the food service industry dramatically. Food businesses today no longer rely solely on permanent brick-and-mortar structures. In fact, they are increasingly looking for fast, durable, and versatile solutions. Modular portable kitchen units have become the most popular option for rapid deployment. Such units offer a superb food preparation environment in any location. These units are a smart option for remote mining camps or even a quick urban pop-up because the modular way remains highly efficient without compromising quality.

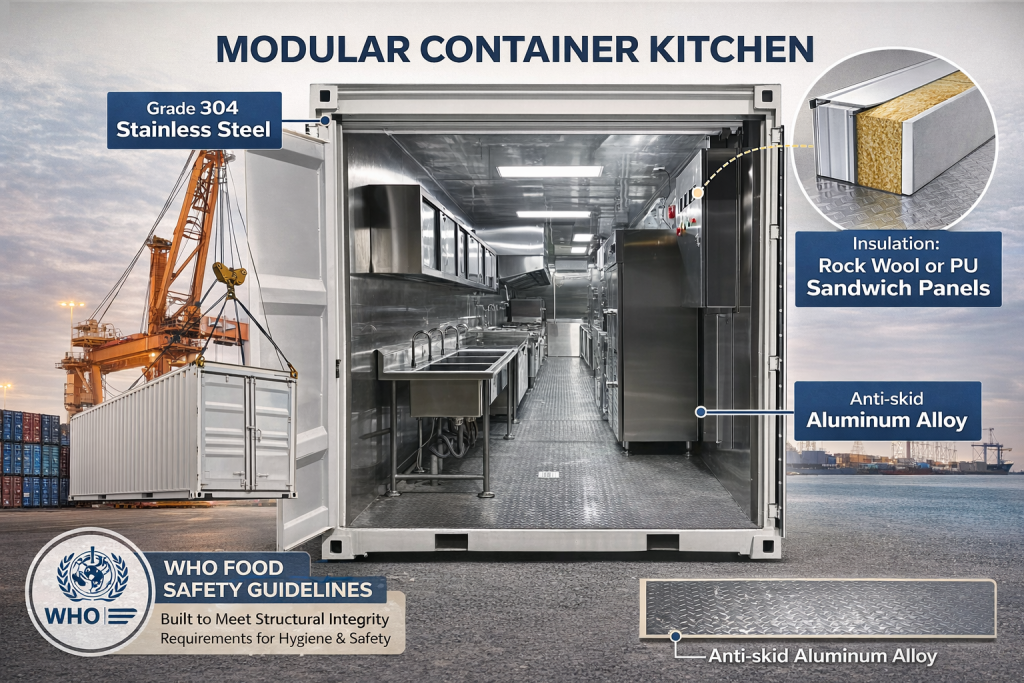

Fig. 1: A 40ft Standard Modular Portable Kitchen Unit

I work as the Senior Technical Project Manager at MEOX. I have more than 7 years of experience in modular structural engineering and prefab design having delivered 300+ containerized units across hospitality, mining, and infrastructure projects in Asia-Pacific and North America.. This article is a reflection of my work in the field. I want to illuminate the technical criteria that characterize top-notch mobile infrastructure for the readers.

Understanding the Structure of Modular Portable Kitchen Units

BMarko Structures explains that modular portable kitchen units are also called as ‘Cargo Containers’ or simply ‘Shipping Container Kitchen’. Standard shipping containers can be turned into fully functional modular portable kitchen units by adding insulation, cutting out doors and windows, and installing necessary equipment such as kitchen appliances and an HVAC system. Dual-redundant HVAC units were sized using peak sensible heat load calculations based on equipment wattage, occupancy, and ambient temperature.

The frame is the base for quality. To withstand the stresses of transport and environmental changes, a professional unit is needed. Mainly, top-notch Modular Portable Kitchen Units are fabricated of high-strength steel. This guarantees adequate stiffness to carry heavy kitchen equipment.

Fig. 2: Technical Anatomy and Material Standards of Modular Portable Kitchen Units

The inside has to conform to stringent hygiene regulations. As per the food safety guidelines of the World Health Organization (WHO), surfaces should be non-porous and easy to clean. Surface material selection follows WHO food hygiene recommendations for non-porous, cleanable food-contact environments. That’s the reason stainless steel has become the industry’s go-to material for wall cladding. Besides being heat-resistant, it also inhibits the growth of bacteria.

| Component | Material Used | Benefit |

| Main Frame | High-strength structural steel | Structural integrity during transport |

| Interior Walls | Grade 304 Stainless Steel | Hygiene and heat resistance |

| Flooring | Anti-skid Aluminum Alloy | Safety and easy drainage |

| Insulation | Rock wool or PU Sandwich Panels | Thermal regulation and fire safety |

Table 1: Primary Material Specifications of Modular Portable Kitchen Units

Thermal Efficiency and Climate Control

Cooking releases a lot of heat. Good insulation is a must if you want to keep the staff comfortable. Besides, it helps to shield the external structure from bending. Rock wool of high density is the material mostly utilised because it resists ignition. Polyurethane (PU) is a great alternative, especially in a cold climate. It is capable of excellent heat saving.

However, ventilation is as important as insulation. If you are looking for highly efficient systems, then a modular kitchen with an industrial exhaust hood should be your pick. These exhausts work with the smoke and the fats to help keep the air fresh and the risk of a fire at bay. The use of energy-efficient LED lights not only provides sufficient lighting in the workspace but also helps to reduce energy consumption.

