Transporting hazardous materials requires strict compliance with international safety standards, and that’s where the DG container—short for Dangerous Goods container—plays a crucial role. Designed to meet stringent regulations, DG containers ensure that flammable, toxic, corrosive, or reactive substances can be shipped safely across land, sea, or air. Businesses that handle chemicals, energy materials, pharmaceuticals, and industrial compounds rely heavily on DG containers to prevent leakage, contamination, and accidents throughout the shipping process.

A DG container is essentially a specially engineered unit built to carry materials classified as dangerous under the IMDG (International Maritime Dangerous Goods) Code. Unlike standard cargo containers, dangerous goods containers feature reinforced steel structures, high-grade sealing, improved ventilation, and safety fittings that minimize risks during loading, transportation, and storage. For suppliers and logistics companies handling hazardous materials, DG containers are not optional—they are a legal requirement.

What Makes Hazardous Material Shipping Containers Different?

Hazardous material shipping containers are built with enhanced safety considerations to protect both people and the environment. These containers may include spill containment flooring, internal lining, corrosion-resistant coatings, fire-retardant insulation, and pressure-release mechanisms. Every design element serves the same purpose: to ensure the container can withstand extreme conditions without compromising its structural integrity.

Many industries—chemical manufacturing, oil and gas, pharmaceutical production, and waste management—depend on hazardous material shipping containers for secure transport. A single breach during shipment could cause environmental contamination, fire hazards, or toxic exposure, making container engineering critically important. Regulations require DG containers to undergo rigorous testing for pressure, vibration, impact resistance, and fire safety, making them one of the safest forms of material transport available.

Types of Dangerous Goods Containers and Their Applications

There is no one-size-fits-all approach when it comes to dangerous goods containers. Depending on the substances being shipped, containers can be designed for:

- Flammable liquids

- Corrosive chemicals

- Toxic and infectious substances

- Radioactive materials

- Oxidizing agents

- Pressurized gases

For example, DG containers for flammable liquids incorporate explosion-proof ventilation systems, while those for corrosive materials include anti-corrosion linings. Containers for compressed gases may require reinforced walls and temperature-control measures. The adaptability and engineering precision of dangerous goods containers ensure that each material type receives the protection it requires to travel safely across various modes of transport.

Regulatory Requirements for DG Containers

Every DG container must comply with international and regional standards, including:

- IMDG Code

- ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road)

- RID (Regulations concerning the International Carriage of Dangerous Goods by Rail)

- ISO container manufacturing standards

Compliance determines whether the container can legally operate in global shipping networks. This includes specifications such as:

- Proper labeling and placarding

- Correct structural reinforcements

- Fire and heat resistance

- Spill containment systems

- Proof of pressure and stability testing

- Material compatibility validation

Companies that ship hazardous goods must ensure their containers meet these codes; otherwise, cargo may be rejected at ports, delayed, or deemed unsafe for transport.

Why Choosing the Right DG Container Manufacturer Matters

Not all containers are engineered with equal quality. Choosing a reliable manufacturer is essential when safety, compliance, and durability are at stake. A poorly built DG container can lead to chemical spills, costly shipping delays, or regulatory violations. Businesses should assess factors such as:

- Manufacturing certifications

- Engineering experience

- Quality control processes

- Customization capabilities

- Material specifications

- Long-term durability

The right container ensures long-term performance, predictable maintenance, and consistent safety compliance, making it a crucial investment for operations involving dangerous goods.

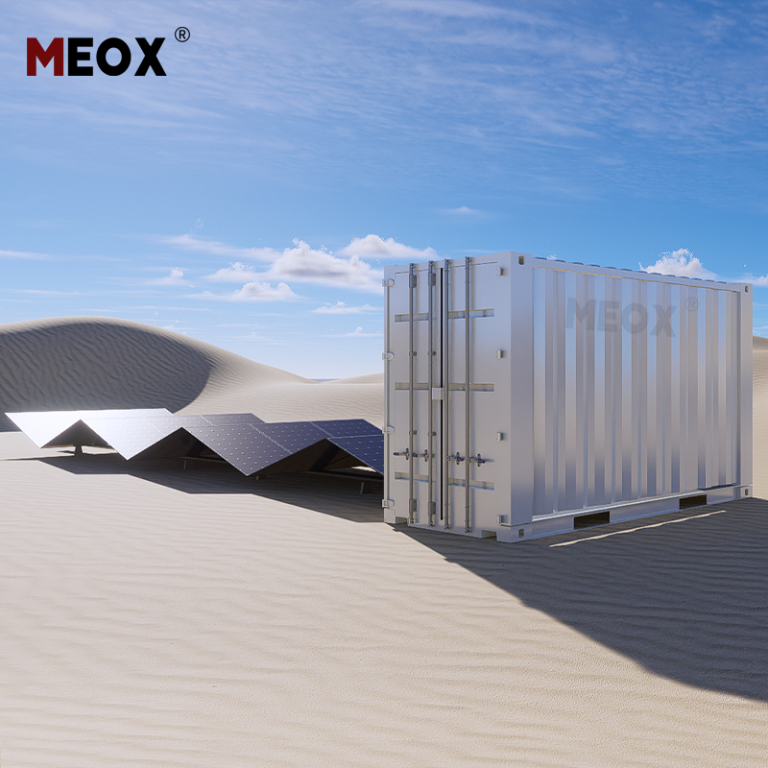

ZN-Meox: A Trusted Manufacturer of DG Containers and Special Containers

ZN-Meox, operated by Suzhou Zhongnan Intelligent Equipment Co., Ltd., is recognized for its engineering strength, manufacturing capacity, and commitment to quality. As a company specializing in both standard containers and complex special containers, ZN-Meox provides dependable solutions for enterprises and research institutions requiring containers that meet strict working-condition demands.

What sets ZN-Meox apart?

- Professional design technicians who understand international DG regulations

- Complete manufacturing equipment supporting precision engineering

- Custom-built DG container solutions tailored to unique hazardous material requirements

- Strong sealing performance, durable steel structures, and corrosion-resistant finishes

- Flexibility to design special-purpose containers for chemical plants, labs, power companies, and logistics firms

- Reliable after-sales support and long-term service partnerships

ZN-Meox dangerous goods containers are engineered to deliver safety, compliance, and operational reliability—traits that are essential when transporting hazardous materials around the world. Every unit is manufactured with strict quality oversight to ensure safe handling, long-term durability, and regulatory approval.

Conclusion: DG Containers Are Essential for Safe Hazardous Materials Transport

A DG container is more than a transport vessel—it is a safety system designed to protect workers, the environment, and valuable cargo. With increasing global demand for chemical products and industrial materials, the importance of reliable hazardous material shipping containers and professionally engineered dangerous goods containers continues to grow.

For businesses requiring dependable DG container solutions, ZN-Meox provides the specialized manufacturing expertise needed to ensure compliance, durability, and safe transport in all working conditions.

About the Author

Michael Ren — Industrial Logistics & Container Engineering Specialist

Michael Ren is a technical writer and container engineering consultant with over 12 years of experience in hazardous materials logistics and special-container design. He focuses on helping manufacturers and global transport companies understand compliance, container technology, and modern safety standards. He collaborates with industry leaders like ZN-Meox to deliver accurate, practical insights into container innovation and engineering.