Technical Integration and Utilities

The quality of a kitchen highly depends on its utilities. Among them are the plumbing and electrical systems that should be pre-installed. This makes it possible for the delivered kitchen to be ready to use immediately. The electrical wiring should be in line with the international safety standards, for instance, IEC 60364 (Electrical installations of buildings), so as to guarantee its compatibility with the power grids worldwide.

| System | Feature | Specification |

| Electrical | Distribution Box | 220V/380V options |

| Lighting | LED Fixtures | Waterproof and dustproof |

| Plumbing | Integrated drainage | Stainless steel pipes |

| Windows | Double-glazed sliding | Thermal efficiency |

Table 2: Technical Utility Overview of Modular Portable Kitchen Units

Fig. 3: Integrated Utility Infrastructure in Modular Portable Kitchen Units

| System | Reference Standard |

| Electrical | IEC 60364 / NFPA 70 |

| Fire insulation | EN 13501-1 |

| Structural steel | EN 1993 / ASTM A36 equivalent |

| Food hygiene | WHO food safety guidelines |

Why Choose Durable Prefab Mobile Kitchens?

Rapid deployment is one of the biggest benefits. Standard buildings (construction) usually take several months. On the other hand, Modular Portable Kitchen Units can be completed in just a few weeks. Moreover, they offer a great deal of customization. For example, the layout can be rearranged according to different cooking requirements.

Moreover, they are extremely durable. They are designed to withstand demanding outdoor environments when installed per design assumptions. Utilizing galvanized steel, it can remain rust-free even in coastal areas. Such durability is definitely a wise financial decision for expanding companies.

| Metric | Performance Level |

| Fire Rating | Grade A (Non-combustible) |

| Wind Resistance | Up to 120 km/h |

| Service Life | 15 – 20 years |

| Portability | Standard crane/forklift points |

Table 3: Performance Metrics of Modular Portable Kitchen Units

Wind resistance values were taken from structural calculations using the specific loading of EN 1991-1-4 for wind actions on lightweight steel structures. Fire ratings illustrate the non, combustibility classification of the insulation materials which has been tested to EN 13501-1.

Case Studies: Experience in the Field

Case Study 1: Urban Expansion in Seattle

Location: Seattle, USA

Time: Summer 2022

The Problem: Blue Wave Catering, a leading name in catering, landed a large contract for a six-month waterfront festival. They required a full-service kitchen but were not allowed to install permanent structures on the site. Moreover, they were short on time; getting started, they had only five weeks.

The Solution: I collaborated with Sarah, Director of Operations at Blue Wave Catering, to come up with a custom 40ft Modular Portable Kitchen Unit. We laid out the unit in a way that would allow the team to prepare tons of seafood quickly. The unit had the floors reinforced to hold heavy refrigeration, and the electrical grid was customized so that it could easily handle several industrial ovens.

Testimonial: “Teaming up with the MEOX really changed our game. The Modular Portable Kitchen Units came exactly as we had specified. We were able to start cooking within 48 hours after delivery. The stainless-steel interior made health inspections a walk in the park. It was much stronger than the temporary trailers we had used before. It did not look like a container; it was more like a real building. The project passed local health inspections on first submission, with no corrective actions required”

— Sarah Jenkins, Director of Operations, Blue Wave Catering

Case Study 2: Remote Mining Camp Infrastructure

Location: Darwin, Australia

Time: February 2023

The Problem: The site was in a deserted area away from the town, where the weather was so hot that the temperature often rose above 40 °C. They wanted a kitchen that would be able to serve 150 workers every day and at the same time, keep the staff cool and follow the food safety standards in really hot weather.

The Solution: I was the leader of the engineering team in the endeavor to integrate high-density PU insulation of specialist grade into the Custom commercial container units. We put in a dual-redundant HVAC system so that the kitchen would remain cool even if one of the units stopped working. Also, the building was strengthened to endure the severe dust and wind conditions of the Australian outback.

Testimonial: “Of course, in a place like Darwin, it’s only a matter of time before the equipment blows up, right? But the High-performance modular kitchen systems Alex came up with for us have not seen any fault so far. The insulation is so good that we pretty much saved 30% on our cooling costs compared to what we thought. Robert and the team brought us a tough, reliable product that our chefs really like working with.”

— Robert Walsh, Logistics Manager, Outback Mining Corp.

To learn more about the Modular Portable Kitchen Units, please visit our product page here.

Conclusion

Modular portable kitchen units are the perfect compromise between mobility and industrial-grade performance. Such units aren’t just temporary solutions; they are sturdy, long-lasting assets. Choosing top-quality materials such as galvanized steel and stainless steel for the interiors, a business will not only secure the safety of the environment but also the efficiency of the work. If you want a dependable, tailor-made kitchen solution, MEOX has the engineering skills to make your dream project a reality.

Frequently Asked Questions (FAQs)

How quickly can a Modular Portable Kitchen Unit be installed after delivery?

Once the unit is delivered and set up on level ground, typically, the connection to water and electricity only takes a few hours. They are built for quick deployment.

Do Modular Portable Kitchen Units meet international food safety standards?

Yes. Through the use of non-porous stainless-steel walls and anti-skid aluminium flooring, the units comply with the hygiene standards for food prep areas as set by the World Health Organization (WHO).

Are Modular Portable Kitchen Units designed for repeated relocation?

Certainly. The structural steel frame is designed to be lifted and moved repeatedly. So if you are a business that relocates your operation from one site to another seasonally, these would be perfect for you.

Disclaimer: All performance data presented are based on factory testing, engineering calculations, and completed project specifications. Final compliance depends on local authority approval, site conditions, and applicable regional codes.

Each MEOX container undergoes various performance tests before leaving the factory. To see our testing process, watch this video: